How to Calculate Marker Efficiency in Garment Manufacturing

Name of the Experiment

Study on how to calculate marker efficiency in garment manufacturing department.

Introduction

A marker is a thin paper on which all components of a garment are drawn to reduce the fabric wastage in cutting section. In the garment industry, maker efficiency is an important factor. Because it directly influences fabric consumption. Besides, it also impacts on production cost of a garment. So, it is crucial to know how to calculate marker efficiency in the garment. Marker efficiency measures how effectively the fabric area is utilized in the marker paper. A higher marker efficiency means less fabric wastage. Let’s come the learn the definition of maker efficiency.

Marker efficiency refers to the percentage of the fabric area that is occupied by the actual area of garment pattern pieces in a given marker layout.

Marker efficiency formula is given below.

- Marker efficiency (%)= (Total area of garment pieces ÷ Total area of the marker)×100

Some factors influence the marker efficiency:

- Marker maker: Marker efficiency depends on the experience, skilled and technical knowledge of the marker maker. So, a marker maker should be a skilled person to make an efficient maker.

- Marker length: Longer markers often help arrange the pieces better.

- Fabric characteristics: Fabric characteristics is another factor. If the fabric with strips, or checks is difficult to arrange. It leads to more fabric wastage.

- Marker width: The marker width should be similar to the fabric width to minimize the wasted fabric on the edges.

- Garment size: garment size also impacts marker efficiency. Different sizes of garments can affect the efficiency of the marker.

- Marker length: Longer markers help arrange the pieces better.

- Marker making method: Computerized methods are usually faster than manual marker making process.

- Garment type: Simple garment styles are easier to arrange, but it is difficult to arrange complex styles. Complex styles may leave more gaps.

You may read: Marker Making Process in Garment Industry Step-by-Step

Objective

- To learn about marker making process.

- To understand how to calculate marker efficiency.

- To learn the factors that affect the efficiency of the marker.

Materials and Equipment

- Pattern paper

- Maker paper

- Pencil

- Eraser

- Measuring scale/tape

- Scissor

- Table for marker layout

- Calculator

Working Procedure

- Step-1: Calculate total area of garment pieces

- Initially, measure the area (length× width) of the pattern individually.

- Now, add up all the area to get the total area of garment components.

- Step-2: Calculate total area of the marker

- At first, measure the fabric width.Then, measure the marker length.

- Subsequently, multiply the fabric width and the marker length to get the total area of the marker.

- Step-3: Apply the marker efficiency formula

- In the previous steps (step-1 and step-2), we got the total area of garment pieces and the total area of the marker. Now, insert these two values into the marker efficiency formula to find the marker efficiency percentage.

Calculate Marker Efficiency

- Fabric width= 60 inches

- Maker length= 125 inches

- Total area of garment component= 6,000 square inches

- Total area of marker= ( fabric width × maker length)= (60×125)= 7,500 square inches

- Marker efficiency (%)= (Total area of garment pieces ÷ Total area of the marker)×100= (6000÷ 7500 )×100= 80%

- N.B.: A marker efficiency above 85% is considered good, 75% to 85% is acceptable. But if the efficiency is below 75% means need for improvement.

Conclusion

Calculating marker efficiency is an essential part of the cutting room in garment production. From this lab report, we come to learn how to calculate marker efficiency. This will help in future life.

More Lab Report

- Top 20 Tools for Garment Pattern Drafting in Fashion Design.

- Types of Industrial Sewing Machines with Simple Application.

- Sewing Needle Anatomy: Essential Parts and It’s Simple Function.

- Mechanism of Chain Stitch Formation with Dynamic Image.

- General Concepts of Different Fusing Technique to Ignite Your Skill.

- Mechanism of Lockstitch Formation with Dynamic Image.

- Types of Stitches Used in Garments with Proper Image.

- Different Types of Seam Used in Garments Industry with Proper Figure

- Study on Modern Flow Chart of Garments Manufacturing.

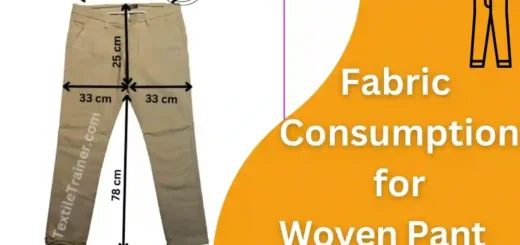

- Basic Pant Fabric Consumption Calculation : A Complete Easy Guide