Knit Fabric Pilling Resistance Test using ICI Pilling Box Tester

Introduction:

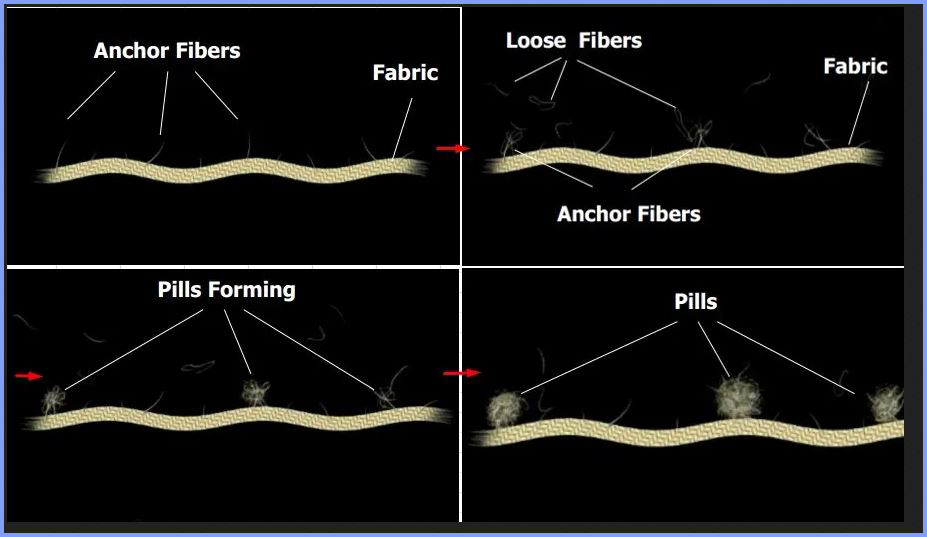

This experiment is about the knit fabric pilling resistance test using ICI Pilling Box Tester. Pilling is a fabric-surface fault characterized by little “pills” of entangled fiber clinging to the cloth surface and giving the garment an unsightly appearance. The pills are formed during wear and washing by the entanglement of loose fibers that protrude from the fabric’s surface. Under the rubbing action, these loss fibers develop into small spherical bundles anchored to the fabric by a few unbroken fibers. Should stray foreign fibers become part of the pills, then the color of the pills may differ from the body of the garment, and the fault is emphasized.

Pilling has long been recognized as a fault, especially in fabrics such as woolen knitted goods made from softly twisted yarns, but the introduction of newer man-made fibers appears to have aggravated its seriousness. An explanation is that with wool, the fibers which anchor the pills to the fabric are relatively weak, and the pills break away fairly easily, whereas fibers like Terylene, Orlon, Nylon, etc., are strong, and the pills remain key to the garment, accumulate, and become more and more unsightly.

Objectives:

- To know about pilling.

- To understand how to prepare the specimen for the pilling test.

- Come to learn the working procedure of ICI pilling box tester.

Apparatus:

- ICI pilling box tester

- Scissor

- Scale

- Sewing thread

- Sewing needle

Standard testing temperature:

An atmosphere at the prevailing barometric pressure with a relative humidity of 65% and temperature of 200 C is called standard testing temperature.

Specimen preparation Pilling Resistance Test:

Four specimens each (5×5) inch are cut from the fabric for this experiment. A seam allowance of 12 mm is marked on the reverse of each square. In two of the specimen, the seam is pronounced parallel to the warp direction. Other two parallel to the weft direction. The samples are also folded face to face, and a seam is sewn on the pronounced line.

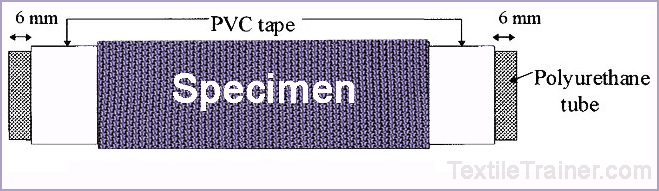

The gives two specimens with the seam parallel to the warp and two with the seam parallel to the weft. Each specimen is turned inside out, and 6 mm is cut off each and of it, removing any sewing distortion. The fabric tubes made are also mounted on rubber tubes so that the length of the tube showing at each end is the same. Each of the loose ends is taped with PVC tape so that 6 mm of the rubber tube is left exposed, as shown in the figure:

Working procedure Pilling Resistance Test:

- First, we have to clean the pilling box.

- Now, put the 4 sets of the specimen into the box.

- After putting the specimen into the box, firmly close the lid.

- Then, turn the counter to the required number of rotations.

- The number of rotations depends on the buyer agreements. But in the absence of agreement, the coarse fabric was turned over 7200 rpm, and the fine imitation fabric was turned around 14400 rpm.

- After complete pre-set rotation, the machine will be off automatically.

Assessment:

The specimens are removed from the tubes, and a visual assessment is done. The specimens are given a rating of between 1 to 5 with the help of the descriptions in the table:

| Grade | Description |

| 1 | Dense surface fuzzing and/or severe pilling. Pills of varying size and density covering the whole specimen surface. |

| 2 | Distinct surface fuzzing and/or distinct pilling. Pills of varying size and density covering a large proportion of the specimen surface. |

| 3 | Moderate surface fuzzing and/or moderate pilling. Pills of varying size and density partially covering the specimen surface. |

| 4 | Slightly surface fuzzing and/or partially formed pills. |

| 5 | No change. |

Conclusion:

From this experiment we came to learn about pilling. we also learn about ICI pilling box tester. This experiment will help in our future life. Thanks to our teacher to helping us.

References:

- Booth, J. (2008). Principles of Textile Testing. New Delhi: CBS Publishers & Distributors.

- Hamby, E. B. (1993). Handbook of Textile Test and Quality Control. New York: Wiley Eastern Limited.

- HU, J. (2008). Fabric Testing. New York: Woodhead Publicatioing Limited.