All Types of Wet Process in Garments Washing Easy Explanation

1. What is the Wet Process??

The process that is done in wet conditions is called wet process. In garments washing industry, there are two types of processes. One is wet process and another is dry process. There are so many wet processes in the garments washing industry. In this article, I will present different types of wet process in garments washing and described all types of wet process step by step.

2. Types of Wet Process in Garments Washing

There are 2 types of wet process used in garment washing plant. They are:

- Pre-treatment process

- Washing process

- Chemical washing process

- Enzyme washing process

- Bleaching process

- Acid wash

- Towel wash

- Tie wash

- Resin wash

- Over dyeing

- Mechanical washing process

- Stone wash

- Bio-stone wash

- Chemical washing process

Now, I will brief all the types of wet process used in denim washing one by one.

2.1. Pre-treatment Process

In denim washing plant, pre-treatment process is the first and most important step. It determines whether a denim garment will look good or bad depending on this process. This process removes impurities, starch, and stains, preventing streaking and stiffness. It is also called de-sizing process. The woven fabric contains sizing materials to strengthen the warp yarn during weaving. This process removes the sizing materials.

Methods used for De-sizing in denim washing:

Below methods are used for de-sizing process in denim washing plant.

- Washing with high acidic agents. (acetic acid)

- Washing with high alkaline agents. (soda ash)

- Washing with oxidative chemicals. (hydrogen peroxide)

- Enzymatic de-sizing with alfa amylase. This is eco-friendly and convenient.

2.2 Washing Process

There are two types of washing process is used in denim washing plant.

- 2.2.1 Chemical washing

- 2.2.2 Mechanical washing

2.2.1 Chemical washing

Chemical washing process of denim garments is described below.

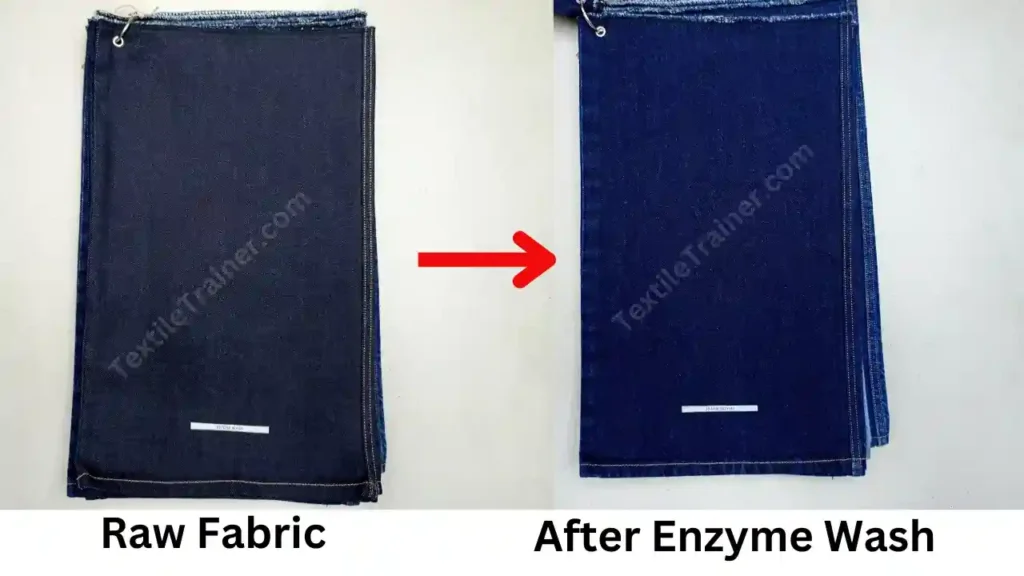

Enzyme washing process

It is an environmentally friendly wash. It involves applying organic enzymes to the fabric that consume the cellulose. Once the desired color is achieved, the enzymes can be stopped by altering the bath’s alkalinity or temperature. The post treatment includes rinsing and softening. There are four kinds of enzymes are used in denim washing process.

- Amylase: it is used for de-sizing process.

- Cellulase: it is used for salt and proper effect and contrast.

- Laccase: It is used for bio-bleaching process.

- Catalase: it is used for per-oxide killer

There three categories’ enzymes are used in denim washing plant.

- Neutral enzyme: Neutral enzyme gives better salt and pepper effect with very less back staining.

- Acid enzyme: Acid enzyme gives faster result but with too heavy back staining.

- Hybrid enzyme: It is the combination of neutral enzyme and acid enzyme. It gives better result and also cost effective.

Bleaching Process

This process is an important step in denim washing process. Bleaching agent break the indigo color structure and create fading effect and old looking. This process is difficult to control. Bleaching process should be handle carefully. Otherwise, strength of denim garments will be decreased. Basically, there are four types of bleaching agent is used in garments washing plant. They are:

- Calcium hypo chlorite: This bleaching agent is commonly used in garments washing plant. It is used to get medium to vintage shade.

- Sodium hypo chlorite: This is also commonly used in denim washing process and used for medium to vintage shade.

- Hydrogen peroxide: When low color loss is desired or if the fabric is sulphur-top, hydrogen peroxide is used. However, it takes more time to provide desired results.

- Potassium permanganate: The potassium permanganate is also being used to bleach or reduce 100% sulfur black denim fabrics to create unique effects. It is not production friendly until the garments washing industry has an exceptionally skilled team to handle it. Otherwise, the bleaching process will result in many shades and casts. In order to eliminate fabric strength, bad smell, yellowing, skin irritation, etc., it is essential to proper neutralize after the bleaching process.

Acid wash

This is the oldest of fashion washes in denim after stone wash. In old recipes, this wash was carried out using acid. It is now carried out using oxidation agent. It is safer and more economical to use bleach or oxidative than acid. Various chemicals are used, but sodium hypochlorite and potassium permanganate (KMnO4) are commonly used. Acid washing is done by soaking pumice stone in hypochlorite, and occasionally KMnO4 is substituted for bleach.

Towel wash

This wash is one kind of uneven wash, similar to acid. In this wash, the towel is cut into small pieces and then dipped in bleaching solution or KMnO4 solution. The towel is then squeezed slightly, then tumbled together in the washing machine for a specified amount of time. Sometimes, garments have to check for desired shade. Finally, the denim garments are neutralized with neutralized agent to get a towel wash effect.

Tie wash

This wash is another wet process in garments washing. The tie wash is done by tying the garments and washing them, resulting in a look of uneven creases. In tie wash, at first, tie the garments according to standard, then we wash them. The wash is basically an enzyme or bleach wash. However, we cut the tie after the wash and then get the tie effect on denim pant.

Resin wash

As, we used resin directly in the wash, so that it is called resin wash. Resin was used in a specific percentage here. In order to get the shine look and when we wanted a lighter hand feel, we used resin wash. This wash fixes the color with fabric. The percentage of resin used depends on the standard requirements.

Overdyeing

An over dye is applied to the fabric or jeans to give them another tone of color. The most commonly used over dye is yellow for a dirty look. It can also be applied with a spray gun or paintbrush for local coloring. Blue and black can be over dyed with bright contrasting colors for special effects. Currently, over dyeing is most successful with washed out indigo jeans dyed in luminous colors.

2.2.2 Mechanical Washing Process

Mechanical washing process used in denim washing plant is given below.

Stone Wash

Typically, stone washing is used by the denim washing industry in order to impart worn out appearances to newly assembled cloth garments. As well as increasing the softness and flexibility of denim garments, stone washing also contributes to their longevity. To achieve a soft hand and desirable look, freshly dyed jeans are loaded into washing machines and tumbled with pumice stones.

Bio-stone washing

Traditionally, blue denim faded as pumice stones act abrasively on its surface during stone washing. Today, denim finishers use a special enzyme known as cellulase. This enzyme loosens indigo dye from denim in a process known as “Bio-stone Washing”. The enzyme can replace a large number of pumice stones with a small dose.

Please watch the video to clean your concept

You may read:

- Latest Flow chart of Garments Washing Plant with Easy Short Description

- Most Common 10 Dry Process of Garments Washing with Easy working procedure and Proper Figure

- Easy 10 Differences Between Hand Sanding and Sand Blasting in Garments washing

- Machines Used in Garments Washing Plant with Easy Description/ Dry Process & Wet Process Machine List

- Top 15 Best Jeans Brands for Women in the World

- 20 Most Important Machine Used in Denim Washing Plant is Describe Easy way

- Best 10 Jeans Brands for Men in the world

- What is Garments Dyeing? Types of Garments Dyeing Machine Used in Garments Washing Plant

- 10 Most Important Difference between Denim and Jeans

- What is Denim? A Brief History of Denim is Described in Easy way-2023

- What is denim? 20 Different types of denim Fabrics are Described in Easy way