Introduction

In the garment industry, especially in apparel merchandising, trouser fabric consumption computation is extensively used in calculating garment consumption. There is no doubt that merchandisers have a very important role in this regard. Also, if the trouser fabric consumption calculation is incorrect, the company will face a considerable loss, and its reputation will suffer. The trouser is one of the most commonly produced particulars in the apparel industry, and they are also used daily in the garment industry. Calculating trouser fabric consumption for an order is one of the most important tasks for a merchandiser to perform. In the event that the final consumption of an order needs to be more accurate, then the manufacturer will also be faced with a huge problem and could lose the trust of its customers. The consumption determination of fabric is an important term in the cloth sector when calculating trouser fabric consumption for an order. As it depends on the fabric prices, accurate and efficient fabric consumption will help reduce the amount of fabric wasted, thereby allowing for the production of trousers at a reasonable price. Therefore, we should understand how the fabric is adequately consumed to keep proper records.

Important of Fabric Consumption Calculation

Fabric consumption calculation is an essential aspect of garment manufacturing that plays a crucial role in the success of the clothing business. It refers to determining the fabric needed to make a particular garment, including allowances for wastage, shrinkage, and pattern matching. Accurate fabric consumption calculation helps optimize the use of raw materials, reduce production costs, and minimize fabric wastage. It enables manufacturers to plan their production processes effectively, order the right amount of fabric, and avoid overproduction or underproduction. Moreover, fabric consumption calculation is critical in ensuring consistency in the size and fit of garments. The fabric required for a specific garment may vary depending on the design, size, and style. By calculating the correct fabric consumption, manufacturers can ensure that each garment has the same amount of fabric, resulting in consistent sizing across different sizes.

Below are some important points that need to be taken into consideration

- Fabric consumption calculation helps optimize the use of raw materials, reduce production costs, and minimize fabric wastage.

- Accurate calculation ensures that the right amount of fabric is ordered and used for each garment, avoiding overproduction or underproduction.

- It helps manufacturers plan their production processes effectively and ensure that there is enough fabric available to complete the order.

- Proper calculation of fabric consumption is critical in ensuring consistent sizing and fit of garments, regardless of their design, size, or style.

- Incorrect fabric consumption calculation can lead to significant losses in terms of time, money, and resources, as well as affect the quality and consistency of the finished products.

- By using computer-aided design (CAD) software, manufacturers can accurately calculate fabric consumption and minimize the risk of errors or miscalculations.

- Fabric consumption calculation is especially important in mass production, where a small difference in fabric usage can have a significant impact on overall production costs and profits.

- The calculation also helps in determining the selling price of the garment and ensuring that it is competitive in the market.

Apparatus for Consumption

- Woven fabric.

- Scissor

- Measuring tape.

- Shape card.

- Calculator

- Tailoring clack.

- Scale

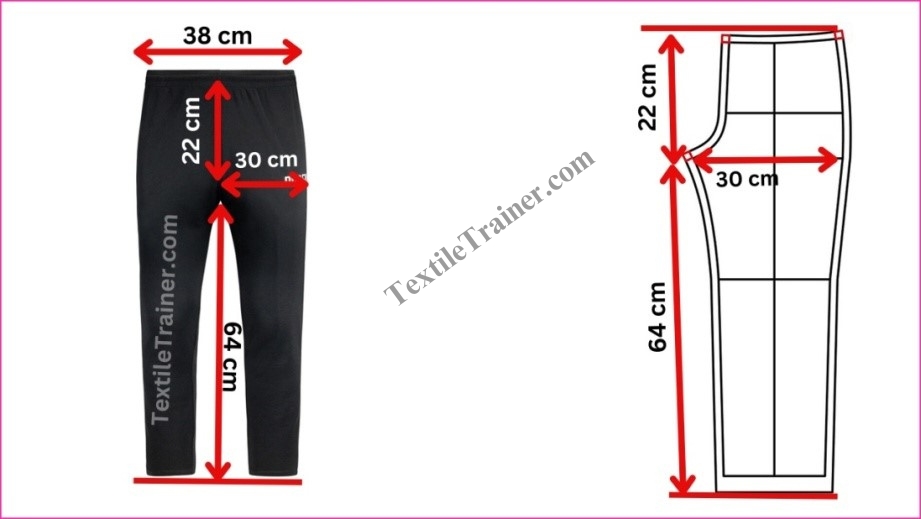

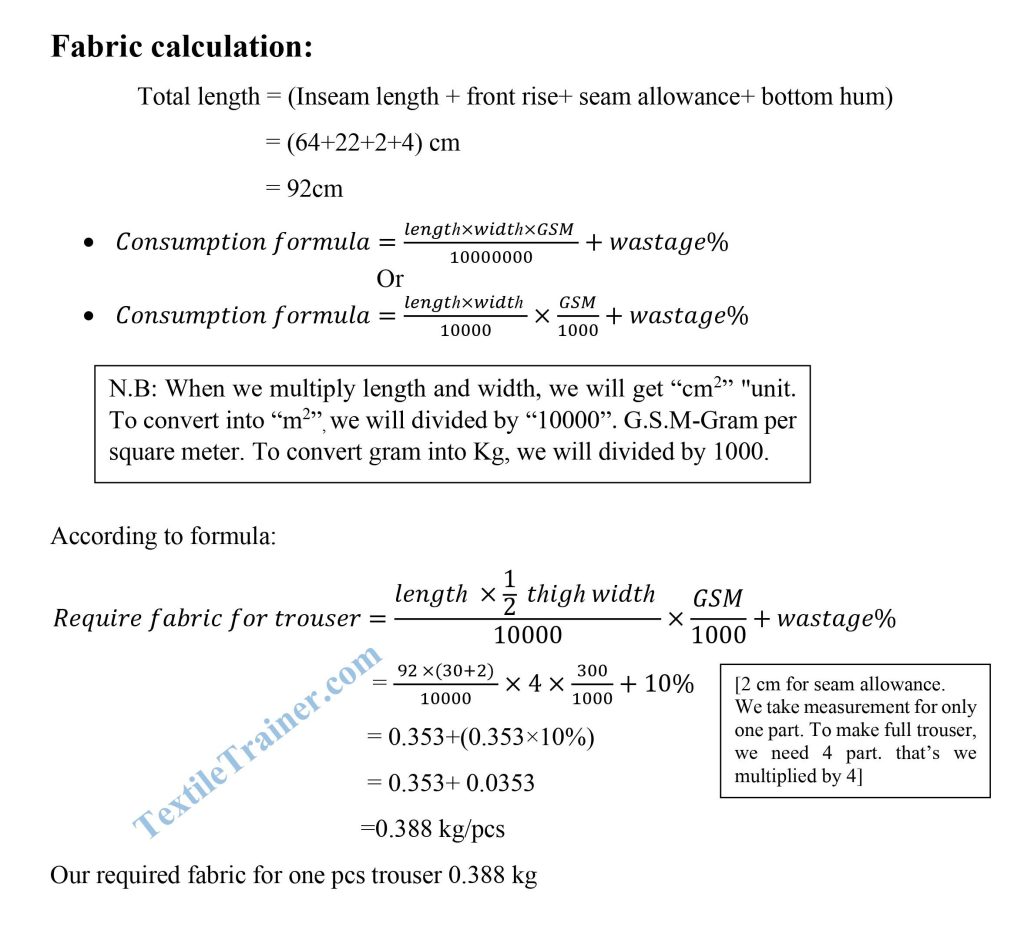

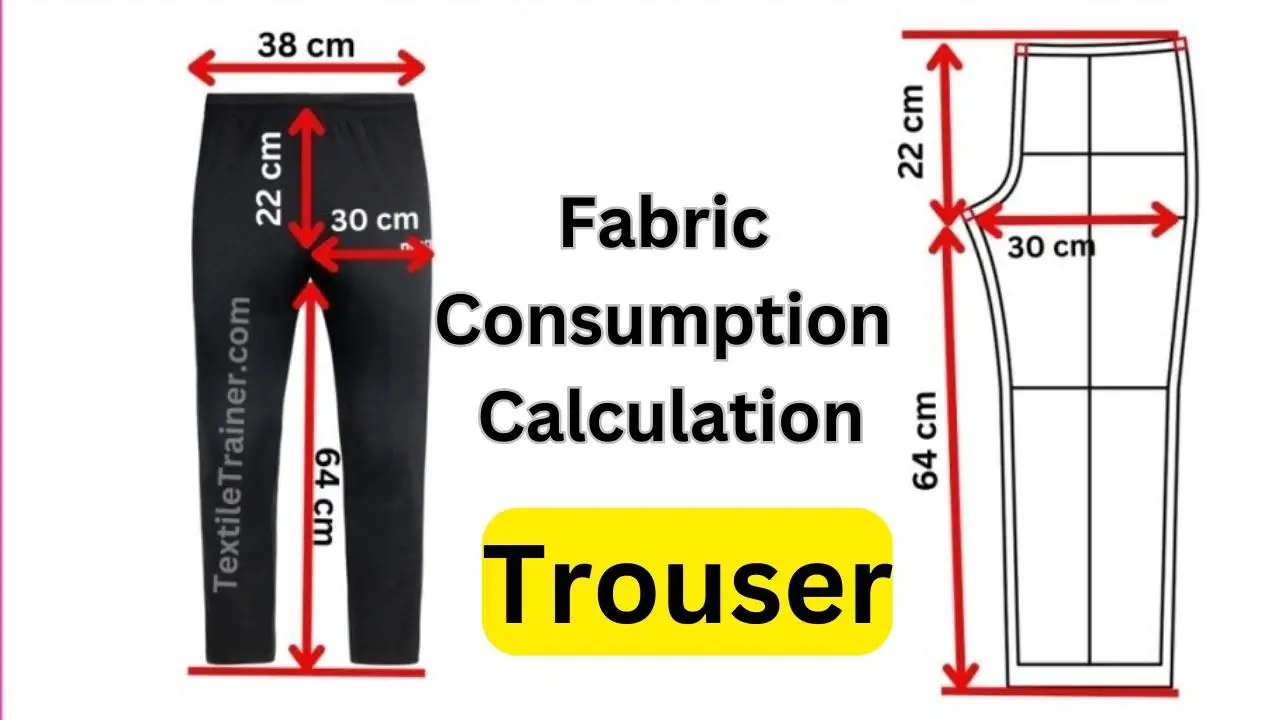

Measurement sheet:

| S/N | Description | Measurement |

| 1. | ½ waist circular | 38 cm |

| 2. | Front rise | 22 cm |

| 3. | ½ thigh | 30 cm |

| 4. | Inseam length | 64 cm |

| 5. | Fabric GSM | 300 |

Conclusion:

Fabric consumption calculation is an essential aspect of garment manufacturing that plays a crucial role in the success of the clothing business. It refers to determining the fabric needed to make a particular garment, including allowances for wastage, shrinkage, and pattern matching. Accurate fabric consumption calculation helps optimize the use of raw materials, reduce production costs, and minimize fabric wastage. It enables manufacturers to plan their production processes effectively, order the right amount of fabric, and avoid overproduction or underproduction. Moreover, fabric consumption calculation is critical in ensuring consistency in the size and fit of garments. The fabric required for a specific garment may vary depending on the design, size, and style. By calculating the correct fabric consumption, manufacturers can ensure that each garment has the same amount of fabric, resulting in consistent sizing across different sizes.

I think this is a real great blog. Great.

thanks for comments.

I really like and appreciate your article post.Really looking forward to read more. Keep writing.

thanks…

Thank you for your post.Really thank you!

keep visit our site….

Really informative blog article.Really thank you!

thanks too. please support us.

I am so grateful for your blog post.Really looking forward to read more. Keep writing.

keep visit our site…

fantastic points altogether, you simply gained a emblem new reader. What might you recommend about your submit that you simply made some days in the past? Any certain?

I’ll immediately grab your rss feed as I can’t find your email subscription link or newsletter service. Do you have any? Kindly let me know so that I could subscribe. Thanks.

Okay

Thank you dear. Stay with us. Happy reading.

I really liked your blog post.Really thank you! Keep writing.

keep visit our site..

Major thanks for the post.Really looking forward to read more. Fantastic.

please support us.

I loved your article.Really looking forward to read more. Really Great.

please support us….

I truly appreciate this article post.Really looking forward to read more. Really Great.

Thank you, I’ve just been looking for info approximately this subject for a while and yours is the greatest I’ve discovered till now. However, what concerning the bottom line? Are you positive in regards to the source?

Hello! Do you know if they make any plugins to assistwith Search Engine Optimization? I’m trying to get my blogto rank for some targeted keywords but I’m not seeing very good results.If you know of any please share. Thank you!

This is a very good tip particularly to those new to the blogosphere. Simple but very accurate infoÖ Thank you for sharing this one. A must read article!

I’d like to order some foreign currency can imodium get you high Interesting…But I have yet to see a study that examines the whole matter from the view point of the growing segment of the population that has left the workforce…The “babyboomers”

Oh my goodness! Incredible article dude! Many thanks, However I am having difficulties with your RSS. I donít know why I cannot join it. Is there anyone else having the same RSS issues? Anybody who knows the solution can you kindly respond? Thanx!!

fantastic points altogether, you just received a new reader.What would you recommend about your post that you just made afew days ago? Any positive?

What’s Going down i am new to this, I stumbled upon this I have found It absolutely useful and it has helped me out loads. I hope to give a contribution & help different customers like its helped me. Good job.

Some truly good information, Sword lily I discovered this. «A poem is never finished, only abandoned.» by Paul Valery.

I’m not sure where you are getting your info, but great topic. I needs to spend some time learning much more or understanding more. Thanks for wonderful info I was looking for this info for my mission.

Thanks , I have recently been searching for info about this subject for ages and yours is the greatest I’ve discovered so far. But, what about the conclusion? Are you sure about the source?

Thanks too

What’s Going down i’m new to this, I stumbled upon this I’ve discovered It positively useful and it has aided me out loads. I hope to give a contribution & help other users like its helped me. Good job.

Thanks

Really informative blog post.Really looking forward to read more. Awesome.

Say, you got a nice post.Thanks Again. Will read on…

I loved your article post.

I really like and appreciate your article.Much thanks again.

Actually when someone doesn’t know after that its up to other viewers that theywill help, so here it happens.

thank you.

I loved your blog post. Awesome.

Very good article post.Really looking forward to read more. Great.

A round of applause for your blog post. Much obliged.

This paragraph is really a nice one it helps new net people,who are wishing in favor of blogging.

I really liked your blog article. Want more.Loading…

A round of applause for your post.Thanks Again. Cool.

Major thankies for the article.Really thank you! Will read on…

thanks too..

Im grateful for the article post. Great.

I really like and appreciate your article post.Much thanks again. Really Great.

Major thanks for the blog post.Much thanks again. Fantastic.

I love what you guys are usually up too. Such clever work and reporting! Keep up the fantastic works guys I’ve incorporated you guys to my blogroll.

Dieses Buch kann einen gro?en Unterschied darin machen, wie wir miteinander, mit uns selbst und mit den gro?en Freuden der Welt umgehen

Thanks a lot for the blog article.Really thank you! Keep writing.

I really like and appreciate your blog post.Really thank you! Really Great.

Im grateful for the blog.Thanks Again.

Very neat article post.Thanks Again. Will read on…

Thank you for your article.Really thank you! Keep writing.

Say, you got a nice article post.Thanks Again. Will read on…

I think this is a real great article post. Keep writing.

I appreciate you sharing this blog article.Thanks Again. Awesome.

WOW just what I was searching for. Came here by searching for saturn

Fantastic blog post.Really looking forward to read more. Much obliged.

I loved your article. Want more.

Major thanks for the post.Really looking forward to read more.

Thank you for your article.Really thank you! Much obliged.

Thanks again for the blog.Really thank you!

I really liked your blog post. Cool.

Say, you got a nice article.Thanks Again. Really Great.

Very neat blog post.Really thank you!

I think this is a real great blog post.Really looking forward to read more. Will read on…

I value the article.Much thanks again. Keep writing.

Enjoyed every bit of your blog.Really thank you! Will read on…

Great, thanks for sharing this blog. Awesome.

Fantastic blog article.Thanks Again. Cool.

I really liked your article.Much thanks again. Much obliged.

Very neat blog. Awesome.

Really enjoyed this article post.Really looking forward to read more. Keep writing.

Really enjoyed this blog post.Really looking forward to read more. Much obliged.

Thanks for sharing, this is a fantastic post.Really thank you! Awesome.

This is one awesome post.Thanks Again. Will read on…

Thanks so much for the article post.Thanks Again. Keep writing.

I cannot thank you enough for the post.Really looking forward to read more. Much obliged.

Now I am ready to do my breakfast, later than having my breakfast coming yet again toread more news.

Im grateful for the article.Thanks Again. Really Great.

Great, thanks for sharing this article post.Thanks Again. Great.

Really enjoyed this blog article.Much thanks again. Want more.

Im grateful for the blog article.Really looking forward to read more. Fantastic.

A round of applause for your blog article. Will read on…

Fantastic blog post.Thanks Again. Really Great.

Great blog article. Keep writing.

Very good blog article.Thanks Again. Will read on…

A round of applause for your blog.Much thanks again. Much obliged.

Thanks so much for the article post.Really thank you! Cool.

A big thank you for your post. Awesome.

Say, you got a nice article post.Really thank you! Awesome.

This is one awesome blog post.Much thanks again. Awesome.

Very neat blog article. Cool.

Great blog.Much thanks again. Really Cool.

This was an excellent article. I loved it. I’ll be back to see more. Thank you !

Major thanks for the blog.Really thank you! Keep writing.

Im grateful for the article.Much thanks again. Really Great.

Appreciate you sharing, great blog post.Thanks Again. Much obliged.

Appreciate you sharing, great blog.Really thank you! Great.

Enjoyed every bit of your blog post. Really Great.

I think this is a real great post. Really Great.

Thanks again for the blog.Much thanks again. Keep writing.

I truly appreciate this article post.Really looking forward to read more. Want more.

Very neat blog.Really thank you! Really Cool.

Awesome blog post.Really looking forward to read more. Keep writing.

Fantastic article post.Really looking forward to read more. Keep writing.

I think this is a real great blog article.Thanks Again. Great.

Thank you for your blog article. Really Great.

I value the blog article.Thanks Again. Keep writing.

I loved your blog post.Really looking forward to read more. Much obliged.

I value the blog.Really looking forward to read more. Great.

Thanks so much for the article.Really thank you! Much obliged.

I think this is a real great post.Thanks Again. Cool.

Im grateful for the blog post.Really thank you! Want more.

I cannot thank you enough for the blog article. Really Cool.

I truly appreciate this post. Will read on…

Looking forward to reading more. Great post.Really thank you!

I truly appreciate this blog post.Really thank you! Fantastic.

Thank you ever so for you article post.Much thanks again.

I think this is a real great blog.Much thanks again. Much obliged.

A big thank you for your blog article.Thanks Again. Fantastic.

I value the article post.Really thank you! Fantastic.

I really liked your post.Much thanks again. Fantastic.

Thanks for sharing, this is a fantastic article post.

wow, awesome article post.Thanks Again. Really Great.

Really enjoyed this blog post.Thanks Again. Want more.

Im grateful for the article.Much thanks again. Really Cool.

Great article.Really thank you!

I really enjoy the article.Really looking forward to read more. Want more.

I loved your blog article.Really thank you! Cool.

Im grateful for the article post.Really looking forward to read more. Fantastic.

I am so grateful for your blog. Keep writing.

Wow, great article post. Awesome.

I will immediately grab your rss feed as I can not to find your email subscription hyperlink or e-newsletter service. Do you’ve any? Kindly let me know in order that I may just subscribe. Thanks.

I am so grateful for your article.Really looking forward to read more. Cool.

wonderful points altogether, you simply won a new reader.What would you recommend in regards to your put up that you made a few days ago?Any sure?

Thanks

I have read so many articles or reviews regarding the bloggerlovers except this article is truly a nice post, keep it up.

I am so grateful for your post.Really thank you! Much obliged.

I truly appreciate this blog post. Much obliged.

wow, awesome article post.Thanks Again. Cool.

Wow, great blog article.Really looking forward to read more. Will read on…

I value the blog article.Thanks Again. Want more.

Thank you ever so for you blog. Really Cool.

Hi there, this weekend is nice designed for me, because this momenti am reading this enormous informative post here at my residence.

Really appreciate you sharing this blog article. Fantastic.

Thanks

Aloha! Interesting post! I’m really enjoy this.

This is one awesome article post.Thanks Again. Really Great.

Really informative article post.Really thank you!

Looking forward to reading more. Great article post. Will read on…

Im grateful for the blog.Thanks Again. Awesome.

Thanks for the blog article.Really thank you! Great.

Hey, thanks for the article.Thanks Again. Cool.

Thank you for your blog post. Fantastic.

I value the blog article.Much thanks again. Really Great.

Very good blog.Really thank you! Will read on…

Very informative blog article. Really Great.

I appreciate you sharing this article post. Will read on…

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Thank you ever so for you article. Really Great.

Looking forward to reading more. Great article post.Thanks Again. Much obliged.

wow, awesome blog article. Will read on…

Thank you for your blog.Really looking forward to read more. Really Great.

Thanks so much for the blog.Thanks Again. Much obliged.

Really informative post.Really thank you!

Major thanks for the post.Thanks Again. Fantastic.

I appreciate you sharing this post.Thanks Again. Cool.

I really liked your blog post.Much thanks again. Really Great.

wow, awesome article post. Will read on…

I think this is a real great post.Really thank you! Awesome.