Introduction:

There is no doubt that the draw frame is the quality filter of the spinning mill. When there is a mistake in the sliver of the draw frame, there will be defects in the yarn as a result. Thus, quality cannot be improved after the draw frame, meaning that sliver quality must be monitored carefully, metre by metre, at the last passage of the draw frame to ensure that the quality of the slivers meet the self-set quality standards at the drawing frame point.

Objectives:

- To know about draw frame.

- To learn important task of draw frame.

- To know passage diagram of draw frame.

- Come learn different parts name of draw frame.

Some important task of draw frame:

1. Equalizing:

The draw frame plays an important role in improving equal ness over short, medium, and long-term variations. Drawing is always equalized by doubling and can be equalized by auto-leveling an optional second process.

2. Parallelizing and straightening:

The fibers in the yarn must be arranged parallel to one another for the yarn to have optimum strength. To create this parallel arrangement the draw frame is responsible for creating it. As a result of every drafting step, it accomplishes this task by straightening the fabric’s fibers using the draft method.

3. Fiber orientation:

A sliver of fiber from a carding machine is oriented in all directions, contains a leading and trailing hook, and is crimped. During drawing, these un-oriented fibers become oriented towards the sliver’s axis. It is achieved by drafting in the draw frame method.

4. Blending:

Although modern blow room processes can achieve through blending, blending after carding improves the fiber composition of the sliver. When several slivers are fed through a draw frame and recombined at the front, the fibers in the individual slivers are blended well, resulting in a more uniform fiber composition across the length of the final sliver than a card sliver.

5. Dust removal:

During drawing, there is a high level of friction between fibers and fiber and metals during the drafting process, which makes the draw frame a good dust-removing machine. The dust from the incoming air is more than 80% on high-performance draw frames equipped with appropriate suction or removal systems.

Some important draw frame terms:

1. Drawing:

It is one of the processes used to manufacture yarn to draw the yarn after it has been carded. The share of drawing cost in yarn cost has minimal effect on the production cost of yarn, but the drawing process (draw frame) plays a significant role in enhancing the quality of yarn in many ways, such as evenness, strength, elongation at break, and degree of hairiness, which are all essential factors in making yarns suitable.

2. Doubling:

A doubling process involves feeding two or more carded slivers together. As a result of the drawing process, a combined sliver of the same linear density is obtained. In the doubling process, six or eight slivers are usually combined into a single sliver. As a result, the resulting sliver is more uniform, and linear density has been improved. During doubling, how can the evenness of the sliver be improved? By applying the law of doubling, we can understand this.

3. Drafting:

In the process of drafting, the input sliver is weighed less per unit length. In the sliver, hooked and curled fibers are straightened, and fiber arrangement is improved by making fibers parallel along their length. In the drafting process, fibers are blended. Sliver dust is also eliminated through the drafting process. A pair of drafting rollers are used to perform the drafting action. The rollers rotate higher during the drafting process.

4. Creeling and Doffing:

The process of replacing the cans of feed material at the back of the machine and joining the new can of sliver with the old can is referred to as creeling, and the process of removing the full delivery cans from the front of the machine is referred to as donning.

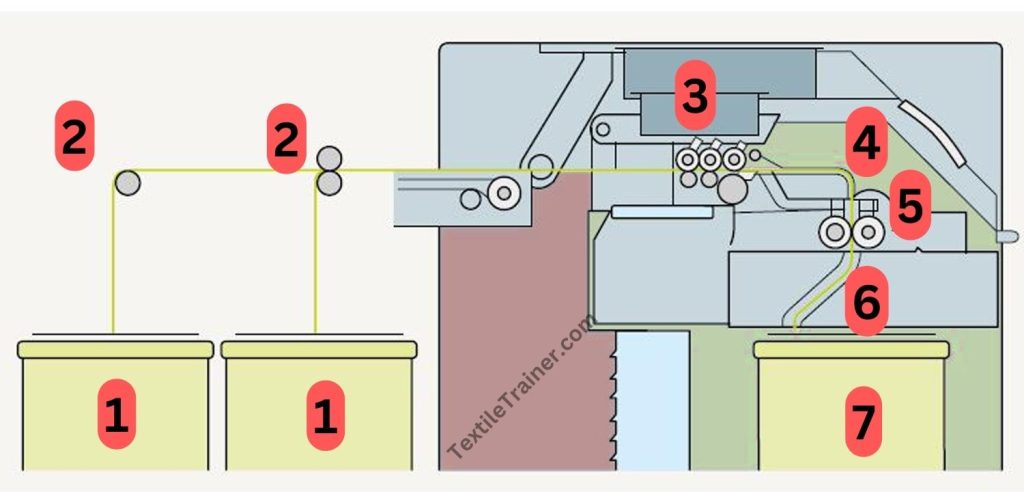

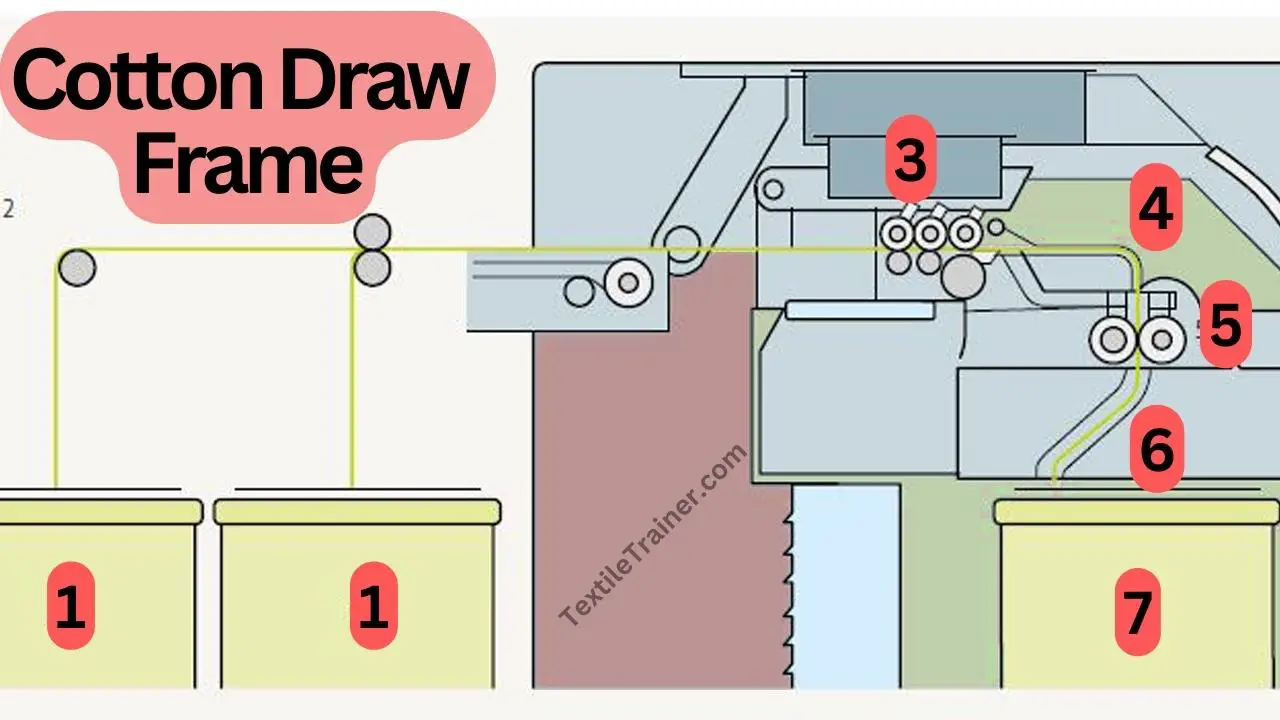

1= Card sliver can

2= Pair roller.

3= Drafting arrangement.

4=Tube

5= Calendaring roller

6= Sliver passage.

7= Draw sliver can

Working Principle of Draw Frame:

The drafting arrangement (3) receives four to eight card slivers. Each card sliver can(1) is topped with a pair of fed rollers (2). Positive drive is used to drive the fed rollers. The slivers running into the drafting arrangement(3) .The slivers runs into the drafting arrangement, are subjected to a draft of 4 to 8 and leave it as a web and condensed into a sliver immediately. It is then required that this sliver of metal is guided through a tube (4) via a passage (6) of the tube gear and into a can (7), in which it has to be laid in clean coils utilizing as much of the space as possible within the can by compressing the sliver and passing it through calendaring rollers (5).

Machine Specification:

| Raw materials | Cotton, man-made fibers, blends, fiber length up to 60 mm |

| Doubling [fold] | up to 8 |

| Feed [ktex] | 12 – 50 |

| Draft [fold] | 4.0 – 11.6 |

| Delivered sliver weight [ktex] | 1.25 – 7.00 |

| Delivery | 1 |

| Delivery speed [m/min] | up to 1 200 |

Conclusion:

Draw Frames are machines that double or combine slivers, blend and mix them, and level and attenuate them transiently, through a series of pairs of rollers, all at once. It is important to note that each pair of rollers in the drafting arrangement moves faster than the previous pair. During this experiment, we learned how the drawing machine worked, what the parts were called, and how it worked. In the future, this will be helpful to us in our job field.

Great article! The study on cotton draw frame on Textile Trainer provides valuable insights into optimizing cotton processing. The detailed analysis and findings are commendable. This resource is a must-read for textile professionals seeking to enhance productivity and quality. Kudos to the authors for sharing such informative content!

thank you for your comment…,please share my article….

Awesome article.Thanks Again. Much obliged.

thanks for stay with us.

Thanks a lot for the article. Awesome.

thanks too.

Thank you for your post. Keep writing.

keep visit our site….

Great, thanks for sharing this article.Thanks Again. Much obliged.

thanks too.

Wow, great article post. Want more.

keep visit our site..

I think this is a real great article.Much thanks again. Keep writing.

thanks too. please support us.

Major thanks for the blog article.Thanks Again. Really Great.

thank too…..please support us…

I value the blog post.Really looking forward to read more. Really Great.

keep visit our site…

Thanks so much for the post.Thanks Again. Much obliged.

thanks too.

Appreciate you sharing, great blog post.Really looking forward to read more. Much obliged.

I’d have to test with you here. Which is not one thing I usually do! I take pleasure in studying a post that will make folks think. Additionally, thanks for permitting me to remark!

imagine apartments appleton apartments for rent

I value the blog.Really looking forward to read more.

keep visiting our site…

Enjoyed every bit of your blog.Much thanks again. Awesome.

Great article post. Keep writing.

keep visit our site…

I truly appreciate this blog article.Really thank you! Awesome.

thanks too….

Muchos Gracias for your article post.Really looking forward to read more.

Im obliged for the article.Much thanks again. Much obliged.

Thanks for sharing, this is a fantastic blog.

Awesome blog.Much thanks again. Will read on…

keep visit our site.

I think this is a real great article.Thanks Again. Will read on…

Thanks too……

Really appreciate you sharing this post.Really looking forward to read more. Will read on…

thanks too…..

Awesome post.Thanks Again. Much obliged.

I really like and appreciate your article post.Thanks Again. Awesome.

A round of applause for your blog article.Thanks Again. Cool.

Thank you ever so for you blog article. Much obliged.

Thanks for the blog article.Really thank you! Much obliged.

Thanks for the blog article.Thanks Again. Awesome.

I think this is a real great article. Awesome.

Major thankies for the article post. Cool.

I really enjoy the blog article.Really thank you! Really Cool.

I truly appreciate this blog. Will read on…

Hey, thanks for the blog article. Cool.

I really liked your blog. Fantastic.

A round of applause for your blog article.Thanks Again. Much obliged.

Im grateful for the blog article.Thanks Again. Really Great.

I really enjoy the post.Really looking forward to read more.

Major thanks for the blog post.Thanks Again. Really Cool.

I truly appreciate this blog.Thanks Again. Fantastic.

Very neat blog post.Really thank you! Keep writing.

A big thank you for your article post.Really looking forward to read more. Great.

A big thank you for your post.Thanks Again. Awesome.

Welcome

Thanks for sharing, this is a fantastic blog article.Really thank you! Will read on…

Enjoyed every bit of your blog article.Much thanks again. Fantastic.

I really liked your article.Really looking forward to read more. Really Great.

Great post.Thanks Again. Great.

I value the article post.Much thanks again. Great.

Im grateful for the post.Thanks Again. Fantastic.

I appreciate you sharing this post.Really looking forward to read more. Want more.

Thanks for sharing, this is a fantastic blog article.Much thanks again. Really Great.

Very good article post. Keep writing.

Thanks for the blog post. Great.

I really enjoy the post.Much thanks again. Really Cool.

Very neat blog article. Awesome.

Great blog post.Really thank you! Want more.

I truly appreciate this article post.Much thanks again. Really Cool.

I appreciate you sharing this blog.Really looking forward to read more. Great.

Im grateful for the post.

Really informative blog post.Really thank you! Will read on…

Very neat article.Really thank you! Really Cool.

Hey, thanks for the blog article.Really thank you! Really Great.

I truly appreciate this blog article. Fantastic.

wow, awesome article.Much thanks again.

Awesome article.Really looking forward to read more. Really Great.

Looking forward to reading more. Great blog article. Fantastic.

wow, awesome article. Will read on…

I am so grateful for your article.Thanks Again. Will read on…

Great article post.Much thanks again. Awesome.

Very good blog article.Thanks Again. Great.

Awesome post.Really thank you! Great.

Appreciate you sharing, great blog. Fantastic.

This is one awesome article post.Thanks Again. Want more.

Im grateful for the article post.Thanks Again. Great.

I truly appreciate this blog article.Thanks Again. Keep writing.

Really enjoyed this post. Will read on…

Thanks a lot for the article.Thanks Again. Want more.

Very neat article.Really thank you! Great.

I am so grateful for your blog. Much obliged.

Appreciate you sharing, great article. Fantastic.

I really enjoy the blog article. Much obliged.

Wow, great post.Thanks Again. Great.

Thanks for sharing, this is a fantastic article post.Really thank you!

Really enjoyed this blog. Keep writing.

I loved your article.Thanks Again. Really Cool.

There’s certainly a lot to know about this issue. I love all of the points you have made.

I truly appreciate this blog article.Really thank you! Much obliged.

Hey, thanks for the post. Fantastic.

I loved your blog article.Much thanks again. Want more.

Thanks so much for the post. Will read on…

I really enjoy the blog post.Thanks Again. Want more.

wow, awesome article. Really Cool.

Thanks for sharing, this is a fantastic post. Want more.

Fantastic post.

I loved your blog article.Really thank you! Really Cool.

I loved your article post.Much thanks again. Keep writing.

I really enjoy the post.Really looking forward to read more. Great.

Wow, great blog post.Really looking forward to read more. Really Cool.

Very informative article.Much thanks again.

Very informative article post.Really thank you! Great.

Really enjoyed this post. Cool.

Enjoyed every bit of your blog article.Much thanks again. Great.

I think this is a real great article post. Much obliged.

Hey, thanks for the blog post.Much thanks again. Really Cool.

Very good article post. Awesome.