Name of the Experiment:

Study on anatomy of sewing machine needle used in garments manufacturing.

Introduction:

Considering that precision and efficiency are paramount in garment production, it becomes imperative to understand the intricate details of sewing needles. This report will explore the dynamic anatomy of these needles and the significant role they play in the manufacturing process, starting at their tip to their butt. With a keen focus on garment manufacturing, our goal is to discover the hidden secrets within the tip to butt of sewing machine needles. Our analysis will give us valuable insight into how the needles contribute to the durability and quality of stitched garments by dissecting each component and analyzing its functions. We will explore the anatomy of precision stitching from the needle’s tip, where fabric penetration begins, to its robust butt, where it connects to the sewing machine. Our study encompasses a variety of aspects, including needle materials, sizes, and designs, as well as their impact on the stitching process. In addition, we will analyze the connection between needle selection and fabric types, and how needle anatomy affects stitch formation, seam strength, and overall garment quality. By conducting experiments, collecting data, and analyzing results, we aim to provide a comprehensive understanding of the dynamic anatomy of sewing machine needles and their direct relevance to garment production. This study will provide professionals, researchers, and enthusiasts with insights into needle selection that will help them optimize the efficiency, durability, and aesthetic appeal of stitched garments. As we journey from the tip to the bottom of sewing machine needles, we will unravel their dynamic anatomy and uncover their crucial role in garment manufacturing. Take a look at sewing machine needles and discover how to enhance the garment industry’s productivity and quality.

Objectives:

- To learn the names of the different parts of a sewing needle.

- To learn more about the different functions of the various parts of the sewing needle.

- Investigate the influence of needle sizes and designs on stitch formation and garment quality.

Function of sewing needle:

- Accurately penetrates the layers of the fabric in a smooth and controlled manner.

- The needle forms stitches when it passes through fabric.

- Provides a path for thread to be guided from the spool to the needle’s eye.

- Keeps thread tension at the right level during stitching.

- Creates stitches by engaging the needle thread with the fabric.

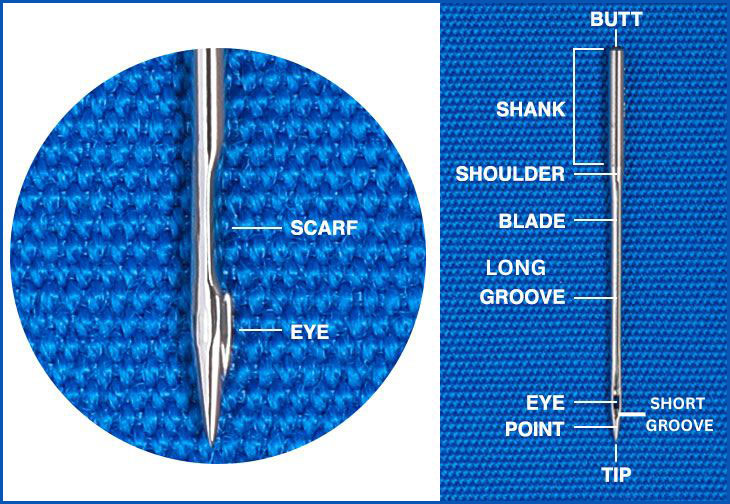

Anatomy of Sewing Needle:

Different parts name of sewing needle:

- Butt: The first portion or base of a needle is a section that is made in a particular shape, by which the needle can be attached to the needle bar easily and fairly by keeping the needle shape as defined as possible.

- Shank: In needles, this is the part of the needle that is attached to the needle bar. The shank may be cylindrical or there may be a flat end on one side. This part of the needle is thicker and stronger compared to the rest of the needle and it serves as a support for the needle as it works.

- Shoulder: A shoulder is a part of the shank that connects the blades to the shank. When a needle penetrates the fabric and reaches its lowest bottom destination, it also penetrates the fabric with the shoulder, so that the hole that is made by the needle head is increased, as a result of that shoulder. As the needle comes out of the fabric with needle thread, there will be less friction between the needle and the fabric because the hole will be larger, in addition, the shoulder will strengthen the needle blade.

- Blade: It is the blade that extends from the eye of the needle to its shoulder that is the longest portion of the needle, and this is the part of the needle that usually gets in contact with fabrics.

- Long groove: From the shoulder of the blade to the eye of the needle, there is a long and narrow slot, referred to as a long groove, in the blade. As the needle thread penetrates the fabric downward, it stays in the gap of the long groove so that there is comparatively less friction between thread and needle. As a result, the thread and needle penetrate the fabric with comparatively less friction. In addition, as a result of less friction, less heat is generated in the needle and the possibility of damaging the needle thread is reduced as a result of friction or temperature.

- Short groove: There is a short groove at the same point where the hook or looper is placed on the needle. The groove extends from just above the needle eye to the bottom of the needle and it is responsible for forming the needle thread loop.

- Needle eye: The needle has a hole at the tip that is called the eye. It extends from the long groove to the short groove. It is very important to know the inside shape of the needle, especially since it is related to the needle thread being damaged or not when the needle penetrates the fabric, and it is also related to the needle thread forming the right loop. Buldged eyes are needle eyes with a much wider opening than a blade. Buldged eyes act as shoulders, but fine fabrics may be damaged during sewing.

- Scarf: Almost above the needle eye, there is a small slot called the scarf. This scarf is used to set the hook or looper closer to the needle so that it can hold the needle thread loop easily.

- Point: There is a part of the needle that extends from the eye to the tip known as the point. The needle point is designed in such a way that no damage is caused to the farbic during its penetration. If the needle is not determined properly which needle will be used for which fabric, then it may damage the fabric while it is being sewed.

- Tip: An essential part of the needle point is the tip, which is the end below where the needle enters the fabric. It is the tip that determines how well the needle penetrates the fabric.

Conclusion:

In the study of the dynamic anatomy of sewing needles used in garment manufacturing, it became evident that this essential tool has an intricate design that provides valuable insights into its intricate details. In order to accomplish high-quality stitching, researchers have studied the complex interactions between sewing needles and fabrics in meticulous detail, revealing how needle design and performance play a major role in achieving high stitching quality. As a student of our teacher, I would like to thank her for her support.

Wow, great blog.Really thank you! Really Great.

thanks too.

Wow, great blog post.Thanks Again. Fantastic.

thanks…

I am so grateful for your article.Thanks Again.

keep visit our site…..thanks too….

Im grateful for the blog post.Thanks Again. Keep writing.

ok

Looking forward to reading more. Great blog article. Will read on…

please support us…

At this time it sounds like WordPress is the top blogging platform out there right now. (from what I’ve read) Is that what you are using on your blog?

It’s going to be finish of mine day, however before finish I am reading this fantastic paragraph to increase my experience.

Thank you dear. Stay with us. Happy reading.

Im thankful for the blog post.Really looking forward to read more. Fantastic.

please support us.

Dead composed subject material, Really enjoyed studying.

please support us.

Hey, thanks for the article post.Thanks Again. Awesome.

keep visit our site.

Wow that was unusual. I just wrote an really long comment but after I clicked submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyhow, just wanted to say excellent blog!

Im obliged for the article.Really looking forward to read more. Really Cool.

Thanks

Terrific posts. With thanks. how to get motivated to do homework tok essay help

Thanks

Great post. I’m going through some of these issues as well..

It’s actually a great and useful piece of info. I am satisfied that you just shared this helpful information with us. Please keep us informed like this. Thanks for sharing.

I loved your post.Really thank you!

Im obliged for the article post.Really looking forward to read more. Really Great.

I really like and appreciate your blog.Really thank you! Keep writing.

Major thanks for the blog.Really thank you! Awesome.

I think this is a real great article. Want more.

ok, I will try…

Enjoyed every bit of your blog.Thanks Again. Awesome.

Great, thanks for sharing this article. Really Great.

Awesome stuff! I’ll be back to see more of your stuff. Great job!

Your style is really unique compared to other people I have read stuff from. Thanks for posting when you have the opportunity, Guess I’ll just bookmark this blog.

I really like and appreciate your blog article.Much thanks again. Really Cool.

Wow, great blog article.Much thanks again. Fantastic.

This is one awesome blog article.Thanks Again.

Thanks too…

Major thanks for the blog post.Much thanks again.

Thanks too……

I appreciate you sharing this article post. Awesome.

I appreciate you sharing this article. Really Cool.

Really informative blog.Much thanks again. Really Great.

Appreciate you sharing, great article post.Much thanks again. Want more.

Thanks a lot for the blog post.Much thanks again. Keep writing.

Very good blog post.Thanks Again. Great.

I truly appreciate this blog.Really thank you!

Wow, great blog post.Really thank you! Keep writing.

Thanks again for the blog post.Much thanks again. Really Great.

Thank you for your article post. Awesome.

Great, thanks for sharing this blog post.Much thanks again. Much obliged.

I really enjoy the post.Thanks Again. Will read on…

I truly appreciate this post. Keep writing.

Thanks a lot for the article post. Awesome.

I really like and appreciate your blog article. Keep writing.

Wow, great blog post.Really looking forward to read more. Will read on…

Very neat blog. Awesome.

Awesome blog post.Much thanks again. Cool.

I appreciate you sharing this post.Much thanks again. Much obliged.

Thank you for your blog.Really thank you! Really Great.

Hey, thanks for the article post.Really looking forward to read more.

Wow, great blog post.Thanks Again. Great.

Thank you ever so for you article.Much thanks again. Fantastic.

Really enjoyed this blog.Really thank you! Fantastic.

I really like and appreciate your article post. Keep writing.

Im grateful for the post.Really thank you! Fantastic.

Wow, great blog article.Really thank you! Keep writing.

Im grateful for the blog article.Thanks Again. Great.

Very neat post.Really thank you! Awesome.Loading…

I really like and appreciate your post.Really looking forward to read more. Much obliged.

I truly appreciate this blog post.Much thanks again. Keep writing.

Major thanks for the blog article.Much thanks again. Cool.

Very informative blog.Thanks Again. Fantastic.

A big thank you for your article post.Really thank you! Keep writing.

A round of applause for your post.Really thank you! Much obliged.

I think this is a real great blog article.Thanks Again. Want more.

Thanks designed for sharing such a nice opinion, article is pleasant, thats why i have read it fully

Thanks so much for the blog post.Really looking forward to read more. Will read on…

This is one awesome article post. Really Great.

A big thank you for your blog.Thanks Again. Want more.

Awesome blog article.Really thank you! Will read on…

Say, you got a nice blog post.

Thanks for sharing, this is a fantastic blog.Really thank you! Cool.

Hey, thanks for the blog article.Really looking forward to read more. Keep writing.

I really liked your blog.Really looking forward to read more. Really Cool.

I read this post completely about the resemblance of newest and previous technologies, it’s remarkable article.

Im thankful for the article.Thanks Again. Fantastic.

Im thankful for the blog post.Thanks Again. Great.

Im obliged for the post.Much thanks again. Really Cool.

I really liked your article.Much thanks again. Keep writing.

Wow, great blog article.Much thanks again. Cool.

I think this is a real great blog post.Really thank you! Much obliged.

Major thanks for the blog post.Really looking forward to read more. Will read on…

I truly appreciate this article.Thanks Again. Will read on…

Wow, great blog.Really thank you! Much obliged.

Very informative blog article.Really looking forward to read more. Much obliged.

I value the article post.Thanks Again. Really Great.

Great article.Thanks Again. Will read on…

Very neat blog.Thanks Again. Cool.

Really appreciate you sharing this article. Much obliged.

I really enjoy the blog article. Awesome.

Wow, great article post.Much thanks again. Awesome.

I think this is a real great article.Really thank you! Fantastic.

I truly appreciate this blog post. Want more.

Say, you got a nice article.Thanks Again. Awesome.

Major thankies for the blog post.Much thanks again. Awesome.

Just Browsing While I was surfing yesterday I saw a excellent article about

Thanks

I think this is a real great blog.Really thank you! Great.

Enjoyed every bit of your blog.Really thank you!

Thanks a lot for the article.Thanks Again. Great.

Great post. Keep writing.

I value the blog post.Really thank you! Awesome.

Thank you for your blog article.

Hi! Would you mind if I share your blog with my facebook group?There’s a lot of folks that I think would really enjoy your content.Please let me know. Cheers

It is really a great and helpful piece ofinfo. I’m satisfied that you just shared this useful info with us.Please stay us informed like this. Thank you for sharing.

Thanks. Stay connected

I value the article.Really looking forward to read more. Fantastic.

Great, thanks for sharing this article post.Much thanks again. Want more.

Very good blog.Thanks Again. Great.

Thank you for your post.Much thanks again. Really Cool.

I really enjoy the blog article. Fantastic.

Great, thanks for sharing this blog post. Keep writing.

Thank you for your blog post.Much thanks again. Much obliged.

Thanks in support of sharing such a fastidious idea, post is nice, thats why i have read it completely

Im thankful for the blog.Really thank you! Keep writing.

Really appreciate you sharing this article post. Much obliged.

Say, you got a nice blog. Fantastic.

Really informative blog.Really thank you! Really Cool.

A big thank you for your blog article.Really thank you! Want more.

Very informative blog post.

I really like and appreciate your article.Really thank you! Much obliged.

I really enjoy the blog. Much obliged.

Thanks for the post. Cool.

A big thank you for your blog.Much thanks again. Fantastic.

Awesome blog post.Thanks Again. Really Cool.

I appreciate you sharing this post.Really looking forward to read more. Cool.

I loved your post.Thanks Again. Want more.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Really informative article post.Thanks Again. Really Cool.

Thanks so much for the blog post.Thanks Again. Great.

Say, you got a nice post. Cool.

Thanks a lot for the blog post. Really Great.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis. Kerassentials is a convenient, easy-to-use formula. https://kerassentialsbuynow.us/

Really appreciate you sharing this article post.Thanks Again. Really Cool.

A big thank you for your blog post.Thanks Again. Keep writing.

Very informative blog post.Really thank you! Awesome.

Hey, thanks for the article post.Thanks Again. Cool.

Really appreciate you sharing this post. Will read on…

Very informative blog.Thanks Again. Awesome.

I value the post.Really thank you! Great.

I really enjoy the article post.Much thanks again.

Major thanks for the post. Awesome.

Thank you ever so for you article post. Keep writing.

I think this is a real great blog article.Thanks Again. Really Cool.

I think this is a real great article. Keep writing.