Introduction:

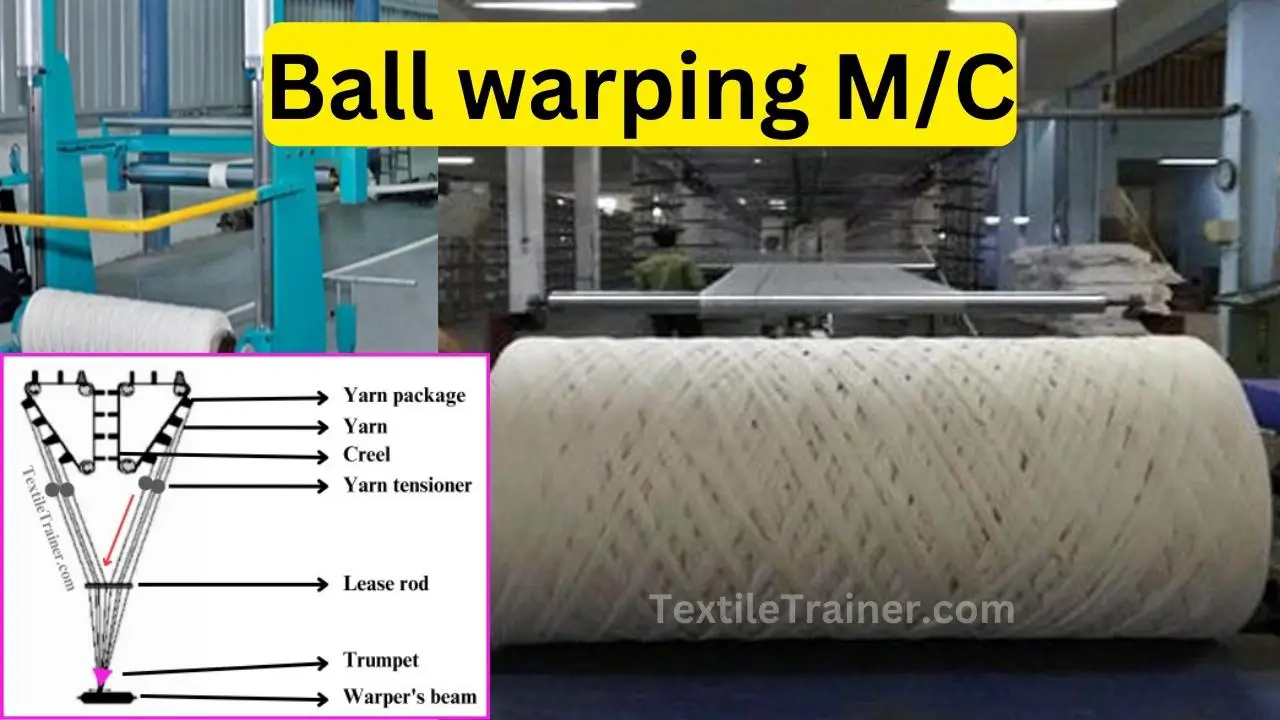

Ball warping machine is used in denim factory to make rope form of warp yarn. Warp yarns are wound on ball beams as tows when dyed in indigo. The tows are separated and wound back on the beam following the dyeing process. A lease comb and collecting reed are usually used to achieve tangle-free lease insertion. The yarn sheets are combined into ropes during this process. In the manufacturing process of denim fabric, ball warping plays an essential role in preparing yarns for indigo dyeing and achieving the iconic diagonal twill pattern. As part of the process, high-quality yarns are selected, typically made from cotton or cotton-polyester blends, based on the desired characteristics of the finished denim fabric. Creels, frames with multiple parallel rows of pegs, are then used to mount these yarns. As each yarn end is threaded through a peg, exact alignment, and tension are maintained. After the yarns are creeled, they undergo tensioning to ensure uniform tension throughout the system. This step is crucial for ensuring consistent yarn feed in subsequent processes. In a ball warping machine, yarns are fed into rotating cylindrical packages known as ball warps. In order to form a compact cylindrical package, each yarn end is positioned side-by-side on the ball warp.

The main objective of ball warping is to prepare the log for the rope dyeing machine. Here magazine-type creels are used to creele yarns in cheese form. The number of ends is taken for each process to prepare the weaver beam, according to the number of ends in each group. The relevant creeling is performed according to the number of ends in each group to make the required number of logs for the rope dyeing machine. There are generally 12830 meters of rope on the log, and the sheet of yarn passes through a lease reed where leases are inserted, denting the long chain beams. A lease is inserted regularly on the machine, generally every 100 meters. The lease also helps in yarn separation after sizing.

Objectives of ball warping:

- Ball warping prepares warp yarns for indigo dyeing by winding them onto a ball beam in the shape of a tow, which maximizes the surface area available for dye penetration.

- This minimizes tangles and snarls in the yarns, preventing interruptions and disruptions during subsequent processes such as indigo dyeing, sizing, and weaving.

- Ball warping produces a tow that must be separated into individual yarns when dyeing indigo. With the ball warping process, yarns are separated and rebeamed onto beams, allowing for smoother and more efficient handling in subsequent stages of manufacture.

- The ball warping process ensures uniform tension between the warp yarns, which ensures stability and evenness during the dyeing, sizing, and weaving processes, resulting in high-quality denim fabric.

- Denim fabrics are more consistent and controlled with ball warping. The process ensures that the warp yarns are evenly wound onto the ball beam so the final fabric has a uniform yarn distribution. As a result, manufacturers are able to meet customer specifications and maintain consistent product quality.

In summary, the objectives of ball warping in denim fabric manufacturing include improving dye penetration, strengthening and structuring yarn, improving yarn handling efficiency, and ensuring consistency and quality control throughout the production process. Together, these objectives help achieve the desired aesthetics and characteristics of high-quality denim fabrics.

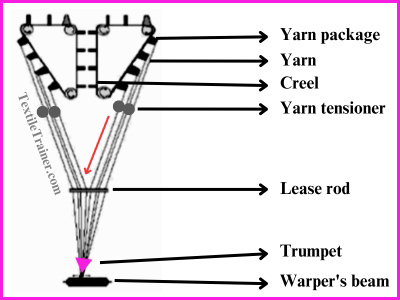

Passage of yarn through the ball warping machine:

Working principle of ball warping machine:

- The first step in ball warping involves the removal of 350 to 500 yarn ends from the creel. In the ball warping process, magazine-type creels are used.

- After that, the warp yarns are passed through the tension device. Tension devices are crucial in achieving uniform tensions in the warp yarns during the ball warping process. As the yarns are fed into the ball warping machine, these devices are designed to control and regulate their tension while they are being fed.

- In the next step, the warp yarns are passed through what looks like a comb-like device (reed), which keeps the warp yarns parallel to one another and separate from one another.

- The lease string is placed across the sheet of warp yarns at intervals of every 1000 to 2000 yards in order to aid the separation of the yarns in the warp sheet.

- In order to pull the sheet of yarn into rope form, the yarns have to go through a funnel-shaped device, called a condenser or trumpet, that collapses and condenses the sheet of yarn into rope.

- As soon as the rope is ready, it is wound up onto a long cylinder called a log with the help of a machine known as a ball warper.

Advantage of ball warping:

- In ball warping, the dye liquor penetrates the yarns better. By winding the yarns into a compact cylindrical package, the dye liquor is exposed to more surface area. By doing so, dyes are more efficiently and uniformly absorbed, resulting in fabrics that are richer and more evenly colored.

- By aligning the warp yarns in parallel, ball warping helped achieve the characteristic diagonal twill pattern and desired denim fabric appearance. In subsequent weaving processes, it ensures an even and consistent distribution of yarns.

- When yarns are wound onto a ball beam, tangles and snarls in the yarns are minimized, which improves production efficiency and minimizes waste by reducing the likelihood of yarn breakage during subsequent processes such as indigo dyeing, sizing, and weaving.

- The ball warping process enables efficient handling of the warp yarns. The wound yarns on the ball beam are easily transported, stored, and fed into subsequent machinery without tangling or excessive tension. Therefore, smooth operations are facilitated, and productivity is increased.

Disadvantage of ball warping:

- Manufacturers with limited factory space may find it challenging to accommodate ball warping machinery because they need a certain amount of floor space.

- In order to achieve optimal results, ball warping machinery needs to be properly setup, operated, and maintained. This is a specialized process that requires technical expertise. In order to effectively handle the equipment, training and skilled personnel may be required.

- A small-scale or budget-limited manufacturer may find it challenging to afford the initial investment in specialized machinery and equipment required to implement ball warping in denim manufacturing.

- A ball warping process requires expertise and careful attention to detail. In order to ensure proper operation and maintenance, additional training and resources may be required because of the complexity of the process, which entails specific machinery, tensioning devices, and lease insertion tools.

Conclusion:

It is important to consider the advantages and disadvantages of ball warping when manufacturing denim fabrics. Improving dye penetration, enhancing yarn alignment, and reducing yarn breakage is a crucial pre-indigo dyeing steps. It produces a higher quality fabric with fewer defects because it contributes to the overall quality of the yarns. In addition to providing flexibility in yarn selection, ball warping can accommodate a wide variety of yarn types and blends.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- banerjee, N. (2000). Weaving Mechanism. West Bengal: Smt. Tandra Banerjee and Sri Apurba Banerjee.

- Belal, P. D. (2016). Understanding Textiles for a Merchandiser. Dhaka: LB Graphics & Printing.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Rahman, M. M. (2008). Fabric Manufacturing Technology. Dhaka: Books Fair Publications.

- V. Gordeev, P. V. (1982). Cotton Weaving. Russia: Mir Publishers Moscow.

I appreciate you sharing this blog post.Really thank you! Will read on…

Thank you……..

Appreciate you sharing, great blog post.Really thank you! Really Cool.

keep visit our site…

Great article post.Really thank you! Keep writing.

Keep visit our site….

Hey, thanks for the blog post.Really thank you! Awesome.

Keep visit our site….

A big thank you for your article post.Thanks Again. Will read on…

keep visit our site…..

Very good blog.Thanks Again. Want more.

I will try….

Thanks again for the blog post.Really thank you!

thanks too. please support us.

Very good blog.Really thank you! Awesome.

keep visit our site. thanks too.

Fantastic article post.Really looking forward to read more. Keep writing.

keep visit our site…

I really like and appreciate your blog article.Thanks Again. Want more.

Thanks

I really liked your blog post.Thanks Again. Will read on…

Thanks

I think this is a real great blog.Thanks Again. Great.

This is one awesome article.Much thanks again. Cool.

thanks….

Really informative blog post.Much thanks again. Will read on…

Awesome article.Really looking forward to read more. Really Cool.

wow, awesome blog.Thanks Again. Much obliged.

Really enjoyed this blog post.Really looking forward to read more. Will read on…

Awesome post. Keep writing.

Great article. Great.

Say, you got a nice post.Much thanks again. Fantastic.

wow, awesome blog.Thanks Again. Really Cool.

Thanks too……

Thank you for your blog article.Really looking forward to read more. Really Great.

Fantastic blog. Want more.

I appreciate you sharing this post. Awesome.

thanks too…..

I am so grateful for your blog post.Really looking forward to read more. Great.

A round of applause for your blog article.Thanks Again. Really Great.

wow, awesome article post.Really looking forward to read more. Want more.

Thanks

Great blog article. Fantastic.

Im obliged for the blog post.Really looking forward to read more. Really Cool.

Thanks again for the article.Thanks Again. Cool.

I really enjoy the blog. Great.

Awesome blog article.Much thanks again. Much obliged.

A big thank you for your blog article.Really looking forward to read more. Fantastic.

Really appreciate you sharing this blog.Really thank you!

Thanks for sharing, this is a fantastic article. Keep writing.

Im obliged for the article post.Much thanks again. Really Cool.

Thanks so much for the post.Much thanks again. Want more.

Thanks for the article post.Thanks Again. Much obliged.

Thanks a lot for the article post. Want more.

Im thankful for the article.Much thanks again. Will read on…

wow, awesome blog.Much thanks again. Cool.

Very informative article post.Thanks Again. Will read on…

Really appreciate you sharing this article post.Much thanks again. Really Great.

Appreciate you sharing, great article. Much obliged.

I really liked your blog.Really looking forward to read more. Awesome.

Thanks a lot for the blog post.Really looking forward to read more. Will read on…

I really enjoy the blog post.Really looking forward to read more.

Thank you ever so for you blog article.Thanks Again. Awesome.

Really informative blog article.Really thank you! Keep writing.

Very good blog article.Thanks Again. Want more.

A round of applause for your blog post.Really looking forward to read more. Want more.

Thanks for sharing, this is a fantastic post.Much thanks again. Really Great.

Very neat blog.Really thank you! Cool.

Wow, great article post.Really looking forward to read more. Really Great.

wow, awesome blog.Really thank you! Really Cool.

Hey, thanks for the post. Will read on…

I am so grateful for your article.Thanks Again. Cool.

I really liked your post.Really looking forward to read more. Want more.

I really like and appreciate your blog article. Will read on…

I loved your blog post. Want more.

Really appreciate you sharing this blog. Will read on…

Say, you got a nice blog post.Much thanks again. Cool.

Say, you got a nice blog.Really thank you! Will read on…

Really enjoyed this article.Thanks Again. Want more.

Fantastic article post.Much thanks again. Great.

I really enjoy the post.Much thanks again. Really Great.

Fantastic blog post.Thanks Again. Really Great.

I value the blog.Really looking forward to read more.

Thank you ever so for you article post.Really thank you! Fantastic.

Thanks a lot for the article. Really Great.

I really like and appreciate your blog article.Really looking forward to read more. Cool.

I am so grateful for your blog article.Really thank you! Will read on…

Hey, thanks for the blog.Thanks Again. Really Great.

Thanks again for the article.Really looking forward to read more. Fantastic.

I really like and appreciate your blog.Really looking forward to read more. Really Great.

I value the article post.Really thank you! Want more.

Thanks again for the article.Really thank you! Really Great.

wow, awesome article.Thanks Again. Really Great.

I am so grateful for your blog post.Really thank you! Keep writing.

Really appreciate you sharing this blog article. Much obliged.

Thank you ever so for you article post.Much thanks again. Want more.

I think this is a real great post.Really thank you! Want more.

I loved your blog article.Much thanks again. Really Great.

Say, you got a nice blog post.Thanks Again. Keep writing.

Really informative article post.Really looking forward to read more. Much obliged.

A big thank you for your article. Great.

Major thanks for the blog.Really looking forward to read more. Awesome.

A round of applause for your blog post.Really thank you! Fantastic.

Fantastic post.Thanks Again. Awesome.

Very neat blog article. Really Cool.

I think this is a real great article post.Really thank you!

Major thankies for the article post.Thanks Again. Want more.

Appreciate you sharing, great post.Thanks Again. Cool.

A big thank you for your blog article.Really thank you! Will read on…

Thanks for the post.Really thank you! Will read on…

Thanks so much for the post.Thanks Again. Fantastic.

I appreciate you sharing this post. Much obliged.

Awesome post. Want more.

I really liked your blog post.Much thanks again. Really Cool.

Thanks again for the post. Want more.

Thanks so much for the blog post.Really looking forward to read more. Keep writing.

Very informative blog article. Really Great.

Great post.Much thanks again. Fantastic.

I loved your blog article.Really thank you! Fantastic.

Very informative article.Really looking forward to read more. Want more.

Very good blog article.Thanks Again. Really Cool.

Thank you for your blog.Thanks Again. Want more.

Thanks for the blog.Thanks Again. Really Great.

Thanks again for the blog post.Thanks Again. Keep writing.

Great, thanks for sharing this blog article.Thanks Again. Really Great.

Awesome article.Really thank you! Much obliged.

Hey, thanks for the article post.Thanks Again. Fantastic.

Really enjoyed this blog.Really thank you!

Thanks for sharing, this is a fantastic blog article.Thanks Again. Fantastic.

Welcome stay connected

Very informative article.Really looking forward to read more. Want more.

Great blog article.Thanks Again. Cool.

Really appreciate you sharing this article.Thanks Again. Keep writing.

Great, thanks for sharing this article post.Thanks Again. Much obliged.

Very informative post.Thanks Again. Will read on…

I really liked your blog article.Really thank you! Keep writing.

Thanks again for the article post.Really thank you! Much obliged.

Thank you ever so for you blog post. Will read on…

Really informative blog. Great.

Really informative blog.Really looking forward to read more. Awesome.

Thanks for sharing, this is a fantastic article post.Thanks Again. Really Great.

Looking forward to reading more. Great blog post.Much thanks again. Much obliged.

Thanks a lot for the blog.Really looking forward to read more. Fantastic.

Thank you for your blog article.Really looking forward to read more. Keep writing.

Enjoyed every bit of your article. Cool.

I really like and appreciate your blog article.Really looking forward to read more. Awesome.

This is one awesome blog.Much thanks again. Much obliged.

Thanks for sharing, this is a fantastic blog article. Fantastic.

I am so grateful for your article.Really thank you! Awesome.

I really like and appreciate your blog.Really thank you! Want more.

Thanks for sharing, this is a fantastic article post. Want more.

Great article post.Much thanks again. Really Great.

Say, you got a nice post. Much obliged.

Major thanks for the post.Much thanks again. Fantastic.

I am so grateful for your blog post.Thanks Again. Cool.

Im grateful for the article post.Really looking forward to read more. Keep writing.

Really enjoyed this blog article. Fantastic.

Say, you got a nice blog article.Thanks Again. Great.

Really enjoyed this article post.Thanks Again. Great.