Introduction:

Most important 50 terminologies used in merchandising process with abbreviations is described in this article simply. The person who is involved in managing the buyers and their orders by taking card of the garments business in an apparel industry is called merchandiser. in general, the merchandisers or the merchandising activity in an apparel industry can be classified into three broad categories.

- Fashion merchandisers.

- Product merchandisers.

- Retail merchandisers.

Terminologies Used in Merchandising Process:

It is essential to understand and know the meaning of a few terminologies used in merchandising process. Every merchandiser have to know these terminologies used in merchandising process with abbreviations. This will help beginners to understand the process quickly. The important terminologies used in merchandising process are as follows:

1. Accessories:

A range of products that are designed to accompany items of clothing to complete an overall look. They are usually intended to be decorative. Common examples include ties, belts, bags, scarves, hats and jewelry.

2. Base fabric:

All fabric, woven and knitted, needs to be approved for quality before it is used in garment construction. Fashion buyers give approval at two different stages referred to as “base” and “bulk” fabric approval. In order for a fabric to be committed for further development, it must be approved for stability and suitability for end use.

3.Bulk fabric:

Refers to the completed fabric that is used in the make-up of garments. The fabric dyed to a specific color, will often contain printed designs and possess certain “finishes” which provide it with specific benefits.

4. Buyer:

A buyer for a fashion retail brand will be involved in a more complex buying process involving design, sourcing and production.

5. Buying team:

The team of individuals that is responsible for planning and buying a specific range of merchandise within a fashion company. Usually, it consists of a buyer and merchandiser, together with their individual support staff. The buying team is normally responsible for a specific product or garment, but sometimes the team may be responsible for a range of items.

6. Forecast:

A view of where the business will be in the future based on the best-known historical and current information. This method can be used to predict subjective issues like fashion trends, but it is most commonly used to predict sales or stock levels ahead of time. Forecasting is a regular merchandising task that helps to ensure that the business has the right balance and level of stock delivered in readiness for anticipated sales.

7. Forward buying:

Relates to the process of buying ahead to meet anticipated future sales and stock levels. Forward buying is highly dependent on how long it takes a buyer from conception to delivery to make a purchase.

8. Hanging stock:

Most garments delivered to a fashion business arrive from the manufacturer on hangers. This enables them to be immediately put out on the sales floor. This eases handling when delivering to the distribution center and then on to the shop. The advantage of this method is that it reduces garment creasing, which is common with boxed deliveries.

9. Inventory:

A detailed list of stock or goods held. Sometimes the word “inventory” is used instead of “stock”.

10. Lead-time:

The period of time from design conception to delivery to retail stores. The definition of lead time may vary according to the particular stage in the supply chain which is being considered. For example, some buyers may refer to a manufacturing-to-store delivery lead time, while others may refer to the shipping lead time.

11. Mark-down/Mark-up:

Price movement may be downwards or upwards. Generally, fashion businesses adjust prices regularly to ensure stock sells out at the planned rate. Price reductions encourage slow-selling goods to sell more quickly, while price increases slow the rate of sale. Throughout the course of the season/year, fashion businesses keep track of all markdowns and makeups. This information is generally expressed as a percentage.

12. Silhouette:

The outline shape of a garment.

13. Visual merchandising:

The creative display of goods in-store and in windows. Historically, the term was specifically associated with window displays. Atmospherics and visual marketing using sound and interactive technology have increased the overall sophistication of visual merchandising

14. UPC:

Universal Product Code – Standard for encoding a set of spaces that can be scanned and interpreted into numbers to identify a product. A sequence of numbers and a bar code on the back of each product.

15. OOS:

Abbreviation for Out of Stock: item not available for sale at this time.

16. SKU:

Abbreviation for stock keeping unit. Some SKU’s have more than one facing. On a planogram(POG), each SKU represents a different product and is a number assigned by the retailer to identify the product’s type, colour, and size.

17. UOM:

Abbreviation for unit of measurement.

18. Reserve stock:

Merchandise that is stored in an area inaccessible by customers.

19. Teck pack:

Commonly known as technical specification sheet or order information sheet or speec. Sheet. It is the collected data of a particular order with a full detailed description of that order. Merchandisers develop these details or receive them from buyers.

20. category:

sometimes called as “product group”, it is used to group together garments or similar lines into one group. Fashion retailers can quickly see how a group of lines is performing as a whole. It helps monitor sales performance as well as control stock levels.

21. CIF:

Carriage, Insurance, and Freight: The term refers to the agreement on the delivery of foreign goods that is included within the cost price. The cost price paid by the buyer includes transport or merchandise by vessel to a country specified by the buyer. It is up to the seller to arrange insurance and delivery of the merchandise within the price they agree.

22. CMT:

“Cut, Make and Trim”. Generally used in the production of more complex or tailored garments, in which a clothing manufacturer receives fabric belonging to the retailer or another party to make up into a finished garment. During the process, you pay only for the cutting, making up, and provision of items to trim the garment.

23 Colour way:

A colour option of a product style.

24. COO:

Country of Origin: Most products have the country in which they were manufactured recorded on a label attached to the garment. This is not, however, a legal requirement in the United Kingdom and most European countries.

25. Cost price:

The price paid for a product before a mark-up is added to achieve a selling price. As a general rule, the cost price of a fashion product bought for resale by a retailer includes all tickets, hangers, protective covers and packaging. Transport to the retailer is typically included in the cost price.

26. Couture:

Derived from the French word for “dress-making”, it generally refers to extremely individual and unique hand-made garments made in the studios and workrooms of international high fashion designers.

27. Designer:

A person who is involved in a creative process, turning customer needs into value outcomes. Outcomes may range widely according to the specific role of the designer, but could include manufactured products, corporate logos or packaging.

28. Distribution centre (DC):

A facility which redistributes products to retail outlets having received them as deliveries from suppliers.

29. Fit:

Refers to the suitability of the shape and size of a garment to a person. It primarily focuses on comfort and appearance, although fashion trends can have a significant impact on the former.

30. Fit model:

A model, usually a size 12 in women’s wear, who tries on fit samples in order that garment technologists and buyers can make appropriate adjustments to prototype garments as part of the quality control process.

31. FOB

Free on Board: This is a cost-price term which does not include complete delivery to the buyer in the cost price. Deliveries to a port in the country of manufacture are included in the cost price. Subsequent insurance and transportation of the merchandise from the port to the final destination is the buyer’s responsibility. Many fashion retailers prefer to use FOB as they can control the cost and lead times associated with shipping to their country.

32. Bill of Lading:

A bill of loading describes the conditions of a contract between the exporter/shipper and the logistic company to move fright at a specified charge between stated points.

33. Cutting Order:

A cutting order is a document used by a company to maintain the cut and to produce a specific number of garments.

34. CM:

CM is the cost of making a garment. This can include trimmings, cutting, making, trimming costs, time spent making, etc. CM is a term that refers to the commercial components of garment merchandising.

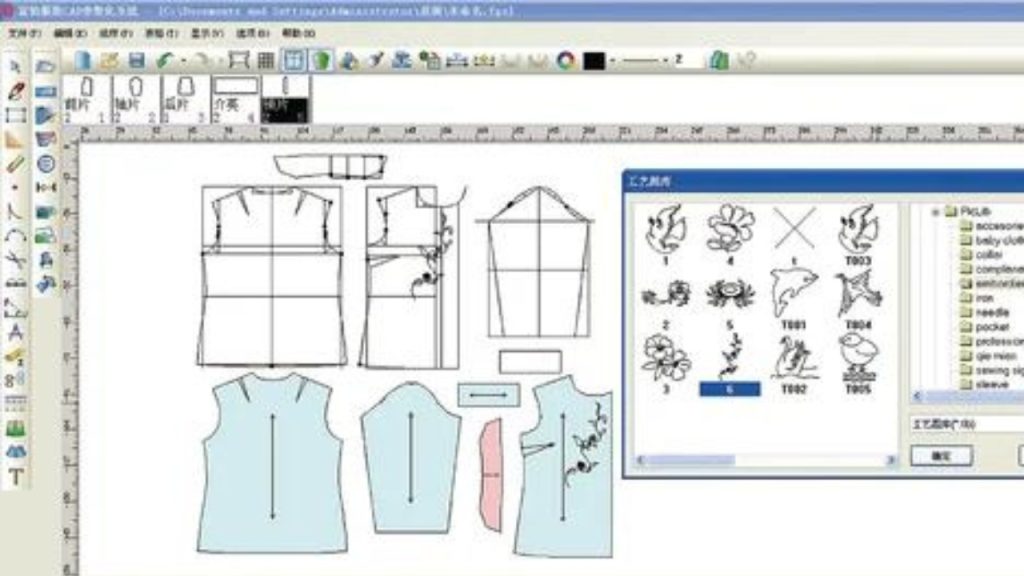

35. CAD:

Computer Aided Design (CAD) can be used as a theoretical tool for designing and developing garment products. When it comes to cutting fabric in the garment industry, CAD refers to fabric cutting.

36. Cut-off-date:

A cut-off date is the date by which a shipping line accepts packed goods for a particular vessel. Usually it is 5-8 days prior to the actual ship moving day.

37. Dummy:

The dummy is an artificial human body that is used for measuring garment fittings using the actual human body shape.

38. Grading:

Grading is the process of increasing or decreasing the size of a sample pattern in order to constitute a complete size range.

39. Gross Margin:

The difference between net sales and net costs of merchandise/product during a given time period is known as gross margin.

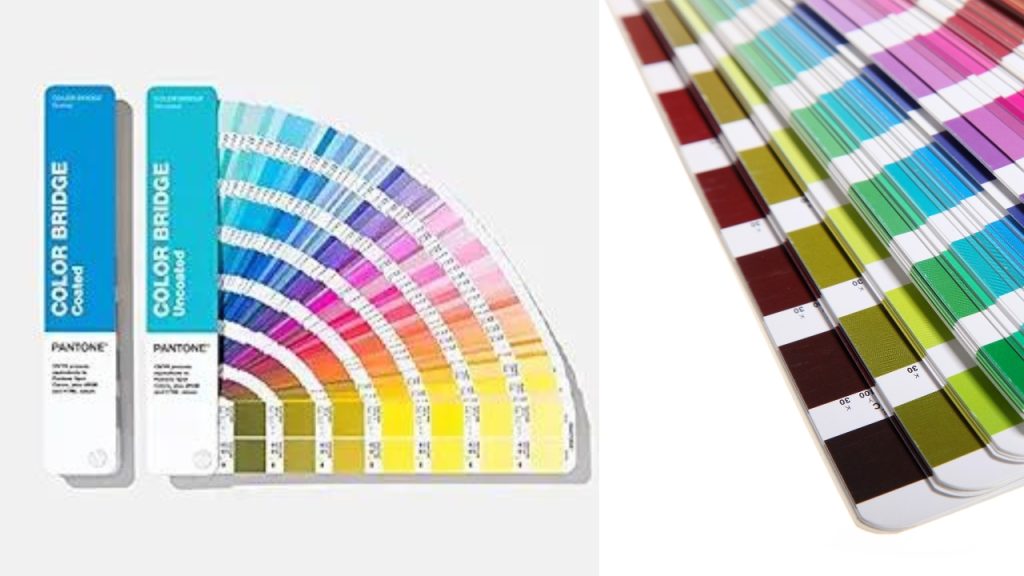

40. Lab dip:

To check color standards given by Pantone, the merchandiser has to prepare 4-5 lab dip options for each color. This swatch is dyed in the laboratory of the mill for accuracy.

41. L/C:

L/C stands for letter of credit, which is given by the buyer via his bank. In a normal sense, L/C could be defined as an order provided by the buyer to the manufacturer, stating all the terms and conditions.

42. Line Balancing:

A line balancing plan is used to maintain a smooth production schedule based on the time and action calendar. It is also used in the garment sewing floor to ensure timely completion of orders.

43. Partial Shipment:

As long as the buyer has given us permission to ship the first half of the goods, we can ship the first half, and then ship the remaining goods. This is known as a partial shipment, or a partial shipment with a delay.

44. Pantone:

It is a universal shade color shade card used in all industries for dye-to-match (DTM). Each color has a six-digit number. Pantone works with TP (take-pads) and TC (take cards).

45. Pattern:

The pattern is a hard thick paper that is used to get the actual shape of a garment. It can also be used for guiding a marker.

46. SMV:

The Standard Minute Value (SMV) is an important topic on a garments sewing floor. The Standard Minute Value has something to do with garments time studies.

47. Strike-off:

Merchandisers send strike-off samples to buyers for approval before printing or embroidering. For approval, merchandisers send buyers trail samples made by printers or computerized embroidery.

48. Time and Action Calendar:

A TNA is a short form of Time and Action Calendar, also referred to as an issuing schedule, production schedule or time and action plan. In order execution process, TNA is referred to as a short form of Time and Action Plan.

49. Thread Run:

The thread run is an important term in sewing. The thread used to stitch a garment and its color are known as the thread run.

50. Yarn Dips:

A yarn dip is the same procedure as a lab dip. If a fabric is a yarn dyed check or strip, the yarns are dyed in the laboratory, and the merchandiser sends the dyed yarns to the buyer for color approval.