Introduction

Fabric has traditionally been joined by sewing. There are, however, a number of alternative methods that are becoming increasingly popular over the past few years. Compared to sewing, these alternative methods offer a number of advantages, including greater speed and efficiency, reduced labor costs, improved seam strength and durability, better appearance, and greater flexibility in design when compared to traditional sewing methods. Fabric Joining such is the crucial part of garments industry.

Throughout this article, we will look at four of the most common alternative methods of joining fabrics: fusing, welding, adhesives, and molding. We will take a closer look at each of these methods. The advantages and disadvantages of each method will be discussed, along with how each method can be used to create different effects based on which method we choose.

Alternative methods of fabric joining include:

1. Fusing

2. Welding

3. Adhesives

4. Molding

Fusing

The most common method of joining fabrics is to fuse them together. The sewn interlining process has been completely replaced by the fusing process, in which the resin or polymer coated interlining is placed beneath the main fabric. In order to join them properly, heat and pressure are applied. The resin melts when heat is applied, and then pressure is applied to adhere to the main fabric (stick). In the fusing process, only interlining fabric is joined to a main fabric after joining the resin materials. Once the resin materials become hard, they bind the interlining fabric strongly to the main fabric.

Fusing is the process of joining two pieces of fabric using heat and pressure. Heat and pressure are applied to melt the adhesive on the fusible interlining after the interlining is placed between the two pieces of fabric. As a result, the adhesive bonds the two pieces of fabric together. Interlinings are often attached to garments by fusing, which is a quick and easy method of joining fabric.

Welding

As part of garment manufacturing, welding is used to seal together thermoplastic materials without using external heat. Welding has limited uses but is very important where it is used.

1. The welding of decorative motifs onto garments.

2. Closure of the cutting edges of fabric cut for garment making

3. Temporarily joins some garment parts that will be permanently joined later by top stitching.

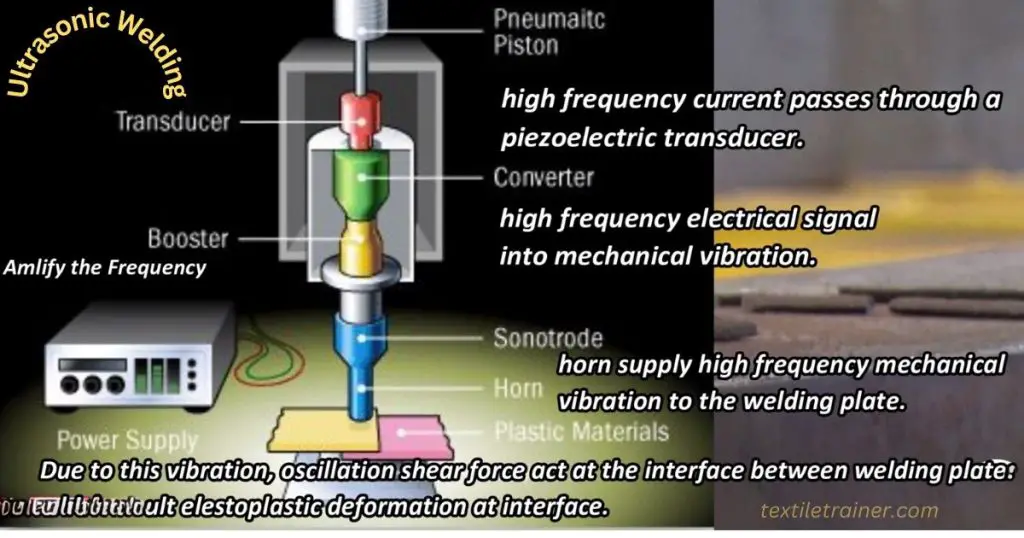

If two hard materials vibrate against each other, they become hot at the point of contact. Welding materials must contain at least 65% thermoplastic fibers. Placing thermoplastic materials between the vibration points will generate heat within the materials where they touch and will apply in sufficient heat at temperatures between 110 and 170°C.

By using high-frequency or ultrasonic vibrations, fabric welding creates a molecular bond between thermoplastic materials. The method is particularly popular in industries requiring airtight or watertight seams, such as outdoor gear and inflatable structures. Pressure and heat are applied to the fabric layers between two electrodes. As a result, the bond is strong and resistant to wear and tear.

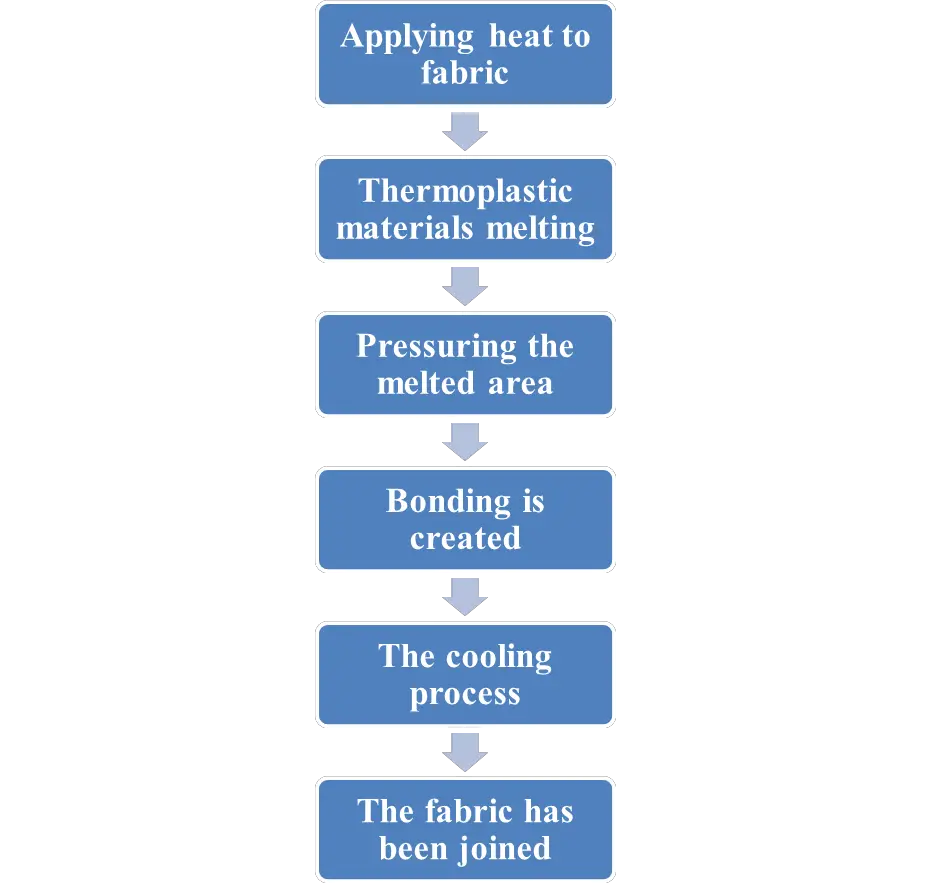

Welding involves the following steps:

Adhesive

There are two types of adhesives:

1. A coating of thin adhesive film on silicon paper which when transferred to fabric, the plies of fabrics becomes joined.

2. A type of material which melts when heated, allowing fabric plies to be joined.

The second type of adhesive differs from welding in that heat is generated within the materials during welding. In fabrics containing less than 65% thermoplastic materials, adhesive is used instead of welding.

Uses:

- In edge neatening of hems, adhesive thread is used as one of the looper threads. By pressing the hem, the thread melts and holds it in place without sewing.

- Waterproof garment seams

Molding

Due to its inability to join a number of plies of fabric, moulding is not an accurate and entirely used fabric joining method. Nevertheless, it is called an alternative method of fabric joining because it allows us to give a definite shape to the garment without creating seams. Fabrics with less than 65% thermoplastic fibres can be joined through molding. Knitted fabrics are used here because they can easily be stretched or shrunk. Fabric is initially stretched or shrunk in a mold to give the desired shape. Then, the thermoplastic fibres inside the fabric are softened by applying heat. Finally, the temperature is lowered to a normal condition. This makes the fabric permanently shaped.

As a general guideline, the procedure is as follows:

Molding is the process of shaping fabric with heat and pressure. It is heated until the fabric becomes soft and pliable, and then it is pressed into a mold. As the fabric cools and hardens in the mold, it takes on the shape of the mold. In addition to creating complex shapes, molding is often used to join fabrics in ways that would be difficult or impossible to achieve by any other method.

Conclusion

Fabric joining can be done in a variety of ways, but each method has its own advantages and disadvantages. It depends on the specific application which method to use. For example, fusing is an excellent method for joining lightweight fabrics, while welding is an ideal method for joining heavy-duty fabrics. A variety of adhesives can be used to join fabric, and molding is a good method for creating complex shapes.

Fabric joining using alternative methods is becoming increasingly popular. These methods offer a number of advantages over sewing, and they are also becoming more affordable and accessible. As a result, more alternative fabric joining methods will be used in the future.

Aw, this was a very nice post. In thought I would like to put in writing like this additionally ? taking time and actual effort to make an excellent article? however what can I say? I procrastinate alot and by no means appear to get something done.

Stay with us