Experiment Name:

Lab Report: Study on material passage diagram of slip draft in jute spinning./Study on slip draft jute spinning.

Introduction:

The essential features of the spinning process are drafting, twisting and winding on. Jute spinning frames have two sets of rollers extending along the entire length of the machine – retaining rollers and drawing rollers. There are two parts of each set: a positively driven member and a pressing member, which are gripped by fibers. The draft works as usual by attenuating the material and reducing its weight. Typically, the frame’s reach is slightly longer than the longest fibers in the material. The breast plate is located between the retaining roller and drawing roller. In order to control short fiber movement properly, this plate projects slightly forward from the line connecting the two sets of rollers in order to play its proper role. Identifying where the sliver will begin drafting is the purpose of the breast plate. A slight tension develops in the sliver as a result of its position, which presses the material on to the plate more firmly. As inter-fiber movement occurs at the point subjected to the greatest tension below the plate, it is here that drafting occurs, as the tension below the plate is greater than that above the plate. In this experiment, we will learned working principle of jute slip drafting system.

Objectives:

- To know about slip draft in jute spinning.

- Come to learn material passage diagram of slip draft.

- To know working principle of slip draft in jute spinning.

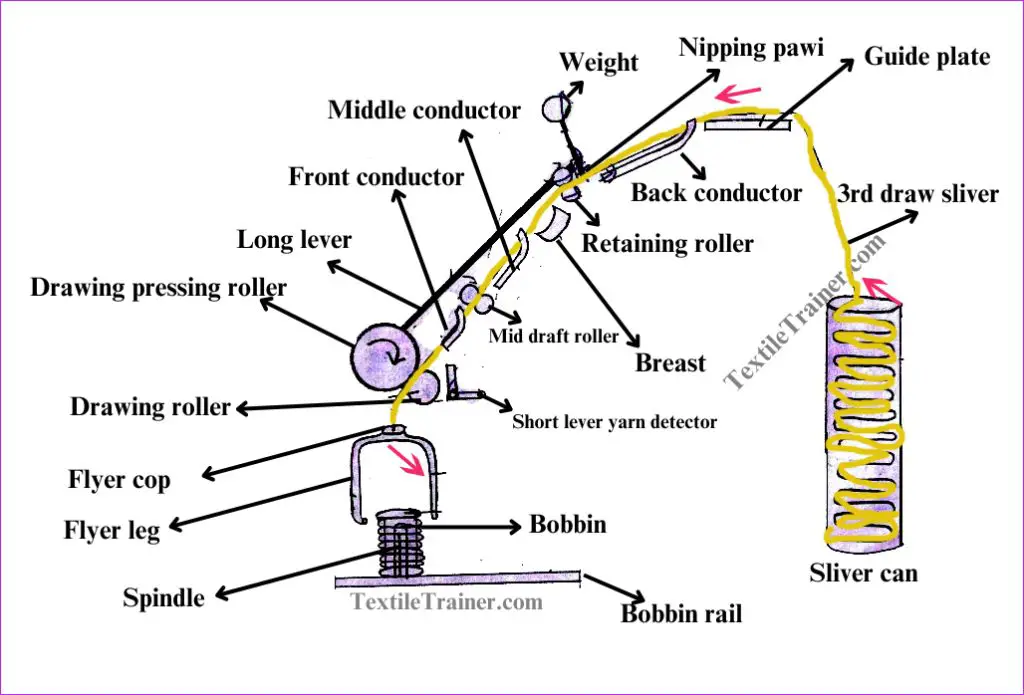

Material Passage Diagram of Slip Draft:

Material passage diagram of slip draft in jute spinning is given below:

Working Principle:

A crimped sliver from the finishing drawing is fed into the spinning frame from the back. This sliver enters the spinning frame through a sliver guide behind the drafting zone. It is passed through an inverted breastplate by the conductor and then enters the nip of a drawing and pressing roller. Usually, the original draft is placed between the conductor and the drawing roller after passing through the underside of the inverted breastplate. Upon touching the draft lightweight sliver yarn detector, the delivered sliver is twisted into yarn, which enters the flyer’s hole, which in turn enters the flyer bobbin through the flyer leg’s eye. In this process, the bobbin is placed on a carrier that rotates with the bobbin in the tension of the yarn as the flyer rotates at its own pace and delivers the sliver as a drawing roller yarn. The machine is stopped when the bobbin is full, the yarn bobbin is doffing , and the machine is restarted by reinserting the empty bobbin for the next production.

Conclusion:

In this experiment, we learned about slip draft in jute spinning. The working principle of slip draft was also explained. We are thankful for the help of our teacher. This experiment will be helpful in our future careers.

You may read:

- Jute First Drawing Frame: Easy Material Passage Diagram.

- Jute 2nd Drawing Frame: Material Passage Diagram Easy Way.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

2 thoughts on “Slip Draft in Jute Spinning: Simple Material Passage Diagram/ Lab Report-08”