Lea Strength Tester for Yarn Strength: Explained Step-by-Step

Lea Strength Tester for Yarn Strength: Explained Step-by-Step

Introduction:

Tensile strength is defined as the force or load per unit area required to rupture a material. The textile industry uses many different units throughout the world to express strength. The strength of both spin and continuous filament yarns is not described as pounds per square inch. It is more acceptable to use other measurements, such as:

- Lea strength or skein strength.

- Count-strength product.

- Single strand strength.

- Tenacity.

- Breaking length

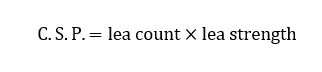

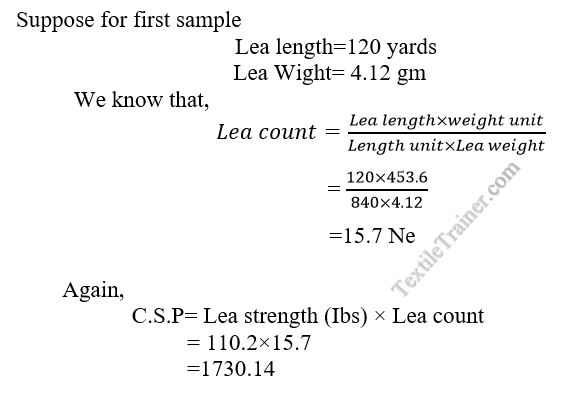

In many sections of the textile industry, strength testing is still carried out in lea or skein. The strength of the yarn is in the skein form, which is made up of 80 wraps of yarn totaling. Another is related strength is C.S.P. C.S.P. refers count strength product. When we multiply the product of the braking load in pounds of a lea of yarn with its count, then found C.S.P. Mathematically, C.S.P. express as:

The yarn having more C.S.P. is better than the yarn having lower C.S.P. for the same count of yarn.

Objectives:

- To know about lea strength tester.

- Come to learn how to calculate C.S.P.

- To know to how to make lea or skein.

- To know working procedure of lea strength tester.

Apparatus:

- Lea strength tester.

- Wrap reel.

- Electrical balance.

- Cotton yarn.

The test must, of course, be on conditioned fabric and be made in a standard testing atmosphere.

Standard testing temperature:

An atmosphere at the prevailing barometric pressure with a relative humidity of 65% and temperature of 200 C is called standard testing temperature.

Procedure for preparation of lea or skein:

- Place the supply package in the creel of the reel and place the yarn through the proper tension devices.

- Attach yarn to the reel under the holder provided for this purpose.

- Adjust tension devices to give proper tension as previously outlined.

- Set yardage indicator or automatic knock-off motion for power-driven reels.

- Now start to wind lea or skein.

6. Cut or break yarn from the supply package and tie the ends of the skeins together so that the skein is bound together. The knot should be secured so the skein will be held together but not bound at the knot.

7. Remove the skein from the reel. This can be facilitated on most power-driven reels by collapsing one or more arms of the reel.

8. After making the lea, weigh the lea to measure the lea count.

We will prepare 5 leas in the same way to calculate avg: strength and C.S.P.

Working Procedure:

- In the lea strength tester, the prepared lea to be subjected to a tensile load is placed between the two jaws, J1 and J2.

- After placement of lea in the machine, we will press the ON button of the machine.

- As the load increases gradually, the lea gets broken when the load reaches to breaking point.

- We will observe the monitor until the lea is torn out.

- The machine will be stopped when the lea is torn out.

- From the monitor, we will get lea strength.

- After calculating the lea count, calculate the C.S.P of the lea.

The rest lea will be tested in the same way mentioned above procedure. Then will calculate the average strength and C.S.P of the lea.

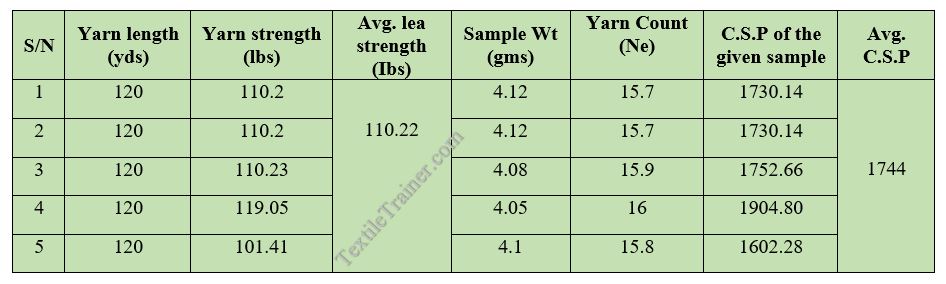

Calculation for Yarn Strength:

Final result

- Avg. strength of yarn=110.22 (Ibs)

- Avg. C.S.P=1744

Conclusion:

When yarn having C.S.P less than 1800 are bad and between 1800-2200 are average and greater than 2200 are strong. From our experiment, we found C.S.P. of our yarn is 1744 which is bad quality. However, from this experiment we learned how to making lea. we also learned about lea strength tester and how to calculation of C.S.P. This experiment will help in our future work place. Thanks to our teacher to help us.

References:

- Booth, J. (2008). Principles of Textile Testing. New Delhi: CBS Publishers & Distributors.

- Hamby, E. B. (1993). Handbook of Textile Test and Quality Control. New York: Wiley Eastern Limited.

- HU, J. (n.d.). Fabric Testing. New York: Woodhead Publicatioing Limited.