1. What is Weaving?

Weaving: The action of producing fabric by the interlacing of warp and weft threads is called weaving.

In other words, weaving is the process of interlacing two sets of yarns at right angles. The threads that lie along the fabric’s length are termed warp threads, and the threads that lie across the width are termed weft threads at right angles of warp threads and are interlaced with each other to form a fabric. In a nutshell, we can say warp threads run parallel to the weaving machine, and weft threads run perpendicular to the loom. Warp threads are called ends, and weft threads are called picks or filling threads. I will present a flowchart of weaving or woven fabric in this article. 2.

2. Flow-Chart

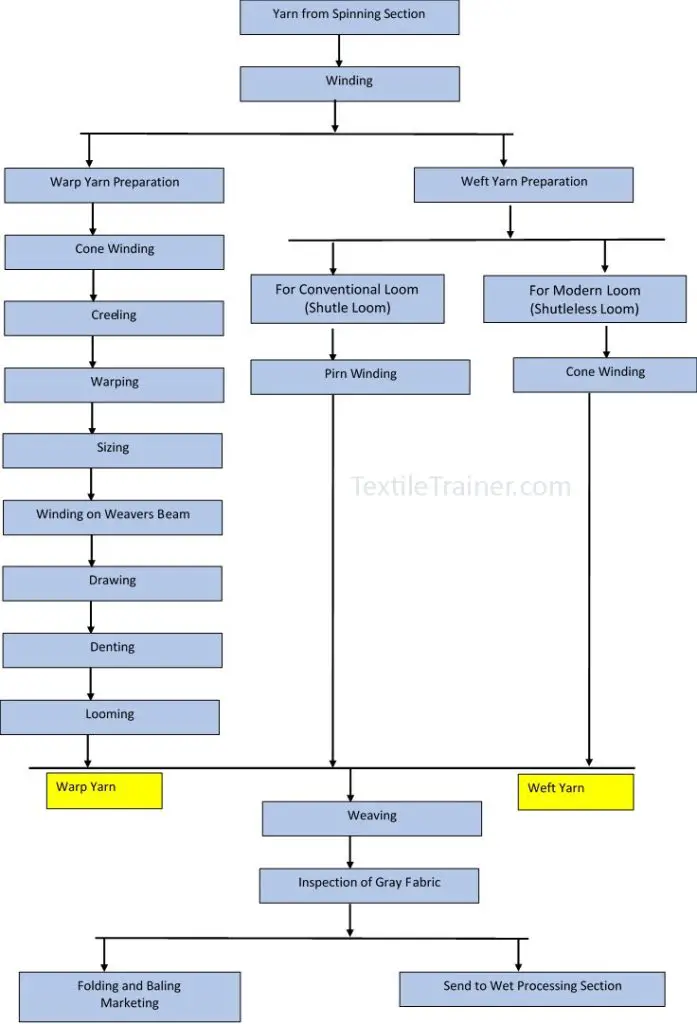

Flow-chart of weaving or woven fabric:

Now I will briefly discuss different terms used in the flow chart. So that, It will be easy for you to understand the whole process of weaving or woven fabric manufacturing.

2.1 Yarn from Spinning Section

Yarn From Spinning Section: Yarn is the raw materials of weaving. Yarn comes from spinning section to weaving section. Spinning section send different types of yarn according requirement of weaving section.

2.2 Winding

Winding: The process of transferring yarns from ring bobbins or hank into a suitable package for weaving is called winding.

2.3 Creeling

Creeling: The process for holding supplied packages on creel is called creeling. In another word, Creeling is the process of placing complete packages in a place that is ready to be unwound as a section of transfer operations.

2.4 Warping

Warping: the parallel winding of warp yarn in sheet forms from many small winging packages on to a warp beam is called warping.

2.5 Sizing

Sizing: The process of applying a protective adhesive coating materials on the yarns surface is called sizing. Sizing is applied only warp thread. It is the important operation in weaving section. Weaving efficiency depend on sizing. Because due to sizing applied on warp yarn, increase elasticity, strength, frictional resistance and smoothness of warp yarn.

2.6 Drafting

Drawing or Drafting: warp yarns are drawn through the heald eye by the drawing hook according to the design or pattern of the fabric is called draw-in or drafting.

2.7 Denting

Denting: the warp yarns are drawn through the dent of the reed by the drawing hook according to the design or pattern of fabrics is called denting.

2.8 Looming

Looming: the process involved in preparing a weaver’s beam is set on the loom bracket at the back side of the loom is called looming.

2.9 Pirn Winding

Pirn winding: pirn is used in shuttle for weft yarn through the shed.

2.10 Weaving

Weaving: the process of producing fabric by the interlacing of warp yarn and weft yarn is called weaving.

2.11 Inspection of Grey Fabric

Inspection of Grey Fabric: after weaving, fabric is inspection to determine different fault of fabric and solve the fabric fault. So we can say, the activity such as testing, gauging, measuring and other characteristics of grey fabric that comparing with specified requirements of buyer is called inspection.

2.12 Send to Wet Processing Section

Send to wet processing section: after inspection, grey fabric is send to the wet processing section. Here different wet process such as sourcing, bleaching, dyeing etc. are done on fabric according to requirements of buyer.

2.13 Folding, Bailing and Marketing

Folding, bailing and marketing: Mainly folding and bailing action are done for grey fabric marketing. If everything is okay, then grey fabric sent to the market.

2.14 Conclusion

Conclusion: Woven fabrics are composed of longitudinal or warp threads and transverse or weft threads, interlaced with one another according to the class of structure and form of design that are desired. However in this article I tried best to present universal flow chart of weaving or woven fabric. If you have confusion about the flow chart, please comment here. Don’t forget to share the post with our friend and different textile page or textile related group.

2.15 Reference

- Introduction of Textile Engineering by MD. SAJJAK HOSSAIN

- Understanding of Textiles for a Merchandiser by DR. BELAL

Informative Post. Keep Updating.

thank you for support and stay with us.