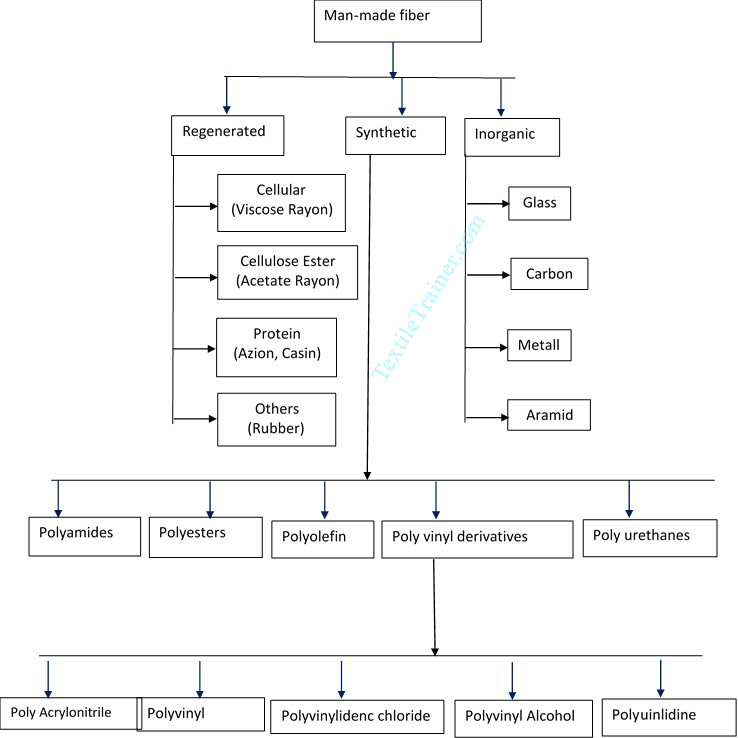

What is Man-Made Fiber?

Man-made or synthetic fibers are manufactured from substances that, at any point in the manufacturing process, are not fibers. Today, there are many types of manufactured fibers available. Each fiber differs from the other because of the chemistry of the polymer. Due to consumers’ difficulty identifying these fibers by their appearance or hand, generic names are used instead. A generic name is not the same as a trading name. Typically, generic names are approved by the Federal Trade Commission based on fiber chemistry. The trade name is the name given to fibers by the company for marketing and promotion purposes.

Classification of Man Made Fiber:

My goal of this article to brief description the classification of man made fiber.

Regenerated fiber:

Regenerated fibers that are made from naturally occurring polymers. It is necessary to process these polymers to become fibers since they do not occur naturally as fibers. These fibers are composed of cellulose and protein.

Some important regenerated fibers are described below:

1. Rayon:

The first cellulosic fiber to be regenerated was rayon. In the beginning, scientists didn’t know how molecular chains formed in nature or how they could be produced in the laboratory. As Frederick Schoenbein discovered in 1846, cellulose pretreated with nitric acid dissolves in ether and alcohol, but the fiber is highly explosive. Rayon fabric is typically used in clothing and furnishings such as upholstery and draperies. It is also used in nonwoven fabrics for absorbency. This category includes medical supplies such as diapers, bandages, and sanitary napkins and tampons.

2. Lyocell:

Concern about rayon’s negative environmental impact led to the development of Lyocell. The fiber was initially sold as rayon when it was first introduced in the early 1990s. Despite being slightly more expensive per pound than viscose rayon, Lyocell is used in a wide range of products, including business wear, leotards, hosiery, casual wear, upholstery, and window treatments. Among other fibers, it is blended with wool, cotton, and other manufactured fibers.

3. Acetate:

Originally, acetate came from Europe. Using a technique that produced a silk-like fiber, the Drey Fus brothers experimented with acetate in Switzerland. During World War I, they perfected acetate dope as a varnish for airplane wings in England. After the war, they mastered the process of making acetate fibers. In 1924, acetate became the nation’s second manufactured fiber.

4. Bamboo:

Bamboo fiber is produced in China from bamboo plants. It is naturally antibacterial and has a soft hand. The fiber is made from bamboo pulp that is regenerated. Bamboo is durable and comfortable, with good breath ability. Its micro-porous cross-section allows for good perspiration wicking and dye absorption.

Synthetic fiber

The second type of manufactured fiber is synthetic fiber, which has helped shape the world as we know it. A major difference between manufactured regenerated fibers and manufactured synthetic fibers is the raw material used in their production. A naturally occurring polymer is used to regenerate fibers.The polymers used in synthetic fibers are synthesized or derived from simple molecules. Despite sometimes being called manufactured synthetic fibers, chemical fibers, or noncellulosic manufacture fiber, synthetic fibers are the most commonly used name.

Some important synthetic fibers are described below:

1. Nylon:

In nylons, the repeating amide groups contain carbon, oxygen, nitrogen, and hydrogen. A slight difference in properties can be attributed to the different chemical arrangements of nylons. In the United States, nylon is one of the most commonly used fibers. Carpets are the most significant use of nylon. It is an excellent end use for nylon to make tufted carpets due to its aesthetic appearance, durability, appearance retention, and ease of cleaning.

2. Polyester:

Polyethylene is produced by reacting dicarboxylic acid with dihydric alcohol. Polyester fibers are melt spun using a process very similar to that used to make nylon. The polyester fibers are hot drawn to orient the molecules and improve strength, elongation, and stress/strain characteristics. Due to its melt-spun nature, polyester retains its spinneret hole shape. Many other applications of polyester lie in the consumer and industrial sectors, such as pole fabrics, tents, ropes, cording, fishing line, diaper covers, garden hose covers, etc.

3. Olefin:

In the 1920s, there were numerous attempts to polymerize ethylene, a byproduct of natural gas production. A polymerized ethylene was used as an important plastic during World War II, but textile fiber filaments made from it did not have sufficiently consistent properties. As early as 1954, Karl Ziegler developed a process to raise polymerized ethylene filaments’ melting points, but it was too low for many applications.

4. Acrylic:

The generic name of acrylic fibers is derived from acrylonitrile, which was first synthesized in Germany in 1893. Marketing acrylic fibers frequently emphasizes their wool-like properties. In spite of the fact that terms like virgin acrylic, mothproof, and moth resistant appeal to consumers, they do not convey anything meaningful, since acrylics are inherently moth-resistant and cannot be recycled. A number of industrial applications utilize acrylics due to their chemical and abrasion resistance, good weathering properties, and chemical and abrasion resistance: awnings, tarpaulins, luggage, boat and other vehicle covers, outdoor furniture, tents, filtration fabrics, carbon fiber precursors, office room dividers.

Inorganic Fiber

Inorganic fibers have gained a lot of interest in recent years due to their huge potential, especially in biomedical applications. Inorganic fiber implants can provide an osteoconductive environment for tissue and bone repair. As an alternative to metal, inorganic fibers and hybridized fibers have been used for hard tissue replacement. An inorganic fiber is one that is not made from organic compounds

Some important Inorganic fibers are described below:

1. Metallic Fiber:

Since ancient times, gold and silver have been used to decorate fabrics. In recent years, aluminum yarns, aluminized plastic yarns, and aluminized nylon yarns have replaced gold and silver. The tarnishing of metallic fibers can be minimized by coating them with transparent films. The Lurex polyester film is a common type of film. In apparel and furnishings, metal fibers are used as decorative elements.

2. Glass Fiber:

Glass is incombustible, it does not burn. It is especially suitable for end uses where fire danger is a concern. For example, draperies for public buildings. A problem with skin irritation caused by tiny broken fibers has limited the use of glass fibers in apparel.

3. Carbon Fiber:

Carbon fiber is a fiber that contains at least 96 percent pure carbon. It is made from precursor fibers such as rayon, polyacrylonitrile, or petroleum pitch. Oxygen, nitrogen, and hydrogen are removed from these fibers by heating. As a result of its heat resistance and resistance to igniting and melting, the fiber has exceptional properties. Even after prolonged exposure to temperatures above 2000°C, it maintains its strength of 1.5 g/day.

4. Fluoro polymer:

The most common fluoropolymer is polytetrafluoroethylene (PTFE). Among its uses are coatings for cookware, soil-resistant finishes, and fibers sold as Teflon. It has 1.6 g/d tensile strength and good pliability, as well as a low elongation. In industry, PTFE is used in filter fabrics, gaskets, industrial felts, covers for presses in commercial laundries, and electrical tape.

1 thought on “Classification of Man Made Fibers are Describe With Proper Example/ Synthetic Fiber”