Introduction:

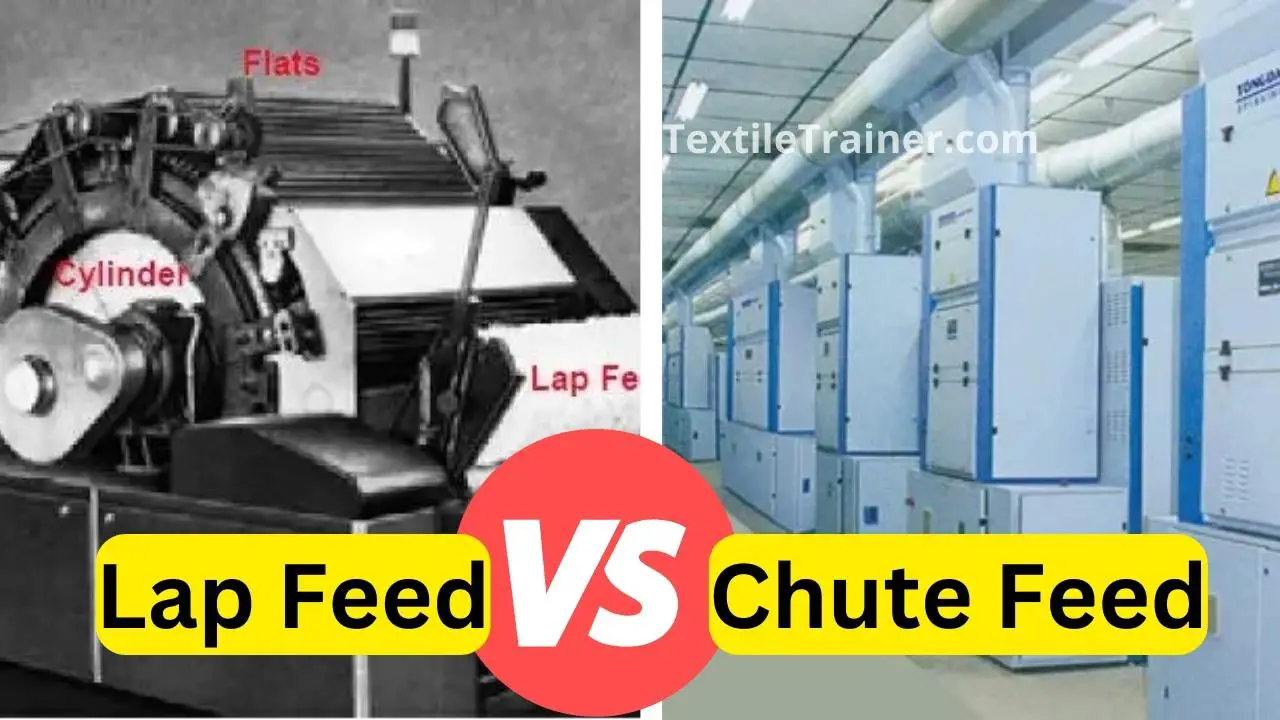

In yarn manufacturing, the feeding system plays a crucial role. It ensures fiber delivery to the carding zone, thereby increasing the efficiency, quality, and productivity of the carding machine. By using advanced technology, textile manufacturers are able to improve the quality of their yarn and increase the efficiency of their production process, thanks to modern feeding systems that offer greater precision and control. There are two types of feed system to carding machine.one is chute feed and other is lap feed system. In this article we will learn differences between chute feed and lap feed system.

- Chute feed system.

- Lap feed system.

Chute Feed System:

A chute feed system is used in modern blow room lines. It is a continuous process. This system can increase productivity and provide better quality feed materials as it is a continuous process.

Lap Feed System:

The lap feed system is used in conventional blow rooms. This is a discontinuous process which has the drawback of being lower in productivity and having a high variation in the quality of the feed material.

Differences Between Chute Feed and Lap Feed System:

| S/N | Parameter | Chute feed system | Lap feed system |

| 01. | Efficiency of blow room | The chute feed system generally offers higher efficiency of blow room. Because, chute feeding allows for continuous and automated fiber transfer system. | Lap feed system generally offers lower efficiency of blow room. Because, in lap feed system no used automated fiber transfer system. |

| 02. | Man power requirement | Chute feeding system requires less man power as it relies on automated process for fiber transfer. | Lap feed system requires more man power as this system involves manual handing lap and manual feed to the carding machine. |

| 03. | Wastage% | The chute feed system tens to have lower wastage% compared to the lap feed system. | The lap feed system may result in higher wastage due to manual handling. |

| 04. | Material Realization | Material realization is higher in the chute feed system. | Material realization is lower in lap feed system. |

| 05. | Degree of carding | Degree of carding is higher. | Degree of carding is lower. |

| 06. | Efficiency of card frame | The chute feed system allows for a higher efficiency of the card frame. | The lap feed system may have a relatively lower efficiency compared to the chute feed system. |

| 07. | Loading on carding rollers | Loading on carding rollers is lower | Loading on carding rollers is higher. |

| 08. | Extra process cost | In chute feed system no need extra process cost. | In lap feed system is need extra process. So here need extra process cost. |

| 09. | Floor space requirement | The chute feed system generally requires less floor space. | The lap fees system may require more floor space. |

| 10. | Quality of card sliver | The cute feed system tens to offer better control over fiber blending and distribution, resulting in more consistent and higher quality card sliver. | The lap feed system may have limitations in achieving optimal fiber blending and distribution. So that quality of card sliver is lower. |

| 11. | Flexibility | The chute feed system offers less flexibility. | The lap feed system is relatively more flexible compared to the chute feed system. |

| 12. | Card production | This system tens to have higher card production rates. | This system may have slightly lower card production rates. |

| 13. | Blending flexibility | Blending flexibility is less | Blending flexibility is more, |

| 14. | Faults | The chute feed system is generally less prone to faults. | The lap feed system is generally more prone to faults. |

| 15. | Utilization of fibers | the chute feed system typically offers better utilization of fibers since there is less waste. | the lap feed system offers less utilization of fibers as fibers waste% is higher in this system. |

Conclusion:

For textile manufacturers, it is crucial to be familiar with the main differences between chute feed systems and lap feed systems in blow rooms. The 15 distinct contrasts outlined in the following analysis shed light on the important factors that influence the choice of feed system in blow rooms. If you have any questions regarding this article, please do not hesitate to contact me.

References:

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L. B Graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Corbman, D. P. (1983). Textiles Fiber to Fabric. NewYork: Mary McGarry.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.