Experiment Name:

Lab Report: Study on material passage diagram of apron draft jute spinning frame./ Study on working principle of jute apron draft spinning.

Introduction:

Fibers are drafted in the drafting zone with rubber aprons, thus the name apron draft. Mackie’s latest contribution to the jute industry is the Apron Draft Spinning Frame Machine. Mackie manufactures jute machinery in Ireland and England. A long period of research and development was needed to perfect the drafting apparatus for jute fiber. Mackie’s deserves appreciation for such a suitable and ideal spinning frame that had gradually replaced all previous models in course of time. It set a new standard for efficiency, productivity, and design in modern jute spinning.

Objectives:

- To know about apron draft jute spinning frame.

- Come to learn diagram of jute apron draft spinning frame.

- To know working principle of apron draft jute spinning frame.

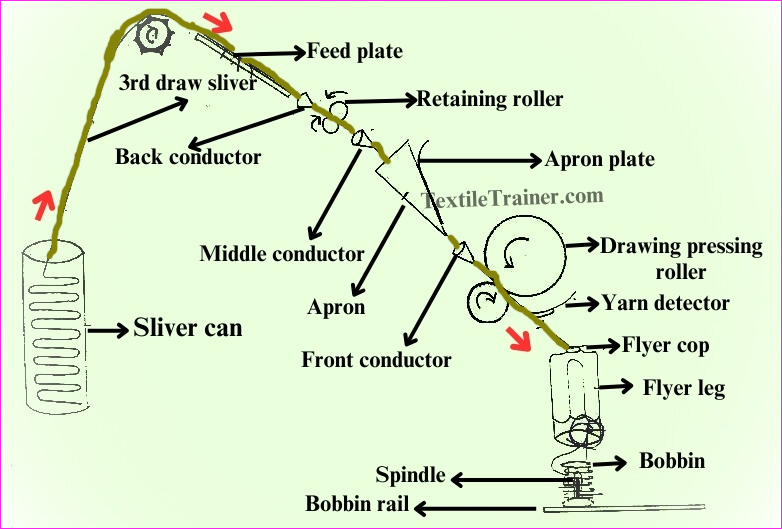

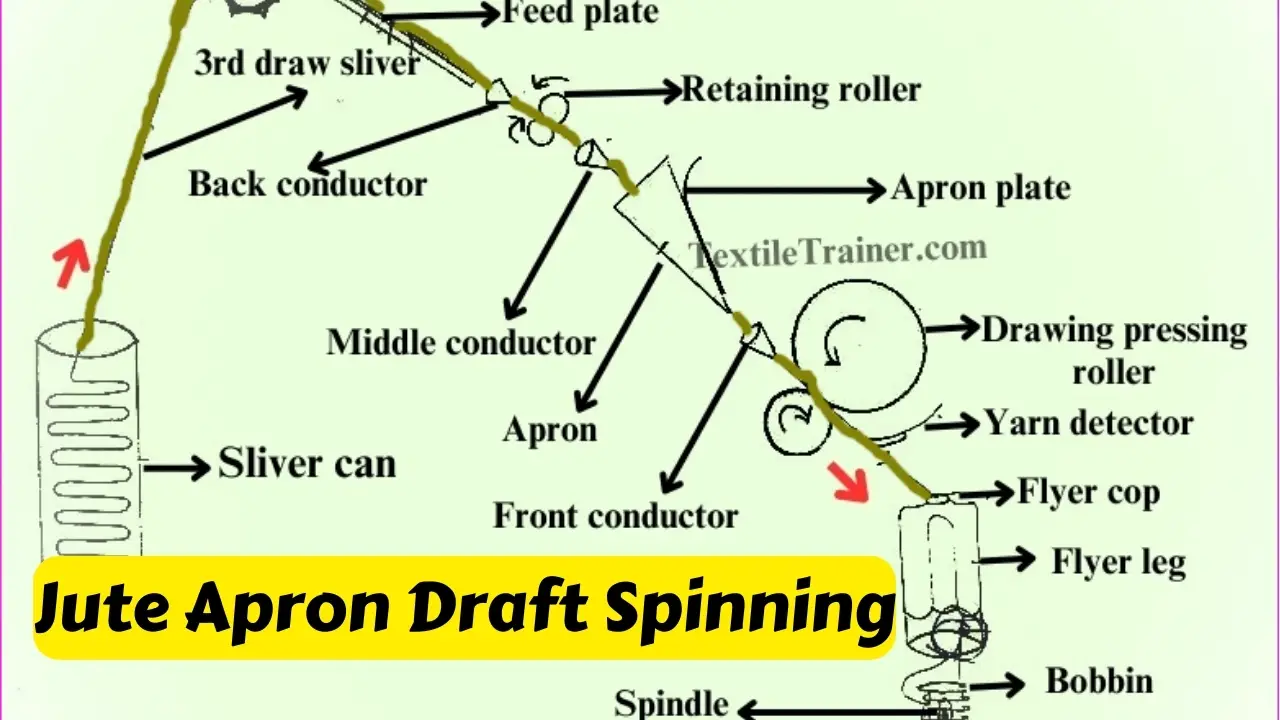

Diagram of Apron Draft Spinning Frame:

Working Principle of Apron Draft Jute Spinning:

From the back of the spinning frame, crimped sliver is fed from the finisher drawing. After entering the spinning frame’s drafting zone, the sliver is then pressed into the front pair of aprons by the retaining and pressing roller. As a result, the original drafting of the sliver is organized here. Because aprons can easily control all fibers. As a result, the production of high-quality yarn from low-quality jute can only be achieved by using an apron draft frame. All fibers are controlled by the apron and sent to the drawing roller. Deliveries are made by touching the draft lightweight sliver with help of yarn detector. The sliver is then twisted and turned into yarn. As the flyer spins at its own speed, the bobbin yarn tension is set on the bobbin carrier. The difference in circumference between the flyer and the bobbin creates yarn on the button. When the bobbin yarn is full, then the machine is turned off and the full bobbin is removed. Finally the machine is restarted again with an empty bobbin.

Conclusion:

During this experiment, we learned about the apron draft jute spinning frame. We also learned the working principle of the apron draft jute spinning frame. Thanks to our teacher for helping us.

You may read:

- Jute First Drawing Frame: Easy Material Passage Diagram.

- Jute 2nd Drawing Frame: Material Passage Diagram Easy Way.

- Slip Draft in Jute Spinning: Simple Material Passage Diagram.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

1 thought on “Apron Draft Jute Spinning Frame with Easy Diagram/ Lab Report-09”