Garment Dyeing Process: Explained Advantages & Disadvantages

Introduction

The garment dyeing process is a new technology in the textile industry. In the garment dyeing process, fully sewn garments are dyed instead of fabric. It has lots of advantages as well as a disadvantage. This article will discuss the flow chart of the garment dyeing process, its advantages, and disadvantages. Before going to the main tropics, let’s come to learn what is garment dyeing process??

What is the garment dyeing process?

Garment dyeing is a process of dyeing where fully sewn garments are dyed after they have been constructed. Traditionally, fabric dye before stitching. But, these methods dyed manufactured garments. It is ideal for customized fashion. Some common garments dyed this way such as:

- T-shirts

- Pants

- Hoodies

- Sweaters

- Denim garments.

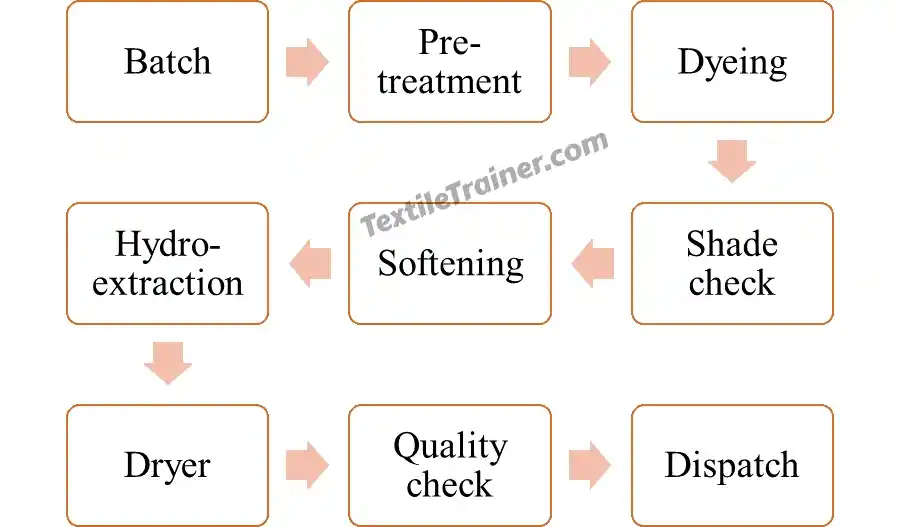

Flow chart of Garment dyeing process

Typical Garment Dyeing Recipe

Generally, following types of dye use in garment dyeing:

- Direct Dye

- Reactive dye

- Pigment dye

- Dischargeable dye

- Sulfur dye

But, this article brief direct dyeing recipe and reactive dyeing recipe

Direct Dyeing Recipe

| Date:……………………………….. Customer name:……… Style:……………………………… Color:…………………………… | Weight: 2 kg Qty:…………………….… Process: Direct dyeing Machine No: 01 | ||||||

| Process | Chemicals | Percentage (OWF) | g/l | Qty (gm) | Temp (0C) | Time | Water (L) |

| Scouring | Dayamul RCLB | 3 | 60 | 80 | 20 | 20 | |

| Caustic soda | 2 | 40 | |||||

| Hydrozen Per oxide | 4 | 80 | |||||

| BSB | 0.1 | 2 | |||||

| BBU 250 | 0.1 | 2 | |||||

| Rinse | 2 times | Cold | 5 | 20 | |||

| Dyeing | Idosoal orange 2GL | 0.125 | 2.5 | Direct heating 900 for 3 min. Direct cooling 650 | check 30-45 min | 20 | |

| Indosol Red BA | 0.45 | 9 | |||||

| Indosol Bark Blue GL | 0.04 | 0.8 | |||||

| Glaubar salt | 3 0 | 600 | |||||

| Rinse | 2 times | Cold | 5 | 20 | |||

| Softening | Cationic | 5 | 100 | 350 | 5 | 20 | |

Reactive Dyeing Recipe

| Date:……………………………….. Customer name:……… Style:……………………………… Color:…………………………… | Weight: 4 kg Qty:…………………….… Process: Reactive dyeing Machine No: 01 | ||||||

| Process | Chemicals | Percentage (OWF) | g/l | Qty (gm) | Temp (0C) | Time | Water (L) |

| Scouring | Scouring agent | 4 | 160 | 80 | 20 | 40 | |

| Caustic soda | 2 | 80 | |||||

| Hydrozen Per oxide | 5 | 200 | |||||

| Rinse | 2 times | Cold | 5 | 40 | |||

| Acid Rinse | Acetic acid | 1 | 40 | 50 | 5 | 40 | |

| Dyeing | Leveling agent | 4 | 160 | Room temperature | 10 | 40 | |

| Discharge reactive turquoise blue | 2 | 80 | |||||

| Glaubar salt | 30 | 1200 | |||||

| Direct heating | 70 | 10 | |||||

| Soda Ash 1st dose | 8 | 320 | 60 | 10 | |||

| Soda ash 2nd dose | 8 | 320 | 60 | 30 | |||

| Direct cooling | 55 | Check 10-15 | |||||

| Rinse | 2 times | Cold | 5 | 40 | |||

| Fixation | Fixing agent | 2 | 80 | 40 | 10 | 40 | |

| Acetic acid | 1 | 40 | |||||

| Neutralization | Sodium meta bi sulfate | 2 | 80 | 40 | 10 | 40 | |

| Softening | Cationic | 6 | 240 | 350 | 5 | 40 | |

| Silicon | 3 | 120 | |||||

Working Procedure of garment dyeing process

- Batch: Initially, garments are separated according to the fabric type, style and required color in the batch section. Basically, garments are prepared for bulking dyeing in a uniform way in the batch section.

- Pre-treatment: This is a process carried out on the garments to remove size material and impurities. The pre-treatment process includes desizing, scouring, and sometimes bleaching. The pre-treatment process improves dye absorption of the fabric.

- Dyeing: The dyeing process is done according to the mentioned recipe. In the case of direct dyeing process, all chemical auxiliaries and dyestuff are added at a time. But, In the case of reactive dyeing process, dyestuff and salt add in the dyeing bath in room temperature. After 10 minutes, add soda ash 1st dose and 2nd dose after 10 min.

- Sade check: Approximately, after 45 minutes, check the shade. If shade is ok. Then go for the subsequent process.

- Softening: Now, dyed garments are treated with softeners. Softeners improve the hand feel as well as proved a smoother finish of the garments.

- Hydro-extraction: after unloading the garments from the machine, garments are sent to the hydro section, which removes excess water from the garments.

- Dryer: Finally, dryer the garments.

Advantage of garments dyeing process

- Garment dyeing process is comparatively lower cost and produce various items in different colors.

- It requires less time to produce and deliver garments.

- As ready made garments are dyed together, there are less risk of shade variation.

- Garments dyeing reducing waste and extending garments life. Because, it is possible to re-dyeing used or faded garments. As a result, it looks fresh, and new appearance.

- The whole process ( de-sizing, scouring, bleaching, and dyeing) can be done in a single machine. So, it helps to streamline operations.

- Setting up a garments dyeing factory is comparatively lower than traditional fabric dyeing setups.

- It helps to reduce the operation cost. As in many cases, garment dyeing uses a lower liquor ratio, which means less water, steam, and chemical usage.

- It also minimized fabric wastage costs. Approximately 15% of the fabric is lost owing to the cutting. Using undyed ( grey) fabric for cutting can save the cost of coloring waste, as well as total overall material expenses.

Disadvantage of garment dyeing process

- It is difficult to dye evenly if garments with mixed fabrics or trims.

- It is not pre-treated properly; some garments may shrink. Which is the cause of measurement issues.

- It is difficult to dying if the fabric contains natural fiber and synthetic fiber.

- 100% cotton garments may get creases at the time of dyeing.

- If seams are too tight or too loose, especially near elastic areas like waistbands or cuffs, is responsible for uneven dyeing.

- Some time damage lycra. Lycra reacts badly with some dyes or bleach.

Garments dyeing Vs fabric dyeing : Key difference

| Feature | Garments dyeing | Fabric dyeing |

| Dyeing stage | Garments dyeing is done after the garments are stitched. | Fabric is dyed before stitching |

| Flexibility | Flexibility is High | Flexibility is Low |

| Shade consistency | It is very consistent across the whole garment. | But, in fabric dyeing may vary slightly between rolls or parts |

| Dye penetration | It can be uneven if not done carefully | It is more even dye penetration across the fabric. |

| Wastage | Less dye is wasted as only the final garments are dyed. | More fabric may be dyed than needed. |

| Chemical and water use | Here, Uses less water, steam, and chemicals in many cases owing to a low liquor ratio. | Generally, Fabric dyeing needs more resources for larger fabric batches. |

| Shrinkage issues | Fabric shrinkage occurs after stitching. So it must be accounted for in the design to keep fit and size. | Fabric is pre-shrunk before cutting, so better fit and size stability. |

| Step up and machinery cost | It Requires lower capital investment and is suitable for small factories or startups | It requires High setup cost and is suitable for large, industrial-scale operations. |

FAQ

Why is garment dyeing a sustainable process?

A sustainable process is a process where less water, chemicals, and energy is used to make a product. With an increasing focus on eco-friendly fashion, many brands are exploring low-water dyeing, natural dyes, and bio-enzyme treatments. In the garment-dyeing process, comparatively less water, less chemicals, and less energy are used. From this angle, garment dyeing is a sustainable process.

What are the steps of garments dyeing process?

There are 8 steps of garments dyeing. They are batch, Pre-treatment, dyeing, shade check, softening, hydro-extractor, dryer, and quality check.

Which types of dyestuff use here?

There are lots of dyestuffs the used in textile industry for fabric dyeing. But, in garment dyeing, specific types of dyestuffs are used including direct dye, reactive dye, sulfur dye, dischargeable dye, and pigment dye.

Conclusion

This article presents the garment-dyeing process with a flow chart and recipe. The recipe is collected from industry and some books. All amount assumption base. However, if you have any problem with this article, let me know in the comments box.

You May Read

- How to Acid Wash Jeans Pant

- Jeans Tie Wash Process with Recipe and Flow Chart

- Top 15 Best Jeans Brands for Women in the World

- Most Common 10 Dry Process in Garments Washing

- Flow Chart of Garments Washing Plant with Easy Description

- Dry & Wet Process Machines in Garments Washing Plan

- All Types of Wet Process in Garments Washing Easy Explanation

- Top 25 Chemicals Used in Washing Plant & Chemical Function