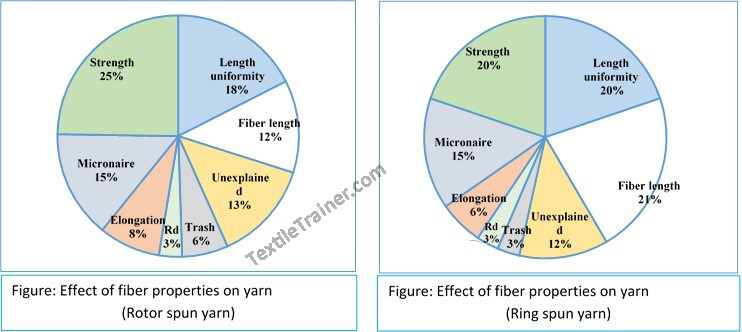

Mainly Yarn quality in spinning depend on fiber quality. 7 important fiber properties that influence yarn quality is describe in simple way.

Raw material represents about 50-75% of the manufacturing cost of a short-staple yarn. This fact alone is sufficient to indicate the significance of the raw material for the yarn producer. The influence becomes more apparent when the ease of processing one type of fiber material is compared with the difficulties, annoyance, additional effort, and decline in productivity and quality associated with another similar material.

1.Some Important Fiber properties that influence yarn quality in spinning:

- Fiber length

- Fiber strength

- Fiber stiffness.

- Fiber cleanliness.

- Fiber color.

- Fiber maturity.

- Fiber fineness

1.1 Fiber length:

Fiber length is an important property that influences yarn quality in spinning. It is the top one of the three most important fiber characteristics. It defined the spinnability of the fiber. The staple length has been the basis for trading cotton for over a century. But single fiber length has been the basis for process control of spinning operation. Fiber length influence:

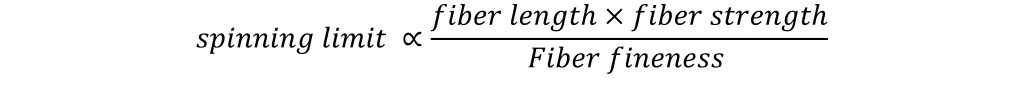

- Spinning limit: spinning limit indicates the range of spinnable count from a set of fiber parameters. It also depends on the spinning system. It can be stated as below:

From the above equation, we find that if fiber length increases, then the spinning limit also increases.

- Yarn strength: if the fiber length increase, the yarn strength will increase.

- Yarn evenness: If fiber length increases, the yarn evenness will increase during drafting. Suppose fiber length and uniformity index increase, then production of drafting irregularity will decrease due to a reduction in floating fiber.

- Handle of the product: fiber softness depends on it. If the fiber length increases, the handle of the product increases.

- Luster of the product: If fiber length increases, the luster of the product increases.

- Yarn hairiness: If fiber length increases, the yarn hairiness will decrease, and hairiness increases due to shortening in length.

- Productivity: If fiber length increases, productivity will increase.

1.2 Fiber strength:

Fiber strength is another essential property that influences yarn quality. Strength is very often the dominating property. This can be seen from the fact that nature produces countless fibers, most of which are not usable for textiles because of inadequate strength. The minimum strength for a textile fiber is approximately 6 CN/tex. Some significant breaking strengths of fibers are:

| Cotton fiber | 15-40 CN/tex |

| Polyester fiber | 35-60 CN/tex |

| Wool fiber | 12-18 CN/tex |

If fiber strength increases, yarn, and fabric strength will increase. Fiber strength is more sensitive to the new spinning system. Generally, the strength of cotton fiber bundles is measured and expressed by the unit pressly index. The following scale of value is used:

| Range | Grade |

| Under 70 | Weak |

| 70-74 | Fair |

| 75-80 | Medium |

| 81-86 | Strong |

| 87-92 | Very strong |

| Above 93 | Excellent |

Fiber strength influence:

- Spinning limit: if fiber strength increases spinning limit will increase.

- Productivity: if fiber strength increase, yarn productivity will increase.

- Yarn hairiness: if fiber strength increases, yarn hairiness will decrease.

- Yarn strength: if fiber strength increases, yarn strength will increase to a significant extent.

- Yarn evenness: if fiber strength increases, yarn evenness will increase to a small extent.

1.3 Fiber stiffness

Fiber stiffness plays a significant role when rolling, revolving, and twisting movements are involved. A fiber that is too stiff has difficulty in adapting to these movements. Fibers that need to be stiff enough have too little springiness. They do not return to shape after deformation. They have no longitudinal resistance.

In most cases, this leads to the formation of neps. Fiber stiffness depends on fiber substance and the relationship between fiber length and fiber fineness. Fibers having the same structure and diameter will be stiffer the shorter they are:

1.4 Fiber cleanliness.

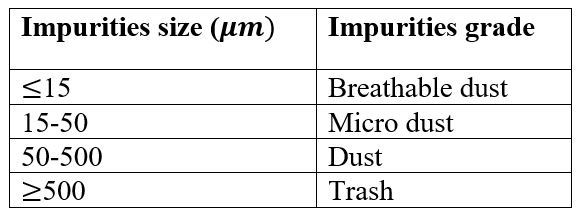

The fiber cleanliness property is not fiber’s inherited property but an inclusive one. Fiber length or strength etc., are the inside properties, but the trash or dust, etc., are the outside properties. The fiber cleanliness is generally expressed by impurities level. The impurities, in addition to usable fibers cotton stock, contain foreign matter of various kinds. These are:

- Vegetable matter: seed, husk, leaf, stem fragments, wood fragments

- Foreign matter: metal fragments, cloth fragments.

- Mineral matter: sand, earth, ore dust picked up in transport, dust picked up in transport.

- Sticky contamination: honeydew, grease, oil, tar, additives.

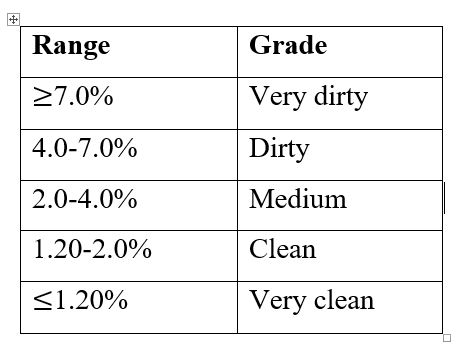

Range of impurities:

The fiber cleanliness i.e. impurities property is described by the definition of following parameter of AFIS:

1.5 Fiber Color:

Fiber color is an essential property. Fiber color has to be considered during spinning. Because how well a yarn or fabric will dye or bleach depend on fiber color. Generally, the color of cotton fiber is extra white, white, spotted tinged, yellow stained, etc. The color of cotton is determined by the degree of reflectance (Rd) and yellowness (+b) in the HVI.

1.6 Fiber maturity.

The cotton giber consists of a cell wall and lumen. The maturity index is dependent upon the thickness of this cell wall. Cotton stock without unripe fibers is unimaginable. Unripe fibers have neither adequate strength nor adequate longitudinal stiffness.

The influence of fiber maturity is:

- Yarn strength: The matured fiber has the maximum strength. Therefore, the higher the fiber maturity, the higher the realization efficiency of fiber strength to yarn strength.

- End breakage: Due to the lower translational efficiency of fiber strength to yarn strength for the immature fibers, end breakage in the spinning at the ring frame and the post-spinning at weaving increases.

- Nippiness: The dead fiber leads to low-maturity fiber. The lower the maturity ratio, the higher the degree of nepping of fiber in the process.

- The proportion of short fibers: Low matured fiber lead to higher breakage during processing esp in the blow room and card frame. This breakage phenomenon leads to a higher short fiber content in the process.

- Shade variation: The dye take-up rate varies depending on the maturity ratio. Low-matured fiber takes up a lower quantity of dye, and the dye take-up ratio for matured fiber is higher.

1.7 Fiber fineness:

Fineness usually is one of the three most important fiber characteristics. A multitude of fibers in the cross-section provides high strength and better distribution in the yarn. The fineness determines how many fibers are present in the cross-section of a yarn of a given thickness.

Fiber fineness influence:

- Spinning limit: if fiber fineness increases, the yarn spinning limit will increase.

- Yarn evenness: if fiber fineness increase, yarn evenness will increase.

- Drape of the fabric product: If fiber fineness increases, the drape of the fabric increase.

- Handle: handle of the fabric will be better if fiber fineness increases.

- Yarn hairiness: If fiber fineness decreases after the optimal working range, yarn hairiness will increase.

- Yarn strength: If fiber fineness increase, yarn strength will increase.

- Luster: if fiber fineness increases, the luster of yarn will increase.

- Productivity of the process: Productivity will decrease if fiber fineness increases.

- Yarn twist limit: if fiber fineness increase after the optimal working range, the twist limit will decrease.

Reference

- Mohammed Farhad Mahmud Chowdhury “Manual of Short Staple Spinning” March ,2016

- Prof. Dr. Engr. Shah Alimuzzaman Belal”Understanding Textile for a Merchandiser” May, 2016

- Md. Sajjak Hossain “Introduction to Textile Engineering” January ,2014

Thanks for the blog. Really Cool.