Best 15 Differences Between High Speed and sectional Warping

Introduction:

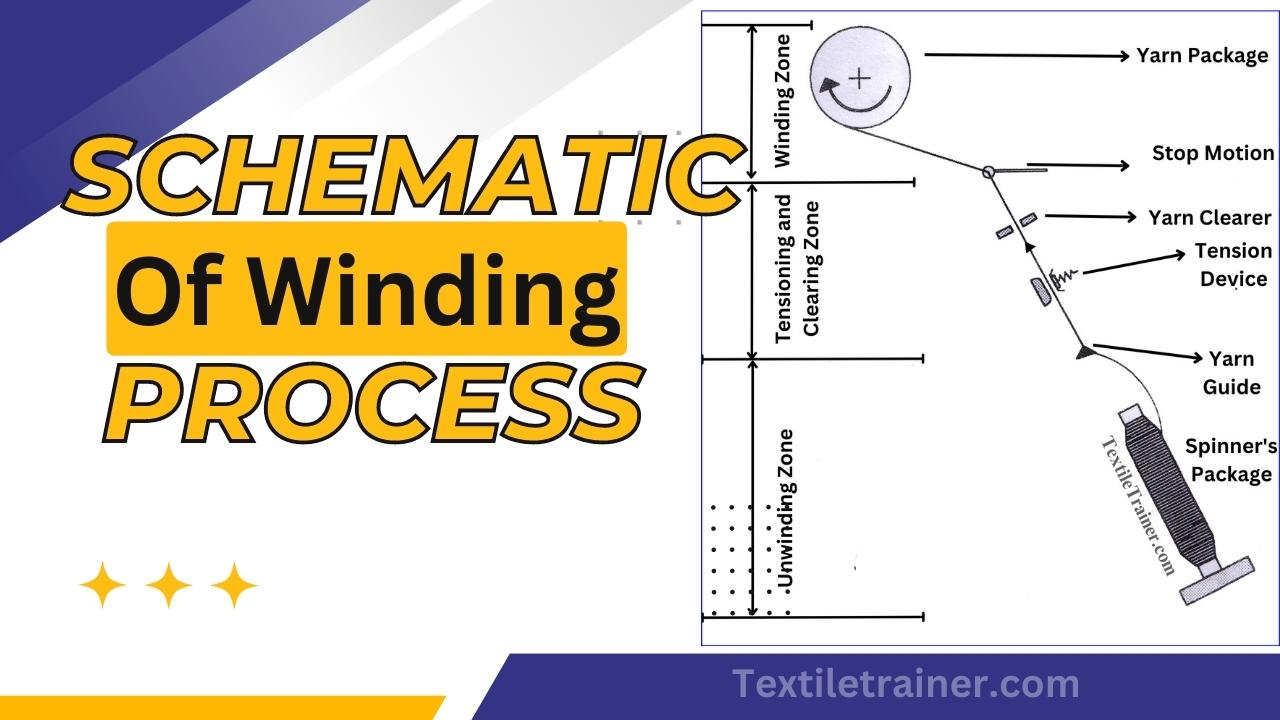

Throughout this article, it is discussed how high speed and sectional warping differ from each other and features of different types of warping. The warping process occurs when many yarns are transferred from a creel of single-end packages onto a beam or section beam to form a parallel sheet of yarns. Today’s warping machines can process All kinds of material, including filaments, staples, monofilaments, smooth and textured yarns, silk, and other synthetic yarns. For yarns that generate static electricity, an eliminator device is usually recommended.

The warp beam installed on a weaving machine is called a weaver’s beam. Even though weaver’s beams can contain several thousand ends, they are rarely produced in one operation. They are prepared in different ways, depending on their purpose. Warping terminology is quite different in different regions, and sometimes the same term may be used to refer to the same process in different industries or regions. In warping, the weaver prepares the beam for setting up on the weaving machine. high speed and sectional warping

It is generally accepted that there are three different methods of warping, each employing a different technology:

- High speed or beam or direct warping.

- Sectional or pattern or indirect warping.

- Ball warping.

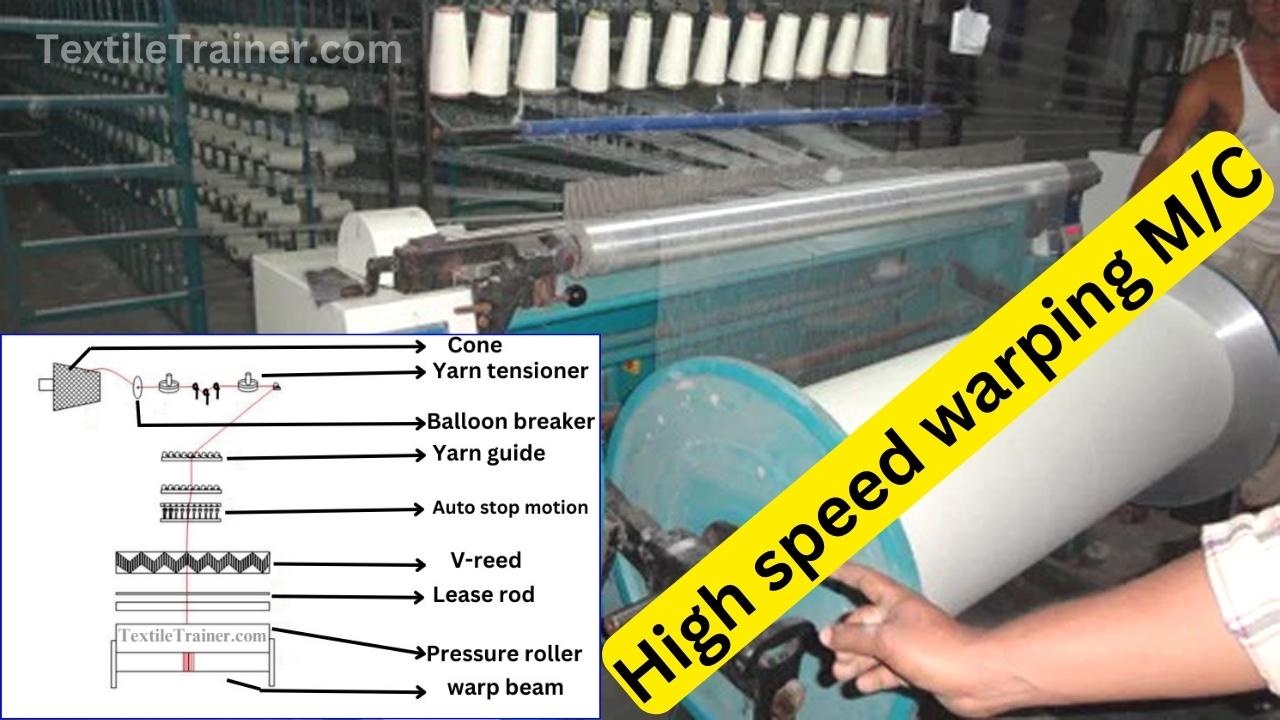

1. High speed warping:

This method of producing cotton warps is mainly used when the yarn to be woven requires the application of starch, which is applied in the following yarn preparation process known as sizing, after which it is sent to the loom for weaving. In addition, as mentioned above, continuous filament yarns can also be used in producing beams with this method.

Features of high speed warping:

- A large amount of warp yarn can also be used to produce warp beams.

- The warp beam is produced as soon as the sizing process has been completed.

- It is used to produce warp beams from single yarns.

- In addition, it is used to produce large quantities of common fabrics.

- In high-speed manufacturing, this process is used.

- High-speed warping utilizes a simple flanged bobbin as a beam.

2. Sectional warping:

A sectional warping technique is used to weave towels with stripes when the yarn is wound on the beam in sections, beginning at the tapered end of the beam. Multiple yarn colors can be incorporated into the weaver’s beam using sectional warping. The drum of the beam has a cone with a slight angle that prevents the yarn from slipping off. Sectional warping is crucial when it comes to making yarn-dyed striped towels.

Features of sectional warping:

- Sectional warping is used to make fancy fabrics.

- It can also be used to produce warp beams by using warp yarns which do not need any sizing materials to be applied before fabric weaving. In other words, they do not require any material for sizing.

- It has a low production rate, which makes it a costly process.

- The warp beam is made by twisting yarn, which is used to produce warp beams.

- In this case, it is not possible to maintain a uniform tension of the warp yarn.

- There is a drum that is used in this warping process.

3. Ball Warping:

In a ball warping process, warping is carried out as a rope over a wooden ball while it is woven together. For dyeing, the yarn ends are braided and collected (between 350 and 500 ends) and then twisted into an untwisted rope. The rope is wound onto a long log cylinder on a machine called a ball warper.

Features of ball warping:

- The purpose of ball warping is to prepare rope so that it can be dyed in the rope dyeing machine.

- In the process of ball warping, magazine type creels are used.

- There is a long cylinder called a log on which the rope is wound.

- It is generally accepted that the rope length on a log is 12830 meters.

- Ball warping is primarily used for the production of denim fabrics.

Differences between high speed and sectional warping

| S/N | High speed warping | Sectional warping |

| 01 | During high speed warping, uniform tension is maintained. | There is no uniform tension available in this method. |

| 02 | In this case, a single yarn is used. | The yarn used here is twist yarn. |

| 03 | It produces a greater amount of product than other methods. | There is a lower amount of production with this method than with high speed warping. |

| 04 | In this case, a larger amount of warp yarn is required. | The amount of warp yarn required here is quite small. |

| 05 | In terms of cost, it is a very cheap process. | Ultimately, this is a process that is very costly. |

| 06 | This process is highly used and it is very much in demand. | The process is not used as a high speed warping process. |

| 07 | This is a machine that is used to produce warp beams from a large amount of warp yarn. | This is a machine that is used to produce warp beams from a small amount of warp yarn. |

| 08 | It is mostly used for the processing of fibres such as cotton, linen, woolen and worsted yarns. | it is also used for fibres such as silk and man-made fibres. |

| 09 | Weaver’s beams are produced after the sizing process has been completed. | The weaver’s beams are produced after the warping process has been completed. |

| 10 | High speed warping is used to produce grey and colored fabric named common fabric. | Sectional warping is used to produce fancy fabric. |

| 11 | In this case, cheese and cone winding packages are used. | In this case, a flanged bobbin is used. |

| 12 | There is a creel capacity of more than 12000 in this case. | In this case, the creel capacity is between 300 and 400 |

| 13 | In this case, there is a high level of production speed. | The production speed of the warping process is lower than that of the high speed warping process. |

| 14 | There is only one stage involved in this process. | There are two stages involved in this process. |

| 15 | In general, it is a popular process. | Unlike high speed warping, it is not very popular. |

In summary, high-speed and sectional warping are two different ways of preparing yarn for weaving. Warping at high speeds involves setting up the entire warp beam separately from the loom, allowing for quick beam changes, yarn selection flexibility, and efficient high-volume production. Alternatively, sectional warping involves the warp beam being mounted directly onto the loom and the threads wound in sections, allowing for variable warp length adjustment and frequent pattern changes. Mainly high-speed warping is used to make the common color grey fabric. On the other hand, sectional warping is used to make fancy fabric.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- Belal, P. D. (2016). Understanding Textiles for a Merchandiser. Dhaka: LB Graphics & Printing.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Rahman, M. M. (2008). Fabric Manufacturing Technology. Dhaka: Books Fair Publications.

- V. Gordeev, P. V. (1982). Cotton Weaving. Russia: Mir Publishers Moscow.