Modern Yarn Manufacturing Flow Chart: Carded & Combed Yarn

This article is about the latest yarn manufacturing flow chart. Basically, there are two types of yarn mainly. One is carded yarn and the other is combed yarn. There are marginal differences in the process of carded yarn and combed yarn. This article is about the modern flow chart of yarn manufacturing including carded yarn and combed yarn manufacturing process. Before going to the modern flow chart, let’s come to learn what is carded yarn and combed yarn?

What is Carded Yarn?

Yarn is produced from fibers that have only been carded but not combed. In the spinning factory, fiber materials are first opened and cleaned. If necessary, blend two or more fibers together in the first stage. Then fiber converts into individual fibers on a card and produces a sliver called a card sliver. Card slivers are fed on a draw frame to give drafting. Drafting leads to a reduction of the fiber mass per sliver and produces a draw frame sliver.

Compared to the carded sliver, the drawn sliver better show a better fiber alignment towards the longitudinal axis of the sliver. Drawn slivers also show a higher degree of parallelization between the fiber. Finally, a yarn spun out of this sliver is called a carded yarn.

What is Combed Yarn?

In yarn production, both carded and combed fibers are used. In combed yarn, the combing process is used as an additional process besides carding. During this process, fibers are arranged in a highly parallel pattern, and different short fibers, neps, and trash are removed. As a result, the quality of the combed yarn is high, with excellent strength and evenness. On the other hand, combing leads to a higher degree of cleanliness in fiber materials. Compared to carded yarns, the combed yarn has a softer handle.

Yarn Manufacturing Flow chart with a modern Blow room line

Now, let’s come to learn details of flow chart of yarn manufacturing

1. Automatic Bale Opener:

this is first machine of blow room line. Cotton fibers comes in spinning in bale form. Bale is a standard sized and weighted pack of compressed cotton lint after ginning. Compressed cotton fiber need to open. Automatic bale opener, open the compressed cotton. The first generation automatic bale opener machines were mostly stationary. Only the bales were moved, either forward and backward or in a circle. But now automatic bale opener machines are traveling type. They move past the stationary bales of the layout. The main task of automatic bale opener is open the compressed cotton evenly from bales, mixing and blending, form tufts of equal size.

Metal detector:

Magnets are used in blow room lines to remove metal such as iron from the cotton. We know cotton fiber is processed and made bale in ginning factory. From the factory, metal substances may be mixed with cotton fiber. Metal detectors remove this metal from the fiber.

3. Uniclean:

One of the most essential and primary tasks in the blow room is removing dust, trash, leaf, and other waste from natural fibers, especially cotton. Uniclean is used in blow room lines to remove dust, trash, and other impurities from the fiber.

4. Unimix:

Another function of the blow room is to blend the raw material of different qualities to equalize and even the mean quality of delivered materials. Because natural fiber remains variable in quality. Unimix help mix various quality fiber into each other. The latest version Unimix machine has three chambers: a storage section, an intermediate chamber, and a delivery section. 8 chutes are feed behind the machine in a storage section.

5. Uniflex:

A uniflex machine is used for cleaning purposes. A fan draws the tufts by suction from the previous machine, and a distribution element ejects them into a filling chute. The rear wall of the chute consists of individual aluminum lamellae with slot openings through which the air can escape. This is the first de-dusting step.

6. Vision Shield:

An essential quality objective is to produce contamination-free yarn. Vision shield is used to produce contamination-free yarn. Today’s textile markets are highly competitive. Every buyer wants unique products of the right quality and free from contamination. A vision shield is used in the blow room line to fulfill the buyer’s requirement. Here advanced technology is used for clean cotton with minimum loss of valuable fiber.

7. Condenser:

Condenser used in blow room line as a storage device. This is a very important part of the blow room. The main task of the condenser is to take fibers from the previous machine and supply them to the next machine. Condenser ensures regular feeding of the machine. It consists of a fan, a perforated roller, and a stripping roller.

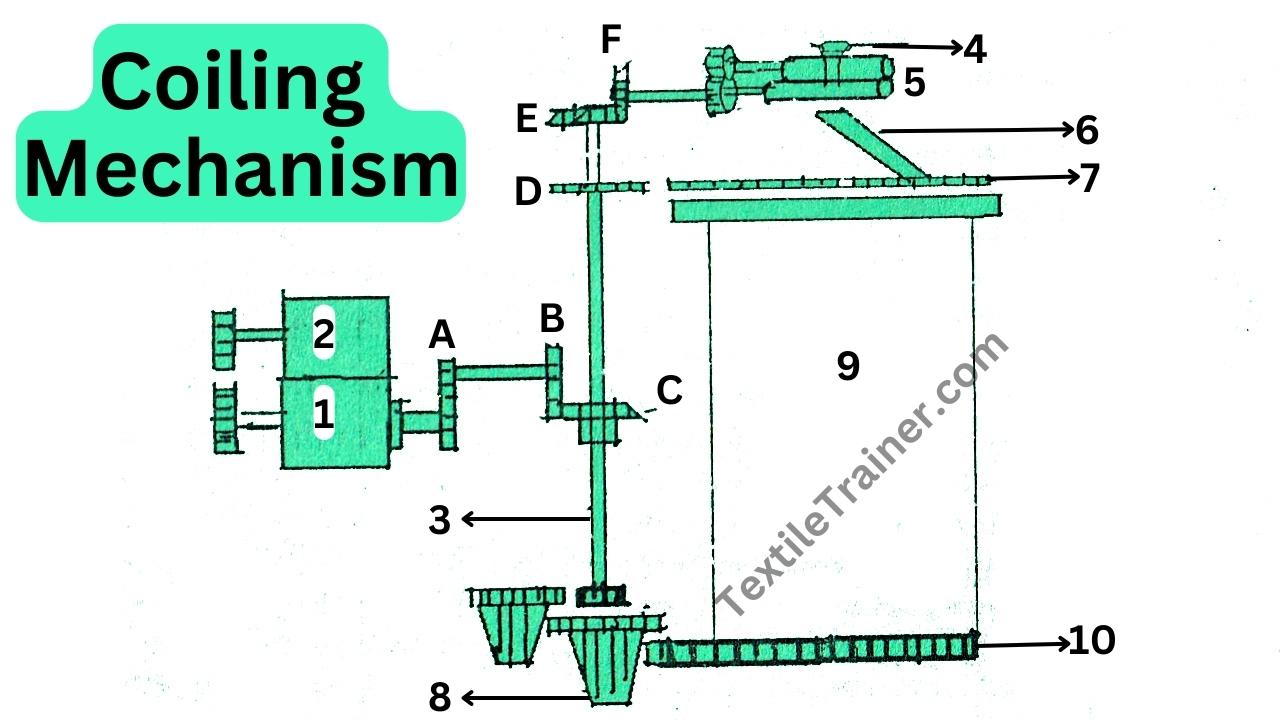

8. Chute feed:

In a conventional system, Scutcher forms a lap to supply material to the cards. But in modern blow room lines, a chute feed system is used. The chute feed system is a continuous process. Chute feed system has the advantages of higher productivity and low variation in the quality of feed materials.

9. Carding:

the process by which the reduction of entangled mass of fibers of filmy web by working them between two closely spaced relatively moving surfaces closed with sharp points is called carding. There two proverbs of the experts-

“The card is the heart of the spinning” and “well carded is half spun”

10. Drawing:

Drawing is a process in which the sliver is blended, doubled, leveled, and drafted by passing the sliver through a series of pairs of rollers, each pair moving faster than the previous one is called drawing. The main object of the drawing frame is to straighten the crimped and hooked fibers in the card slivers. In the drawing process, paralyzation of the fibers along the sliver axis so that when they come to be spun on the spinning frame, they will be evenly drafted and twisted to produce good quality yarn.

11. Lap Former:

For making combed yarn, a former lap machine is used. The former lap machine converts the drawn sliver into the lap. The lap is obtained by doubling a certain number of draw slivers. Usually, 16 to 32-draw sliver is used to make a lap.

12. Comber:

The combing process is used to make combed yarn. This process involves straightening and parallelizing the fibers and removing short fibers impurities by using a comb. The main object of combing is to remove the fiber shorter than a predetermined length, remove remaining impurities in the pre-comber lap, and remove neps. As a result, a uniform sliver is produced.

13. Simplex or roving or speed frame:

Roving frame converted the combed sliver or, in some cases, draw the sliver into roving. In the roving frame, insert a small amount of twist to give the required strength of roving. Transforming the sliver into roving occurs continuously through three stages: drafting, twisting, and winding.

14. Ring Frame:

This is the final stage of spinning. This machine achieves the goal of this manufacturing process to get yarn. The ring frame converts the roving into yarn. There are different types of spinning machine is used. But the ring frame is a conventional spinning machine. The rotor spinning system is a modern spinning system.

15. Auto coner:

The size of the spinning bobbins is very small. The auto corner is used to transfer yarn to the large package needed for efficiency at weaving and knitting. Auto coner is a modern winding system. With this machine, we can produce a large cone without any knot. All types of faults of yarn, such as thick places, color materials, etc., are cleaned by this machine. This machine can lubricate the knitted yarn.

16. Heat Setting:

Heat setting changes the strength, dye-ability, and softness of the year. It is done in one kind of chamber. The chamber is heated to about 600C by steam. The yarn package is heated for about 40 to 50 min. Heat setting also sets the yarn twist.

17. Packing:

After the heat setting, yarn cones are packed in polythene paper in a cartoon with a certain number, normally 24 cones of 2.08 kg each for knitted yarn. Finally, cartoons are shifted to the weaving section or buyer.

References

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L.B graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning . Dhaka: Granthanir Prokashoni.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

- The_Rieter_Manual_of_Spinning_vol._2_1922 v3_83522_Original__English__83522