Source of natural fiber with classification is described in this article. The textile industry uses many different kinds of fibers as its raw materials. Some of these fibers were known from earlier civilizations and in modern times. Other fibers have acquired varied degrees of importance in recent years. The factors influencing the development and utilization of all these fibers include:

- Their ability to be spun.

- Their availability is in sufficient quantity.

- The cost or economy of production.

- The desirability of their properties to consumers.

Mainly there are two types of textile fiber. Such as:

- Natural fiber.

- Man-made fiber.

Source of Natural Fiber

Natural fibers that occur in nature can be classified as vegetable fibers, animal, and minerals. Vegetable fibers, found in the cell walls of plants, are cellulosic compositions. Animal fibers, produced by animals or insects, are proteins in their composition. The mineral fiber asbestos is mined from certain types of rock. In this article, I will discuss the source and different types of natural fiber. Natural fibers are three types. Such as:

- Vegetable fibers

- Animal fibers

- Mineral fiber

1. Vegetable Fiber

The source of vegetables is a different plant or parts of the tree. Vegetable fiber are also called cellulosic fibers. However, in this article, I briefly discuss some important vegetable fibers:

1.1 Cotton

The word cotton comes from the Arabic word “Katan.” It is called the king of fibers. Cotton is also the backbone of the world’s textile market. The cotton fiber grows in the seedpod, or boll, of the cotton plant. Each fiber is a single elongated cell that is flat, twisted, and ribbon-like with a wide inner hollow. It comprises about 90% cellulose and 6% moisture; the remainder consists of natural impurities. The outer surface of the fiber is covered with a protective wax-like coating, which gives the fiber a somewhat adhesive quality. Cotton is called universal fiber because this fiber is used for all types of apparel, home furnishing, and industrial application.

1.2 Jute

Jute is another vegetable and cellulosic fiber. Just fiber, also called bast fiber. Bast fibers come from the plant’s stem, near the outer edge. As jute fiber is collected from the bast of a plant, hence jute fiber is called bast fiber. Jute is a lingo cellulosic fiber that also contains about 55-65% cellulose,14- 20% hemicellulose, 12-13% lignin, 13% moisture content, 0.2% pectin, 0.5% wax. Jute is used to manufacture different types of traditional packaging fabrics, hessian, sacking, carpet backing, mats, bags, tarpaulins, ropes, and twins. Jute fibers also are used in a wide range of diversified products: decorative fabrics, chic saris, salwar kamizes, soft luggage, footwear, greeting card, molded door panels, and other innumerable useful consumer products. Recently polyethylene has been produced from jute.

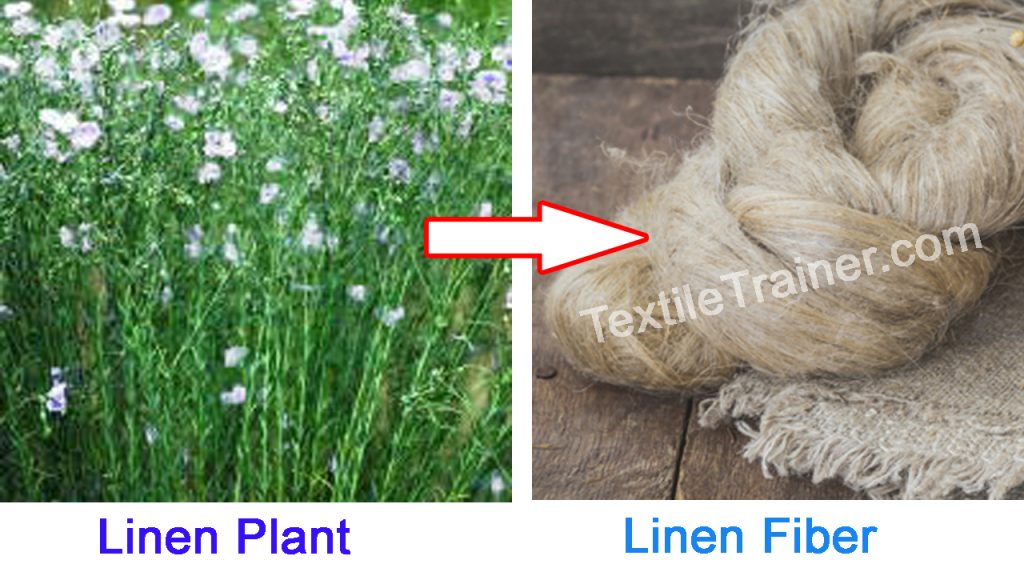

1.3 Linen

The linen fiber is obtained from the stalk of the flax plant. The word flax is derived from the old English “Flex.” The other common names of flax are lan, lein, linen, liner, line, llion, and linum. The hair-like fibers, which are held together by a gummy substance called pectin, comprise the core of the flax stalk. Like cotton, linen is also a cellulosic natural fiber and contains 75% cellulose, 5% hemicelluloses, pectin, aromatics, 4% lignin, 3% fat/wax, 0.5% ash, and 12.5% water. Line fiber is relatively smooth, straight, and lustrous. Linen fiber is more brittle and less flexible than cotton. It is more challenging to prepare and spin into yarn. Linen yarn can be very strong and lustrous and is used for apparel, home furnishing, and upholstery.

1.4 Ramie

Ramie is also known as a rhea, grass cloth, China grass, and Army/Navy cloth. It has been used for several thousand years in China. The ramie plant is a tall perennial shrub from the nettle family that requires a hot, humid climate. Ramie is fast-growing and can be harvested as frequently as every 60 days. It is white with a silky luster, similar to flax in absorbency and density but coarser. One of the strongest natural fibers. It has low elasticity and dyes easily. strands of ramie range from 190 cm in length, with individual cells as long as 40 cm. Ramie is used in many imported apparel items, including sweaters, shirts, blouses, and suits. Ramie is important in furnishings for window treatments, pillows, and table linens.

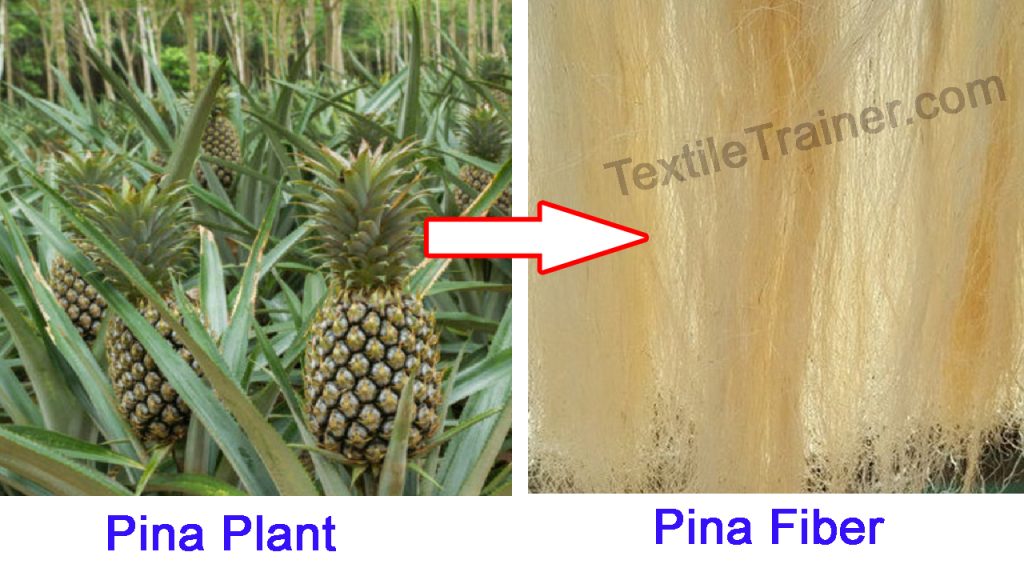

1.5 Pina

Pina is obtained from the leaves of the pineapple plants. The fiber is soft, lustrous, and white or ivory. Since pina is highly susceptible to acids and enzymes, rinse out acid stains immediately and avoid detergents or enzyme presoaks. The fiber length is up to 1 m with a diameter of 200 to 400 microns. It is coarser fiber and unsuitable for textiles or fabrics. But it is strong, durable, stretchable, and doesn’t absorb moisture easily. Sisal is used to replace glass fibers in composite materials used to make cars and furniture.

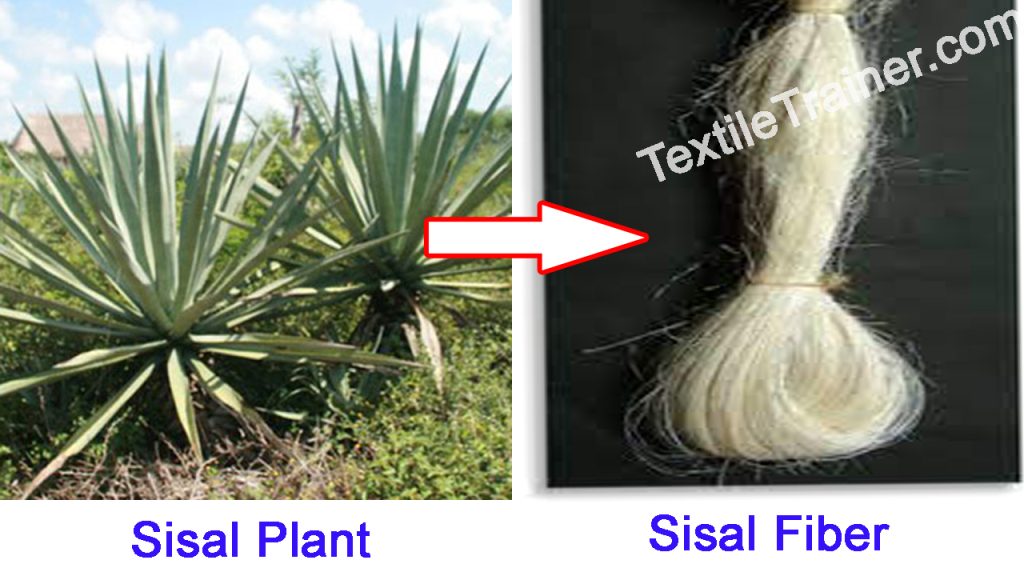

1.6 Sisal

Sisal is grown in West Indies, Central America, and Africa. Sisal is smooth, straight, and yellow. They are used for better grades of rope, twine, and brush bristles. Sisal is used for upholstery carpets and custom rugs that can be hand painted for a custom look. Sisal provides a complementary texture and black ground for many furnishing styles.

1.7 Abaca

Abaca is obtained from a member of the banana tree family. Abaca fibers are coarse and very long. Length of abaca fiber up to 15 feet. The color of abaca fiber is off-white to brown. The fiber is strong, durable, and flexible. It is used for ropes, cordage, floor mats, and table linens.

2. Animal fiber

There are several animal fibers, each obtained from a different source. But only two are recognized as significant textile fibers. They are wool and silk. Other animal fibers are Qiviut, Angora, Camel’s Hair, Cashmere, etc.

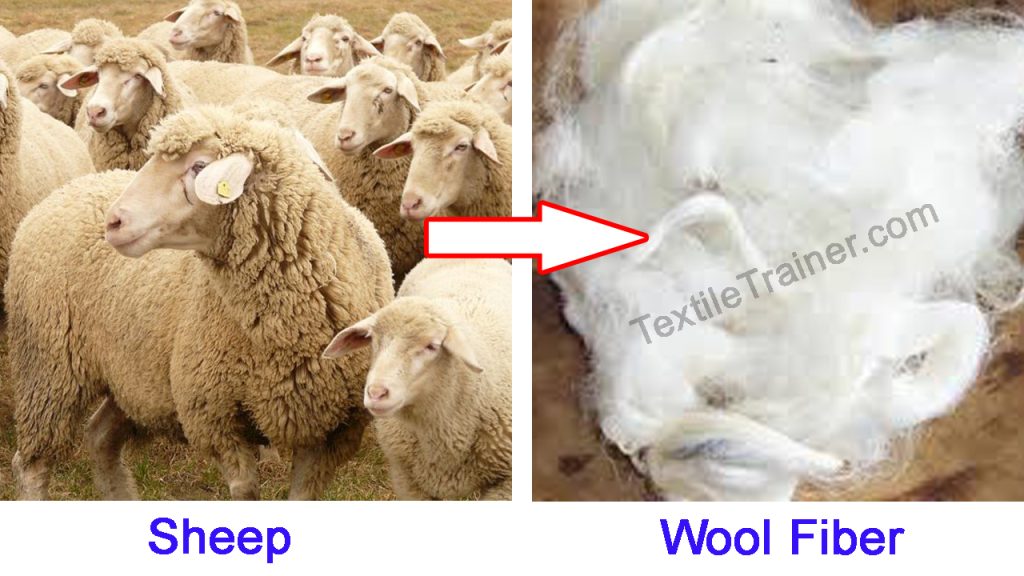

2.1 Wool

Wool is the natural, highly crimped textile fiber obtained from various sheep. Wool is the oldest fiber known to humans. It was the first fiber to be spun into yarn and fabric. Wool is mainly a protein fiber but also has some other components. Other components of wool fiber are 33% keratin, 28% suint, 26% Dirt, 12% fat, and 1% mineral matter. The main component of wool is Keratin. The keratin of wool fiber contains 50% Carbon, 12% Hydrogen, 10% Oxygen, 25% Nitrogen, and 3% Sulphur. Wool is a relatively coarse fiber. It is crimpy and has scales on its surface. Depending upon the breed of sleep, the appearance of wool varies, with some having a great deal of crimp and smaller, finer scales to those having little crimp and coarser scales. Two striking characteristics of wool fiber are its susceptibility to heat and felting properties caused by the surface scales.

2.2 Silk

Silk is a continuous protein, only one natural filament made by the silkworm, produced by caterpillars belonging to the genus Bombyx. Silk is a natural protein fiber. It is similar to wool in that it is composed of amino acids arranged in a polypeptide chain but has no cross-links. Silk is mainly a protein fiber, whose main element is fibrous, but a gummy substance, sericine present outside of fibron. Silk fibers consist of 72-81% fibroin, 19-28% sericin, 11% water, 1.5% salts, 0.8-1.0% fat and wax, 1.0-1.4% coloring matter, and ash. The silk fiber is relatively lustrous, smooth, lightweight, strong, and elastic. Historically, it has always been a highly desired fiber used for apparel, home furnishing, and upholstery. Its desirability is one of the factors that prompted the production of man-made fibers to simulate silk.

2.3 Qiviut

Qiviut, a rare and luxurious fiber, is under the wool of the domesticated musk OX. A large musk ox provides about 6 pounds of wool each year. The fiber can be used just as it comes from animals, for it is protected from debris by the long guard hairs and has a low lanoline content. Qiviut resembles cashmere in hand texture but is much warmer. The fleece is not shorn but is shed naturally and is removed from the guard hairs as soon as it becomes visible.

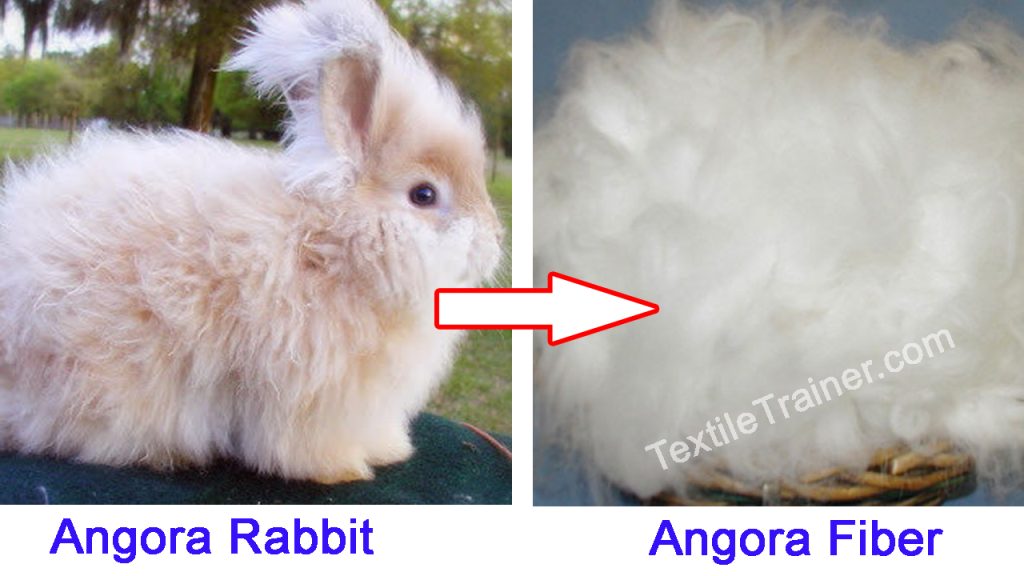

2.4 Angora

Angora is the hair of the Angora rabbit produced in Europe, Chile, and the United States. It is harvested up to four times a year by plucking or shearing. Fiber yield and quality vary with the rabbit and its health and breed and ranges from 8 to 30 oz. this fiber is very fine fluffy, soft, slippery, and fairly long. Angora doesn’t take dye well and usually has a lighter color than other fibers with which it is blended. Rabbit hair is often used to make felt for hats, but it is too short of making into yarns for woven or knit fabrics.

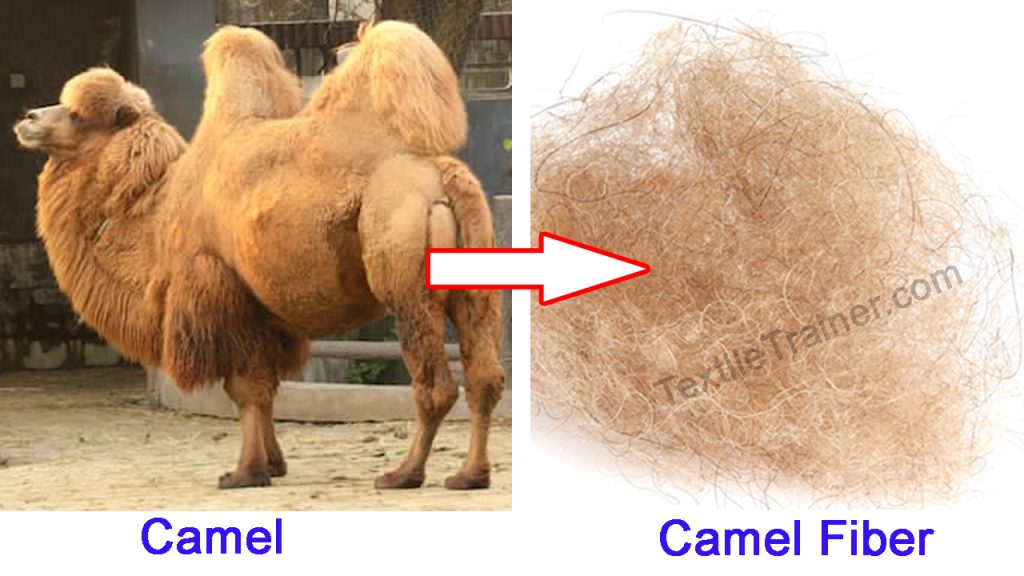

2.5 Camel’s hair

Camel’s hair is obtained from the two-humped Bactrian camel, found from Turkey east to china and north to Siberia. Camel’s hair is an excellent insulator. The hair is collected as it is shed or sheared from the animals. Camel’s hair gives warmth without weight; the finer fibers are valued for apparel. They are often used in blends with sheep’s wool dyed the tan color of camel’s hair. Camel’s hair is used in coats or jackets, scarves, and sweaters. Blankets of camel’s hair and wool are also available.

3. Mineral fiber

Mineral fiber that obtain from inorganic natural source. Mineral fibers are less important in the textile field.

3.1 Asbestos

Asbestos is the name given to several natural minerals which occur in a fibrous crystalline form. The asbestos is initially crushed to open up the fiber mass, followed by carding and spinning to yield fibers of circular cross-section 1-30 cm in length. Asbestos is very good and resistant to heat and burning, acids and alkalies, and other chemicals. Although it has low strength, asbestos fiber does not deteriorate in everyday usage, and insects or microorganisms do not attack it. Asbestos is used in fireproof clothing, conveyor belts, brake linings, gaskets, industrial packing, electrical windings, insulations, and sound proofing materials.

References

1.Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L.B graphics and Printing.

2.Corbman, B. P. (1983). Textiles Fiber to Fabric. New York: Mc Graw Hill.

3.Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

4.Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

Thanks for the tips you are giving on this website. Another thing I want to say is always that getting hold of some copies of your credit rating in order to check accuracy of each detail would be the first activity you have to perform in fixing credit. You are looking to thoroughly clean your credit profile from harmful details mistakes that screw up your credit score.

Heya i am for the primary time here. I came across this board and I find It truly useful & it helped me out a lot. I am hoping to present something back and aid others like you helped me.

thanks for your comments.

I do agree with all of the ideas you have presented in your post. They’re very convincing and will certainly work. Still, the posts are too short for beginners. Could you please extend them a little from next time? Thanks for the post.

ok. I will try.

I have learn some excellent stuff here. Certainly worth bookmarking for revisiting. I wonder how so much effort you set to make the sort of magnificent informative web site.

thanks for bookmark my site.

This actually answered my downside, thank you!

thanks too. please support us.

Really appreciate you sharing this article.Thanks Again. Fantastic.