Introduction:

Scouring softens cotton fibers by removing fatty and pectic substances, preparing them to absorb the subsequent treatments. The scouring process is typically carried out using soft water that is infused with textile auxiliaries such as absorbing agents, detergents, emulsifying agents, caustic soda, Solvay lye and sequestering agents. Alkhali makes fiber swell and enhances surfactant action. Fabrics, filaments, and yarns can all be treated with this method. To make cotton fibers more easily wettable and enhance the subsequent absorption of finishing liquors, it is also possible to perform an enzymatic scouring process rather than the traditional scouring process. It is usually carried out via continuous or discontinuous systems, with the same machines used for downstream treatments; temperature, processing time, PH, concentration of reagents, and the type of machine used, all depend on the fiber. Dyeing and printing defects are usually caused by incomplete scouring processes due to varying degrees of wettability and inconsistent dye affinity.

Objectives:

- To know about cotton scouring.

- Come learn scouring effect on cotton fabric.

- To know how to estimate scouring effect of cotton fabric.

Apparatus:

- Before scouring fabric.

- After scouring fabric.

- Scissor.

- Weight balance.

- Calculator.

- Distilled water

- Direct dye.

Test procedure:

In this experiment, we will estimate scouring effect in three methods. They are:

- By weight loss.

- By absorbency test.

- Wicking test.

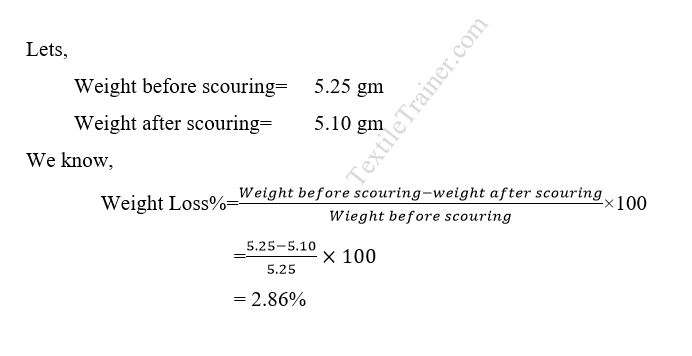

By Weight Loss:

Estimate scouring effect by weight loss is described below.

Here weight loss is 2.86% due to scouring. But standard range for weight loss due to scouring is 4-8%. Our sample can’t meet standard range. So we can say our sample is not enough scoured.

Absorbency Test:

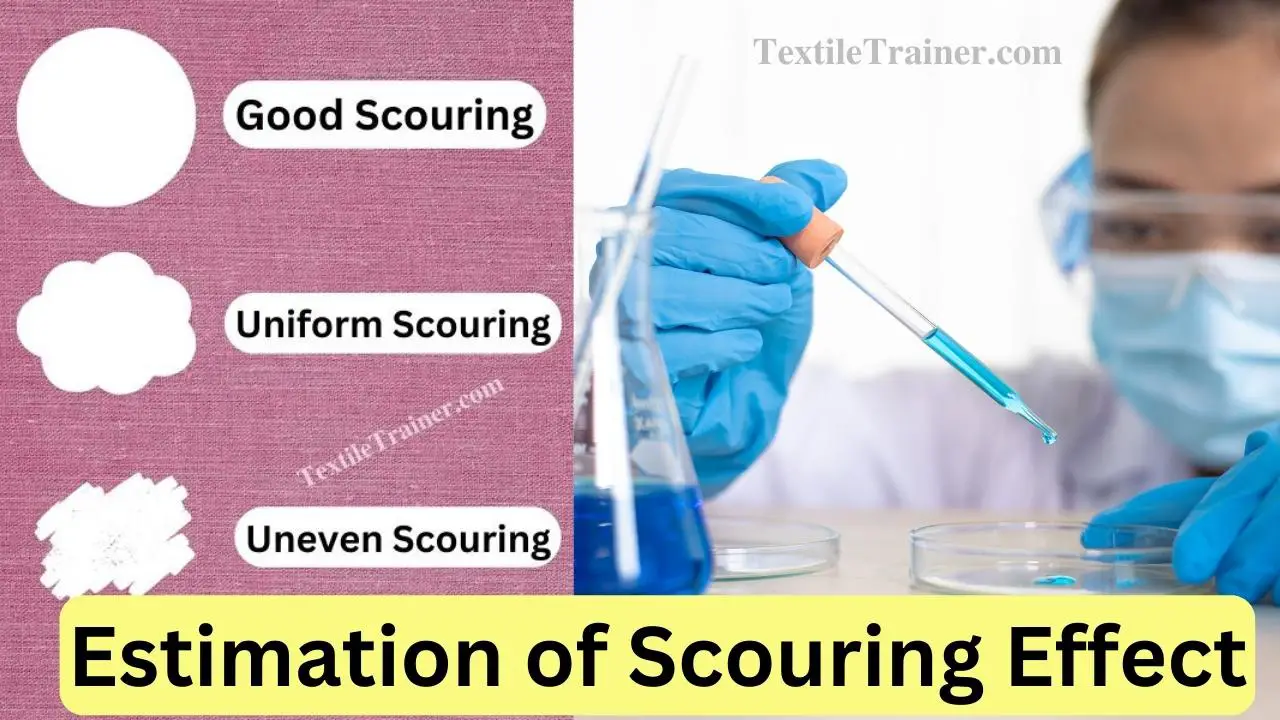

Estimation of scouring effect by absorbency may be done in three way. They are:

- Drop Test.

- Spot Test.

- Immersion Test.

1. Drop Test:

A pipet is used to take water, and water droplets are dropped on the scoured fabric, and their absorption is observed visually.

The standard absorbency time is between 0.5 and 0.8 seconds. It can take up to one second for one drop to absorb.

However, our sample took 5 seconds to absorb, so we can say that our sample was not well scoured.

2. Spot Test:

In a pipette, 1% direct red (Congo red) solution is taken and droplets are placed on the fabric at different locations. In the next step, the fabric absorption area is observed and compare with the below picture.

3. Immersion Test

- We will first cut 1×1 cm2 scoured fabric. After that, it remained on the surface of the water. A stop watch is used to record the time for immersing the fabric.

- Immersion takes 5 seconds as a standard

- Approximately 4.95 seconds are spent immersing our sample

- our sample is moderate scoured.

Wicking Test:

- A sample of 18cm x 5cm is cut from the scoured sample.

- Take 1% direct dye red color in a beaker.

- Then, 1 cm above the sample bottom, a marker is drawn.

- in the next step, the sample is hung from a wood stick while being immersed in dye liquor for 1 cm.

- After 5 minutes, we measured the point where the colored solution was absorbed straight above by the sample.

Standard range is 30-50 mm. Our sample average range is 35 mm. so our sample is moderate scoured.

Conclusion:

Well scouring of cotton fabric is an important factor in case of cotton fabric dyeing. so, it is most important to estimation of scouring effect. By this experiment, we know how to estimate scouring effect. From this experiment, we gain knowledge that is extremely useful in our everyday lives. We would like to thank our teacher for helping us complete this experiment.

Informative Article, Thanks for sharing.

Thank you too…..please stay with me. don’t forget to share my article with your friend and social media….

Loving the information on this site, you have done great job on the posts.

I really enjoy the blog post.Much thanks again. Fantastic.