Experiment Name:

Lab Report: Study on material passage diagram of jute finisher carding machine in jute spinning.

Introduction:

A jute card’s primary function is to transform reeds into a uniform supply of fibrous material that can then be drafted and twisted into yarn. Perhaps the most dramatic change in jute appearance occurs at the cards; when it is passing into the breaker card, the reeds from the plant stems can easily be identified, and the whole feed appears coarse and uneven, but by the time it passes through the carding machine, the jute appears to have changed dramatically. It has been transformed into a thin web of separate fibers emerging as a fleece which is then condensed into a sliver. In addition to this essential task, the cards also begin to reduce weight by drafting and leveling the weight by doubling. Since jute fibers are long and hard, two carding machines are used to make them soft, namely the breaker card and finisher card.

Objectives:

- To know about jute finisher carding machine.

- Come to learn different parts of jute finisher carding machine.

- To know working principle of jute finisher carding machine.

Compared to the Breaker carding machine, the Finisher carding machine produces slivers that are uniform and regular in length and weight. With the addition of more rollers, staves, pin arrangement and speed, the Finisher carding machine is the same as the Breaker carding machine. On this machine, four to twelve slivers obtained from the Breaker carding machine are fed. This material is then sent to the drawing section.

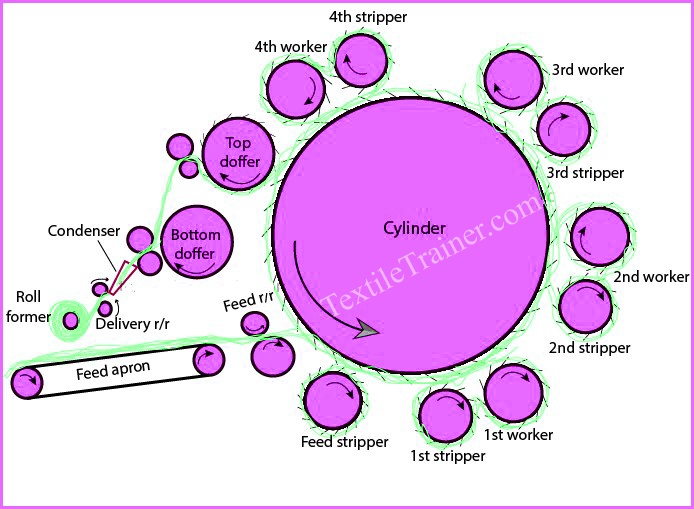

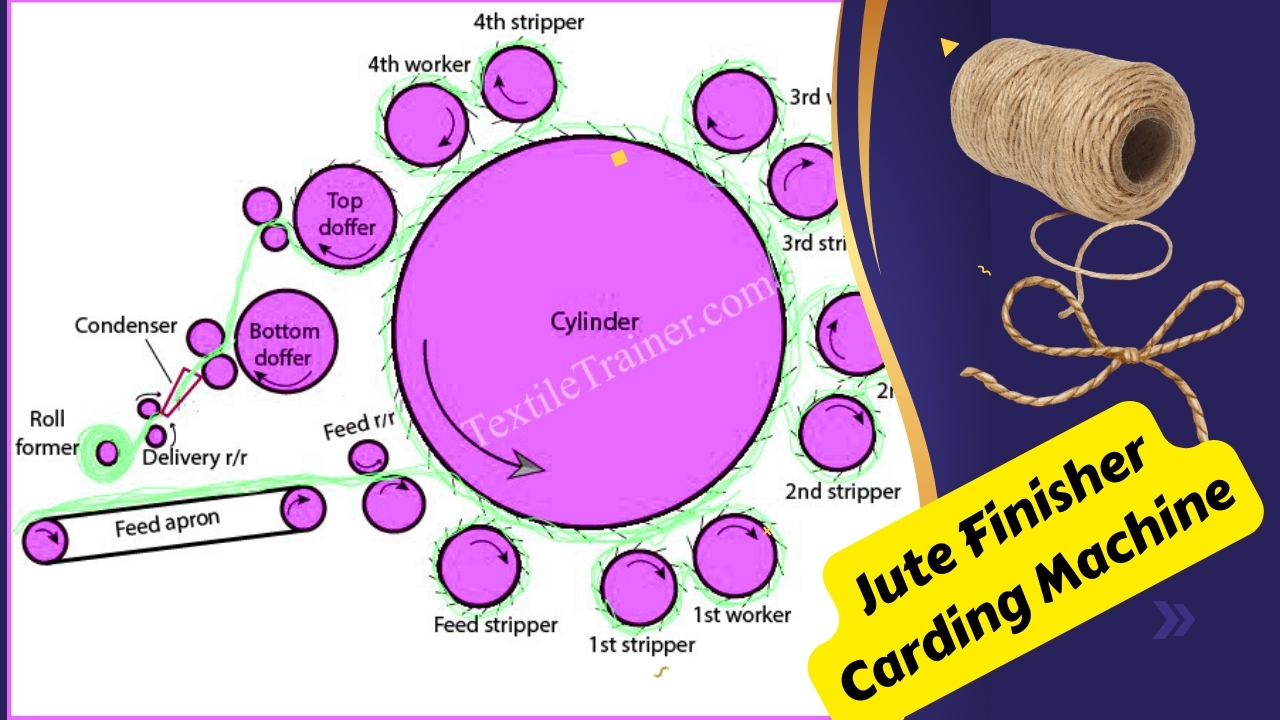

Main Parts of Jute Finisher Carding Machine:

| 1= Motor | 9= Worker (4 pair) |

| 2= Motor shaft | 10= Doffer (2 pair0 |

| 3= Feed Sheet | 11= Drawing roller |

| 4= Feed roller | 12= Drawing press roller |

| 5= Pin feed roller | 13= Condenser |

| 6= Big cylinder | 14= Delivery roller |

| 7= Feed stripper roller | 15= Delivery press roller |

| 8= Striper (4 pair) | 16. Roll former |

Working Principle of Jute Finisher Carding Machine:

- Finisher cards have a feeder that acts like a receiver, and 10-12 slivers from the breaker card are placed side by side in the feed.

- This process uses two types of feed systems, the shell feed system and the double pinned feed system.

- Fibers contact the top feed roller, pin feed roller, and feed stripper. The pin feed roller and feed stripper have pins pointing toward the back, resulting in a limited amount of carding action.

- The fibers are then transferred to the worker. The pin direction between the cylinder and worker is point-to-point, and the cylinder speed is significantly higher than the worker’s, making the carding process easier.

- After the fibers are combed between the workers and the stripper, the stripper guides the fibers to the surface of the cylinder, approaching the second worker-stripper pair.

- As the same carding action is repeated along the second, third, and fourth pairs of workers and strippers, the fibers are thinned down and individualized.

- The fibers come in contact with the doffer after leaving the fourth pair of worker-strippers. Since the pin direction of the doffer and cylinder are opposite, a combing action occurs.

- Fibers are transferred to the second doffer, drawing rollers, and delivery rollers after passing through the drawing rollers.

- As a final step, the finisher sliver is compressed and delivered as a roll.

Conclusion:

The finisher card is an important step in the production of high-quality jute yarn. It makes the jute fibers more straight and parallel through the action of a pair of rollers. Thanks to our teacher for providing us with this information.

You May Read:

- Jute Softener Machine: Easy Way Material Passage Diagram.

- Easy Working Principle of Jute Spreader Machine.

- Working Principle of Jute Breaker Carding Machine.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description

wow, awesome blog.Really thank you! Cool.