Jeans Tie Wash Recipe: Easy 6 Steps & Industrial Method

Introduction

The jeans tie wash process involves tying the garments before washing. As a result, uneven crease marks appear on the garments. These crease marks create a vintage-looking look. Initially, the garments are tied according to the standard sample. Then, they are washed in a washing machine. Basically, for tie wash, only enzyme or bleach wash is carried out on the sample. After washing, cut the tie and match it with the standard sample.

Objectives of Tie Wash

- Tie wash gives the vintage or street-style of the garments.

- Create high-contrast on the garments

- Tie wash helps to achieve different patterns like swirls, streaks, or marbling on denim.

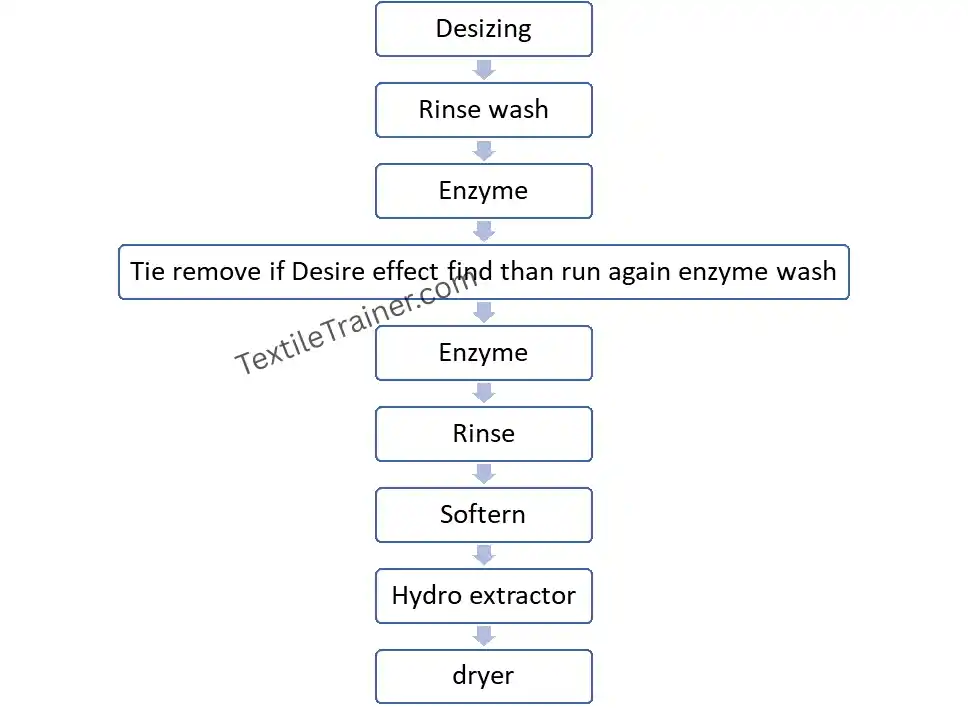

Flow Chart of Jeans Tie Wash

Typical Recipe for Jeans Tie Wash

Following the jeans tie wash recipe for 50 pcs jeans. Recipe has been collected from washing industry of the Bangladesh.

| Process | Water(L) | Time(min) | Temperature(0C) | pH | Chemical | Chemical Qty(gm) |

| Desizing | 200 | 15 | 60 | Desizing agent | 70 | |

| L.P-30 | 70 | |||||

| Rinse(2times) | 300 | 3×2 | cold | |||

| Enzyme | 200 | 5-10 (check) | 45 | Neutral Enzyme | 600 | |

| Anti back staining | 150 | |||||

| Tie remove | ||||||

| Rinse(2times) | 300 | 3×2 | cold | |||

| Softener | 150 | 5 | Cold | Mesoft-ccs Flakes ( cataionic) | 250 | |

Working Procedure

Step-1: Desizing

- Load the machine of 200 L of water.

- Now, load the garment in the machine.

- Add desizing agent and L.P-30 according to the mentioned recipe.

- Now, set the temperature 600 C and run the machine for 15 min.

- After 15 min, drain out the water.

- Purpose: Desizing process remove the size materials from the denim pants.

Step-2: Rinse

- Add 300 L of water in the machine.

- Run the machine for 3 min.

- Do it 2 times

- Purpose: Rinsing process remove residual chemicals and loose impurities of the garments.

Step-3: Enzyme wash

- Add the 200 L of water.

- Then, add neutral enzyme (powder) and anti-back staining agent.

- Set the machine temperature 450 C and run the machine for 10-15 minutes.

- After 10-15 minutes, check the tie effect. If desire tie effect find, then cut the tie.

- After cutting tie, run enzyme wash process again for 10-15 minutes agains.

Step-4: Rinse

- Add 300 L of water in the machine.

- Run the machine for 3 min.

- Do it 2 times

- Purpose: Rinsing process remove residual chemicals and loose impurities of the garments.

Step-5: softener

- Add 150 L of cold water and cationic softener

- Run the machine for 5 minutes

- Purpose: Increase the softness and hand feel of the garments.

Step-6: Hydro-extractor and drying

- Now, garments send to the hydro-extractor section. In hydro-extractor section, extra water removes from the garments

- Finally, dryer the garments to dry.

Advantage of Jeans Tie Wash

- Tie wash helps to create different looks and offering a artistic style.

- This wash allows the jeans to be sold at a higher price.

- It creates vintage looks.

Disadvantage of Tie Wash

- It is hard to control tie pattern.

- It is not ideal for mass uniformity. Because, it is difficult to replicate the exact same effect on a large batch.

- It is more labor intensive as well as time consuming.

Conclusion

The jeans tie wash process is a creative and fashionable process. It enhances the appearance of the denim garments. Though the jeans tie wash process has some demerits, it creates extra market value for the garments.

References

- Hossain, M. F. (2015). Practice of Textile Coloration, Volume-I. Dhaka: Books Fair Publications.

- Jalil, P. D. (2018). Denim and Washing Technology. Dhaka: Granthanir Prokashoni.

- Rahman, E. M. (n.d.). Practical Hand Book of Washing and Dyeing. University campus.

You May Read:

- How to Acid Wash Jeans Pant

- Top 15 Best Jeans Brands for Women in the World

- Most Common 10 Dry Process in Garments Washing

- Flow Chart of Garments Washing Plant with Easy Description

- Dry & Wet Process Machines in Garments Washing Plan

- All Types of Wet Process in Garments Washing Easy Explanation

- Top 25 Chemicals Used in Washing Plant & Chemical Function