1.What is fiber?

Fiber: Important fiber properties are describe in this article. The word fiber or fiber comes from the Latin word fibra. Fiber or fiber is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The most robust engineering materials often incorporate fibers, for example, carbon fiber and ultra-high molecular weight polyethylene. But all fiber is not textile fiber. To be textile fiber, fiber has some special properties. Textile fibers are materials of natural or artificial origin that can be converted into yarn and fabric for clothing and domestic and industrial purposes by interlacing or interloping. In other words, textile fiber is a class of natural or manufactured materials with some special properties, i.e., spin ability or spun-able, high length-to-width ratio, sufficient strength, flexibility, dyeing ability, and cohesiveness, stiffness, ability to resist, good elongation properties.

2. Fiber Properties:

The properties of textile fiber may classify into three kinds. Such as:

- Physical properties.

- Chemical properties.

- Mechanical properties.

2.1 Physical Properties:

The physical properties are mentioned below are worth considerable for a textile fibers.

- Length of fiber(Cm/Inch)

- Tenacity/specific length. (Gram/Denier)

- Fineness of the textile fiber.(mic-value)

- Specific gravity.(G/cc)

- Extension(%)

- Elastic recovery(%)

- Swelling and water retention (%)

- Glass transaction temperature(Tg)

- Specific heat

- Pilling behavior.

- Limiting oxygen index(LOI)

- Moisture regain(%) and Moisture content(%)

- Elongation.

- Fibre breaking length.

- Fiber maturity(%)

- Crystalline melting point(Tm)

- Thermal conductivity

- Durability

- Cohesiveness.

- Uniformity

2.2 Chemical Properties:

- Solubility in organic salt.

- Solubility in aqueous salt.

2.3 Mechanical Properties:

- Rigidity

- Elasticity

- Strength

- Extensibility

3. Important Fiber Properties:

Some important properties of cotton is describe below:

3.1 Length of Fiber:

The length of fiber is the essential property of fiber. The length of the fiber must be considerably more significant than the diameter. The fiber producer sells fibers as a staple, filament, or filament tow. Staple fibers are short fibers measured in cm or inch. The length of the natural fiber, except for silk, are mostly some millimeter up to server cm long. The length ranges from 2 to 46 cm or 3/4 inch to 18 inches. On the other hand, man-made fibers are filaments form. Filaments are long and continuous fiber strands of indefinite length. Generally, filaments are measured in miles or km. Filaments may be either monofilament, where only one filament is used, or multi-filament, where more filaments are used. Another form of fiber length is filament tow. Filament tow, produced as a loose rope of several thousand fibers, is crimped or textured and cut to staple length.

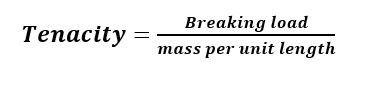

3.2 Tenacity:

Tenacity is the second necessary property of textile fiber. Tenacity, or tensile strength, is the ability of a fiber to withstand a pulling force. Tenacity is measured by securing both ends of the fiber in clamps and measuring the force needed to break or rupture the fiber. Breaking tenacity for a fiber is the force, in grams per denier or tex, required to break the fiber. A fiber’s strength depends on the length of the polymer chain. The degree of orientation of these polymer chains, the strength, and types of the forces of attraction between the polymer chains. The longer a polymer chain is, the higher the degrees of orientation and crystallization. The tenacity of glass fiber is the highest of all other fibers. The tenacity of glass fiber is about 9.6/6.7 gm/denier. The tenacity of acetate is the lowest of all other fibers. The tenacity of acetate fiber is about 1.2-1.4 gm/denier. Cotton fiber has widely used all world. The tenacity of cotton fiber is about 3.5-4.00 gm/denier.

We can provide measurement of fiber by the following law:

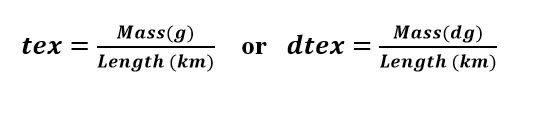

3.3 Fineness of fiber:

Fiber fineness usually is one of the three most important characteristics. The fineness of fiber is defined in many ways. A multitude of fibers in the cross-section provides high strength and better distribution in the yarn. The fiber fineness determines how many fibers are present in a cross-section of yarn of a given thickness. Additional fibers in the cross-section provide additional strength and better evenness in the yarn. About 30 fibers are required at the minimum in the yarn cross-section, but there are usually over 100. One hundred is approximately the lower limit for almost all new spinning processes. This indicates that fineness will become still more important in the future. For yarns and fibers, fineness is usually measured by the ratio of mass to length.

For man-made fiber dtex is used.

3.4 Specific Gravity:

Specific gravity is a measure of fiber weight per unit volume. Lower-density fibers can be made into the thick fabric that is more comfortable than high-density fibers made into heavy fabrics. It is usually expressed in grams per cubic centimeter. The specific gravity of cotton fiber is 1.50-1.55 g/cm3. The specific gravity of polyester fiber is 0.4 g/cm3, the lowest specific gravity of all other fibers.

3.5 Elastic recovery and elongation:

When a fiber is subjected to a small force, it may exhibit almost perfect elasticity. Elasticity is the property of a fiber to recover its original length after stretching caused by a load. The elastic recovery of textile fiber means the ability of a fiber to return to its original dimension after applying load. It is measured as the percentage of return to the actual length. Elastic recovery varies with the amount of elongation and with the length of time the fabric is stretched. Fibers with poor elastic recovery tend to produce fabrics that stretch out of shape. Fibers with good elastic recovery tend to produce fabrics that maintain their shape. Conversely, elongation refers to the degree to which a fiber may be stretched without breaking. It is measured as percent elongation at the break by measuring the change in length and comparing that to the original length.

3.6 Moisture regain and moisture content:

A textile product should be comfortable when it is worn or used. Comfortable of fabric depends on the absorbency of fiber. Absorbency is the ability of a fiber to take up moisture from the body or from the environment. It is measured as moisture regain, where the moisture in materials is expressed as a percentage of the weight of the moisture-free materials. The term of regain is used for moisture absorption in a fiber. This is the amount of moisture present in textile materials expressed as the percentage of the oven dry weight of the textile. This dry mass is the constant weight of the textile obtained after drying at a temperature of 1050 C to 1100 C. on the other hand, the moisture content is the mass of moisture in fiber and is expressed as a percentage of the total weight. It measures the amount of water held under any particular set of circumstances. The moisture content is always lower than the regain.

3.7 Cohesiveness:

This characteristic refers to the ability of the fiber to stick together in yarn manufacturing processes. Cohesiveness indicates that fibers tend to hold together during yarn manufacturing due to the longitudinal contour of the fiber or the cross-section shape that enables the fiber to fit together and entangle sufficiently to adhere to one another.

3.8 Resiliency:

Resiliency is the ability of a fiber to return to its original shape after bending, twisting, or crushing. Resilient fibers usually produce resilient fabrics. An easy test for resiliency is to crunch a fabric in your hand and watch how it responds when your open your hand. Resilience is the property of a fiber that enables it to recover from a particular load or stretched position.

3.9 Thermal retention:

Thermal retention is the ability of a fiber to hold heat. Because people want to be comfortable regardless of the weather. A low level of thermal retention is favored in hot weather, and a high level in cold weather. The property is affected by fiber, yarn, fabric structure, and fabric layering of fabrics.

3.10 Uniformity:

The uniformity of fiber is one of the most important properties of the fiber. The regularity of the final yarn depends on fiber uniformity. To minimize the irregularity in the final yarn, the fibers must be similar in length and width, i.e., be uniform. The inherent variability in the natural fiber can be averaged out by blending natural fibers from many different batches to produce a uniform yarn.

References

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L.B graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning . Dhaka: Granthanir Prokashoni.

- Corbman, B. P. (1983). Textiles Fiber to Fabric. New York: Mc Graw Hill.

- Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

Fantastic blog article.Much thanks again. Great.

thanks for your comment.

Really informative blog post.Much thanks again. Really Cool.

Please support us….

Thanks for the blog.Really looking forward to read more. Cool.

thanks too….please support us….

wow, awesome blog article.Really thank you! Keep writing.

Keep visit our site….

Very neat article. Cool.

keep visit our site..

I really liked your blog. Great.

keep visit our site….

Looking forward to reading more. Great blog post.Really thank you! Awesome.

please share our article…

Thank you for your post. Really Cool.

keep visit our site….

I truly appreciate this article.Really thank you! Will read on…

thanks too.

Fantastic blog post. Awesome.

Thanks

Thank you for your article.Really thank you! Great.

Major thankies for the article. Want more.

Im thankful for the blog.Really looking forward to read more. Fantastic.

wow, awesome blog post. Really Cool.

keep visit our site….

I truly appreciate this blog.Really looking forward to read more. Will read on…

Thanks too……

Appreciate you sharing, great article.Much thanks again. Cool.

thanks too…..

Thanks for sharing, this is a fantastic blog article.Thanks Again. Really Cool.

A big thank you for your blog.Really looking forward to read more. Awesome.

Thank you ever so for you post.Much thanks again. Great.

Major thankies for the blog post.Much thanks again. Want more.

A round of applause for your article post.Really looking forward to read more. Cool.

Say, you got a nice article.Thanks Again. Awesome.

I cannot thank you enough for the article.Really looking forward to read more. Want more.

Im thankful for the article.Really looking forward to read more. Awesome.

I really like and appreciate your article post.Thanks Again. Much obliged.

Appreciate you sharing, great blog.Really thank you! Awesome.

Great post. Awesome.

A big thank you for your article post.Really thank you! Fantastic.

Major thanks for the article post.Really thank you! Keep writing.

Im obliged for the blog. Cool.

A big thank you for your article post.Really looking forward to read more. Fantastic.

wow, awesome article. Really Cool.

Im obliged for the article post.Much thanks again. Want more.

I really liked your blog article.Really thank you!

A big thank you for your blog.Really thank you! Want more.

Thanks a lot for the post.Much thanks again. Will read on…

This is one awesome article post. Want more.

I appreciate you sharing this blog article.Thanks Again. Want more.

I loved your blog article.Thanks Again. Really Great.

Thanks a lot for the blog article.Really looking forward to read more. Want more.

Very good article. Cool.

I am so grateful for your article.Much thanks again. Awesome.

I am so grateful for your article post.Really thank you! Want more.

I loved your blog post. Much obliged.

Hey, thanks for the blog.Really thank you! Awesome.

A round of applause for your blog.Really thank you! Cool.

Very good blog post. Cool.

Thanks for the post.Really thank you! Great.

I truly appreciate this article. Fantastic.

Thanks for the blog. Will read on…

Very informative blog post.Really thank you! Much obliged.

I really like and appreciate your blog post.Much thanks again. Will read on…

Hey, thanks for the blog post.Really thank you! Really Cool.

Fantastic post.Thanks Again. Really Cool.

Great, thanks for sharing this post.Really thank you! Want more.

Really informative article.Really looking forward to read more. Will read on…

Appreciate you sharing, great blog post.Really thank you!

Say, you got a nice blog. Will read on…

Thanks for the article. Fantastic.

Thank you for your article post.Really thank you! Cool.

Thank you for your article post.Really looking forward to read more. Great.

Really appreciate you sharing this post.Really looking forward to read more.

Thanks a lot for the post. Really Great.

Wow, great post.Thanks Again. Awesome.

I appreciate you sharing this blog article.Thanks Again. Want more.

I am so grateful for your article post.Thanks Again. Awesome.

Thanks a lot for the post.Much thanks again. Fantastic.

Im thankful for the blog article.Much thanks again. Really Great.

I loved your blog article.Really looking forward to read more. Fantastic.

I truly appreciate this blog.Much thanks again. Awesome.

Thanks again for the article post.Much thanks again. Really Great.

I appreciate you sharing this article post.Really looking forward to read more. Cool.

Appreciate you sharing, great post. Keep writing.

Looking forward to reading more. Great article.Thanks Again. Keep writing.

I really enjoy the blog.Really thank you! Will read on…

Great, thanks for sharing this article. Keep writing.

Wow, great blog post. Really Great.

I really enjoy the blog article.Really looking forward to read more. Keep writing.

Very informative blog article.Really thank you!

Very informative blog.Thanks Again. Really Cool.

Hey, thanks for the blog post.Really looking forward to read more. Really Cool.

I appreciate you sharing this article post.Really looking forward to read more. Will read on…

Thanks

Awesome blog post.Much thanks again. Much obliged.

Great, thanks for sharing this article post.Thanks Again. Really Cool.

Thanks so much for the article post.Thanks Again. Awesome.

I really like and appreciate your article. Will read on…

wow, awesome article.Thanks Again. Cool.

I really enjoy the post.

Awesome blog article.Much thanks again. Really Cool.

Thanks

Thanks again for the article. Want more.

Thank you ever so for you blog.Really thank you! Fantastic.

I think this is a real great blog post.Thanks Again. Cool.

Awesome article post.Really thank you! Want more.

Very informative post.Really thank you! Fantastic.

I truly appreciate this article.Really looking forward to read more. Will read on…

Really informative blog.Really thank you! Keep writing.

I appreciate you sharing this blog. Will read on…

Great article. Really Great.

I really like and appreciate your article post.Really thank you! Really Great.

I really enjoy the blog article.Really looking forward to read more. Fantastic.

Very good blog. Keep writing.

Hey, thanks for the blog post.Much thanks again.

Very informative blog article.Much thanks again. Want more.

Really informative post.Really thank you!

Hey, thanks for the blog article. Great.

Enjoyed every bit of your article.Really thank you! Much obliged.

I truly appreciate this blog. Want more.

Thank you ever so for you article post.Much thanks again. Much obliged.

Im thankful for the blog article.Really thank you! Much obliged.

Im thankful for the blog. Great.

Very good blog article.Really thank you! Keep writing.

Very good blog.Really thank you! Really Great.

I really liked your article.Really looking forward to read more. Awesome.

I loved your article post. Will read on…

Really enjoyed this blog article.Really thank you!

Thanks again for the blog post.Really thank you! Will read on…

I really enjoy the blog post.Really thank you! Want more.

Really informative article post.Much thanks again. Much obliged.

Fantastic article.Really thank you! Keep writing.

Thanks a lot for the blog.Really looking forward to read more. Keep writing.

Very informative blog article.Really thank you! Much obliged.

Thank you ever so for you blog.Really looking forward to read more. Awesome.

I really like and appreciate your article post.Thanks Again. Really Cool.

I value the blog article.Really looking forward to read more. Fantastic.

Thanks a lot for the blog post. Keep writing.

I loved your blog post.Much thanks again. Will read on…

Very good article post.Really looking forward to read more. Fantastic.

Thanks a lot for the blog.Really looking forward to read more. Awesome.