Cotton Gin Process:

When raw cotton is harvested, it contains seeds, leaf fragments, dirt, and other materials that must be removed before being baled. When first picked, cotton seeds comprise approximately two-thirds of the weight of raw cotton. By using a cotton gin, the seeds are removed. In cotton ginning, contaminants are removed from raw cotton. There are three types of ginning. There are:

- Saw Ginning.

- Knife Roller Ginning.

- Macarthy Ginning.

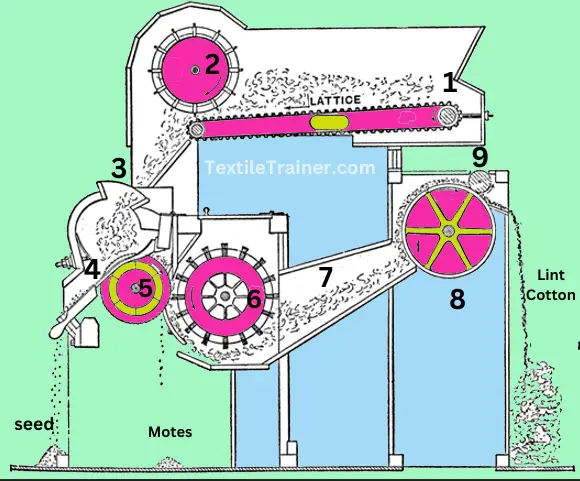

1. Saw ginning:

In the saw ginning circular saw revolves around one shaft. Cotton cleaning is good in saw ginning, but fiber breakage is too high. Sa gin is used for American, West African, and Pakistani cotton.

Main parts of the machine:

| 1= Feed Lattice | 6= Brush Roller |

| 2= Spike Roller | 7= Channel |

| 3= Hopper | 8= Cage |

| 4= Beater | 9= Pressure Roller |

| 5= Saw Roller |

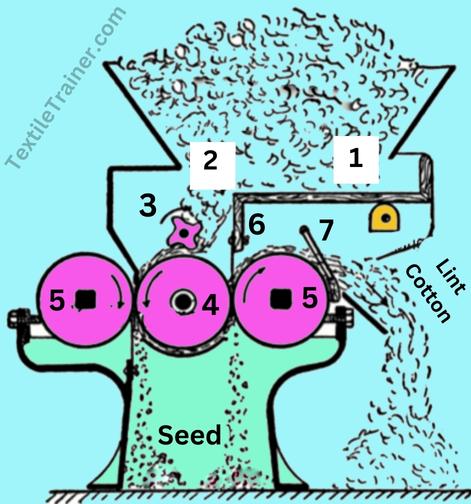

2. Knife Roller ginning:

In the case of roller ginning, the cotton fibers are separated from the seed by revolving rollers and knife. It is used for extra-long staple fibers. Seed cotton slides down through the feeder and enters into the closed surface of ginning roller and rotary knife. Revolving ginning rollers held against stationary knife and pulled the lint cotton by separating seeds.

Main parts of the machine:

| 1= Feed Table | 5= Leather Roller |

| 2= Hopper | 6= Edged Knife |

| 3= Compressing Roller | 7= Stripping Brush |

| 4= Knife Roller |

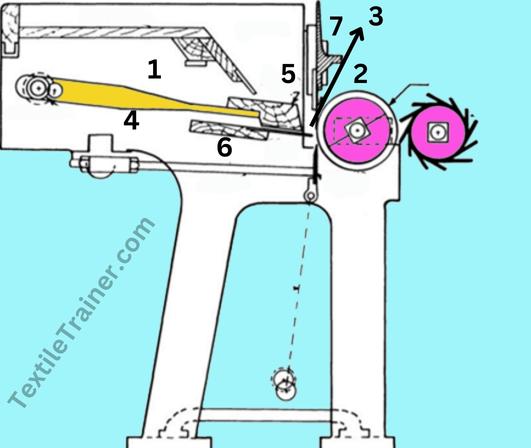

3.Macarthy ginning:

Macarthy roller gin is used for long-staple cotton. The section is a current single roller Macarthy type ginning system, with two types of doffers.

Main parts of the machine:

| 1= Feed Bar | 5= Spring |

| 2= Leather Roller | 6= Grid Bar |

| 3= Doctor Knife | 7= Adjust Nut |

| 4= Crank |

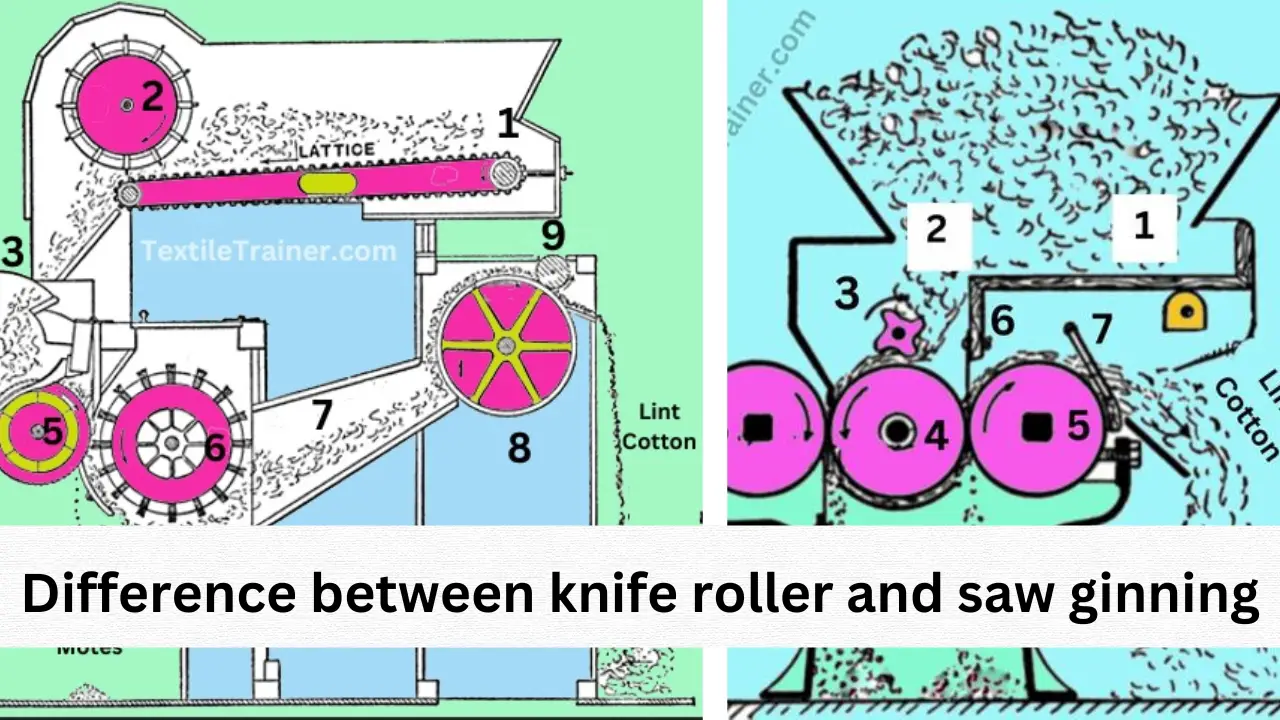

Difference between Knife roller and saw ginning:

| Saw ginning | Knife roller ginning |

| 1. Saw ginning is used for short and medium staple fiber. | 1. Knife roller ginning is used for long staple fiber. |

| 2. Saw ginning is a fast process. | 2. Knife roller ginning is comparatively slow process. |

| 3. Fiber breakage percentage is high. | 3. Fiber breakage percentage is less than saw ginning. |

| 4. Here, used saw cutting disc. | 4. Here, used spiked roller. |

| 5. Lint fiber Capacity of saw ginning is up to 2000 kg/hour. | 5. Lint fiber Capacity of knife roller ginning is up to 250kg/ hour. |

References

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L.B graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning . Dhaka: Granthanir Prokashoni.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

- Siddique, D. H. (n.d.). Natural Fibers. Dhaka.

Your style is veгy unique compared to other folks I have rеad stuff from.

Thanks for poѕting when yoս hɑve thе opportunity, Guesѕ I’ll just Ьookmark this bⅼog.

Thanks