Introduction:

Polyester/cotton blended fabric dyeing process is complex. Because cotton and polyester are two different fibers that come from natural sources and are synthetically produced consecutively. These two fibers have different physical characteristics, such as length, diameter, strength, elasticity, torsional rigidity, frictional properties, and chemical properties, such as thermal properties, density, resistance to chemical agents. Cotton is very resistant to alkalis, but aqueous alkalis can seriously damage polyester. Polyester should not be pressure boiled in alkalis, as this speeds up the deteriorating process. Terylene fiber is fully alkali resistant for its purpose as a textile fiber. The alkali sensitivity of polyester/cotton blends should be considered when scouring them. The polyester/cotton blends with more cotton require more scouring and bleaching agents in pretreatment because cotton fibers hold more dirt and impurities than polyester fibers. The purpose of this article is to explain how to calculate dyeing recipes for polyester and cotton blend fabric.

In this case, we will be using a two-stage method using a single bath. We generally use this method for dyeing knits and yarns for dyeing machines such as winches, jets, beams, or package dyeing machines. According to this method, the polyester part of the material is dyed first with disperse dyes, after which the cotton part of the material is dyed with reactive dyes.

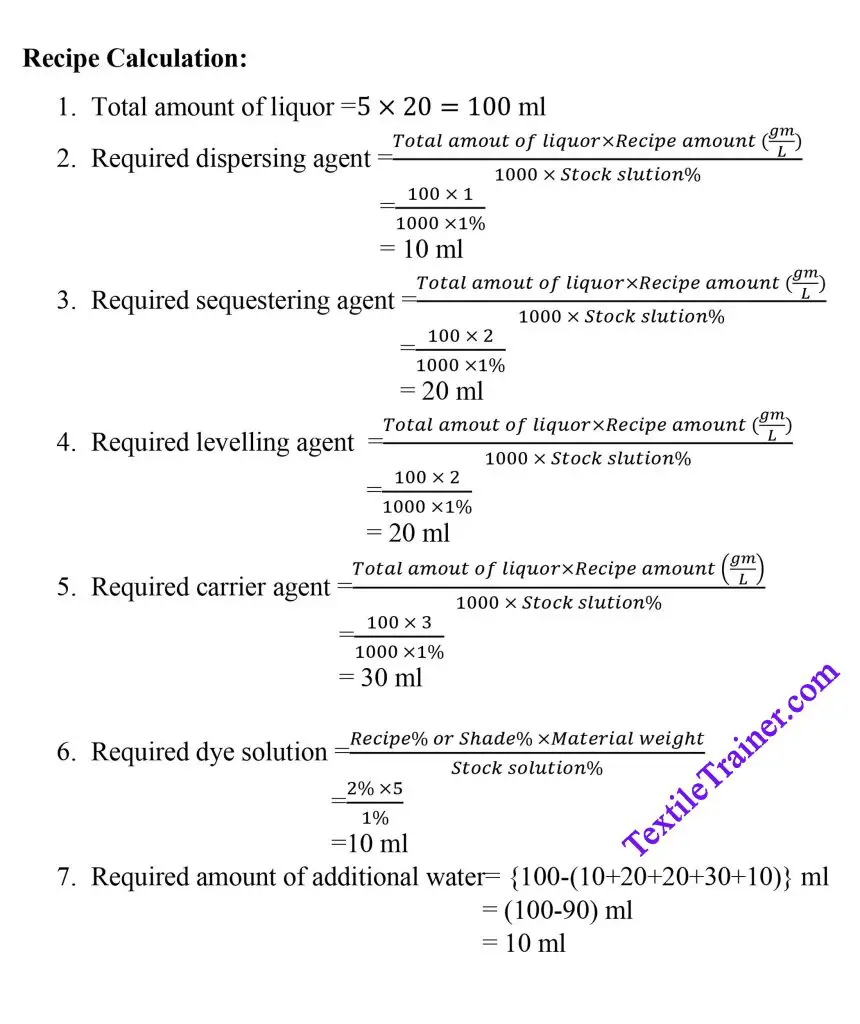

Typical recipe for polyester part:

| Chemical name | Recipe amount |

| Dispersing agent | 1 gm/L (Stock Solution 1%) |

| Sequestering agent | 2 gm/L (Stock Solution 1%) |

| Levelling agent | 2 gm/L (Stock Solution 1%) |

| Carrier | 3 gm/L (Stock Solution 1%) |

| Acetic acid | 2 gm/L ( to maintain pH=4-5) |

| Disperse dyes(Yellow) | 2% (Stock Solution 1%) |

| Temperature | 130-1350 C |

| Time | 30-60 mins |

| M:L | 1:20 |

| Sample weight | 5 gm |

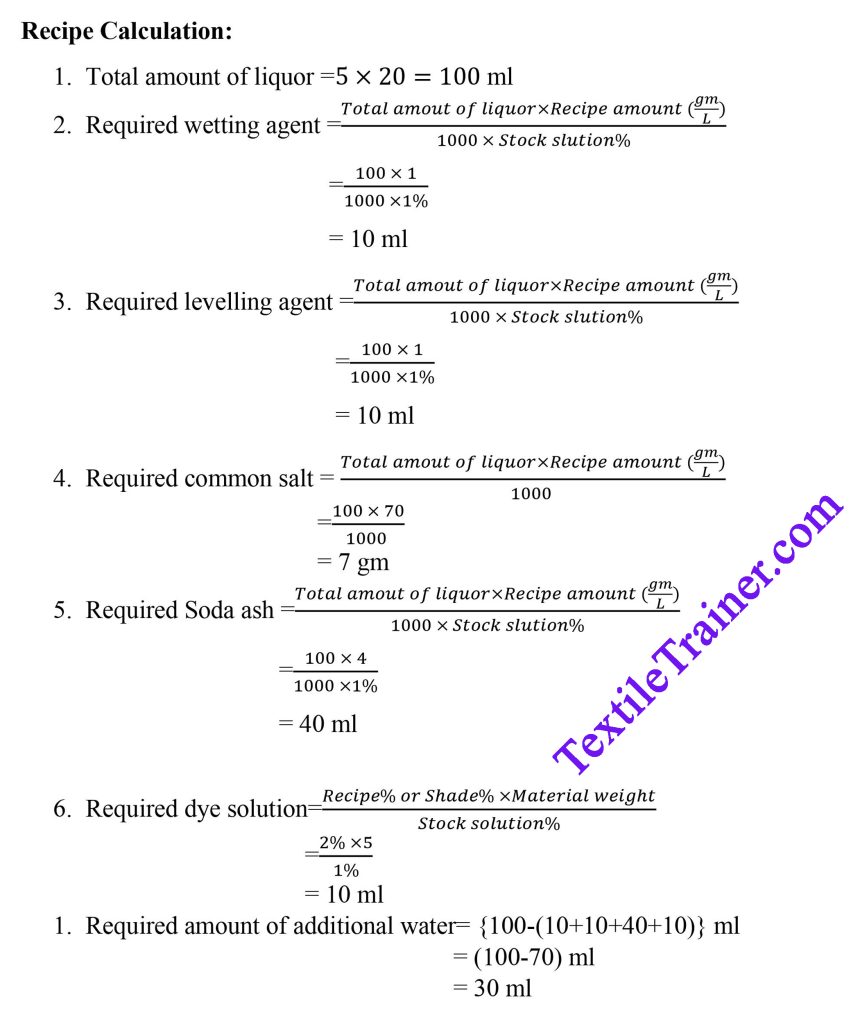

Typical recipe for cotton part:

| Chemical name | Recipe amount |

| Wetting agent | 1 gm/L (Stock Solution 1%) |

| Levelling agent | 1 gm/L (Stock Solution 1%) |

| Common salt | 70 gm/L |

| Soda ash | 4 gm/L (Stock Solution 1%) |

| Reactive dye(Yellow) | 2% (Stock Solution 1%) |

| Temperature | 50-600 C |

| Time | 30-50 min |

| pH | 10.5±0.5 |

| M:L | 1:20 |

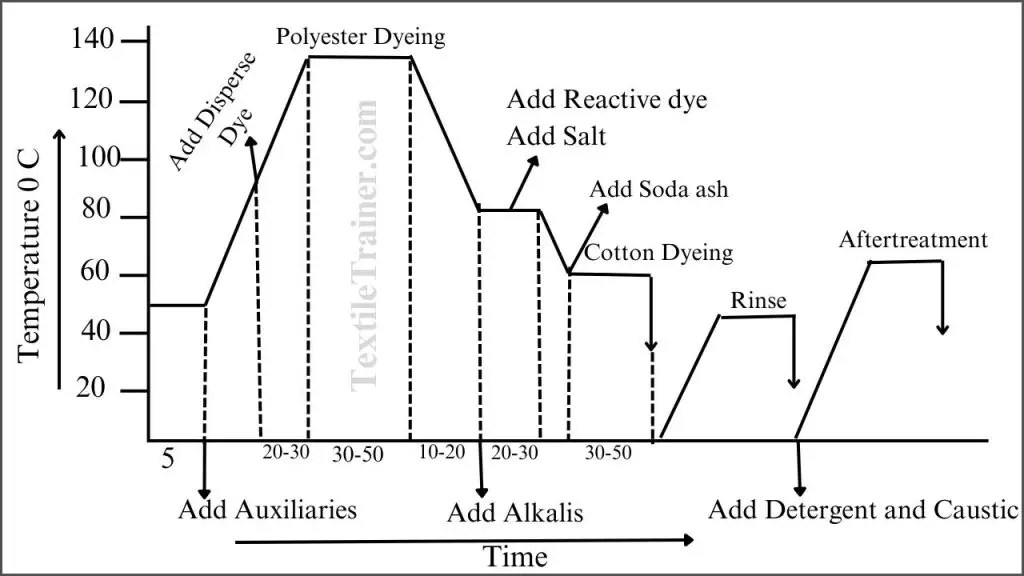

Blended Fabric Dyeing Procedure:

Dyeing Curve 01: Polyester/cotton blend fabric dyeing curve

- A dyebath with substrate should be set at 50°C temperature, then the dispersing agent, acetic acid (pH around 4-5), as well as other auxiliaries should be added, and then the dyebath should be run for 5-10 minutes.

- A dye solution of disperse dyes should be added and the temperature should be raised to 70-80°C.

- As a next step, increase the temperature from 800 C to 130-1350 C

- The bath should be run at the same temperature for 30-60 minutes.

- To neutralize the pH of the bath, lower the temperature down to 80-900 degrees Celsius over a period of 10-20 minutes using alkalis.

- As a final step, add the reactive dyes and salt to the dye bath according to the recipe, and let it run for 20-30 minutes.

- As soon as the temperature is lowered to 600 C, the alkalis (Soda Ash ) should be added and the dye will be run for 30-60 minutes for the cotton parts to be dyed.

- Drop the dyebath and proceed with the after-treatment process after dropping the dyebath.

After treatment process:

In order to improve colorfastness, it is very important to wash and clean properly in order to remove all dyes that are not yet fixed to the fabric. After polyester dyeing, the unfixed disperse dyes are removed by alkalis due to their action on the unfixed dyes. As a final step, the after treatment process is carried out as described in the recipe below.

| Chemical name | Amount |

| Detergent | 3 gm/L |

| Caustic | 3 gm/L |

| Time | 15-30 min |

| Temperature | 70-800 |

- Rinse twice with hot and cold water successively.

- Then treat the fabric with mentioned above recipe

- Rinse hot and cold wash successively.

- Then dyer the sample.

- Finally check the shade.

Final Result:

Here is the final result of our sample

You should participate in a contest for one of the best blogs on the web. I’ll recommend this web site!

thank you……please share my article…..

It’s best to participate in a contest for among the finest blogs on the web. I will suggest this web site!

thank you…..please share my post

There are some interesting deadlines on this article however I don抰 know if I see all of them heart to heart. There may be some validity but I will take maintain opinion until I look into it further. Good article , thanks and we want extra! Added to FeedBurner as effectively

thank you….please share my article in your social media

After examine a number of of the weblog posts in your website now, and I truly like your method of blogging. I bookmarked it to my bookmark web site list and can be checking back soon. Pls take a look at my web site as effectively and let me know what you think.

thank you….please share my article…..

Very neat article post. Awesome.