Introduction:

In weaving, warping calculation determines the length, tension, and arrangement of warp yarns on the loom. Achieving accuracy and efficiency in warping is essential for producing high-quality woven fabrics. Here is a guide that will demystify the complexities of warping calculation with easy-to-understand formulas and techniques. This resource will provide a solid foundation for excelling in warping calculation, whether a beginner or an experienced weaver. The guide includes numerous exercises designed to reinforce your understanding and application of the concepts. These exercises give you the opportunity to practice calculations and develop your warping skills. The ability to master warping calculation will enable you to ensure accurate warp length, proper tension distribution, and optimal yarn placement on the loom, resulting in improved fabric quality, reduced material waste, and improved weaving efficiency. This guide will help you take control of the warping process, resulting in greater creativity, productivity, and success in your weaving endeavors, whether you are weaving for personal projects or a professional textile business.

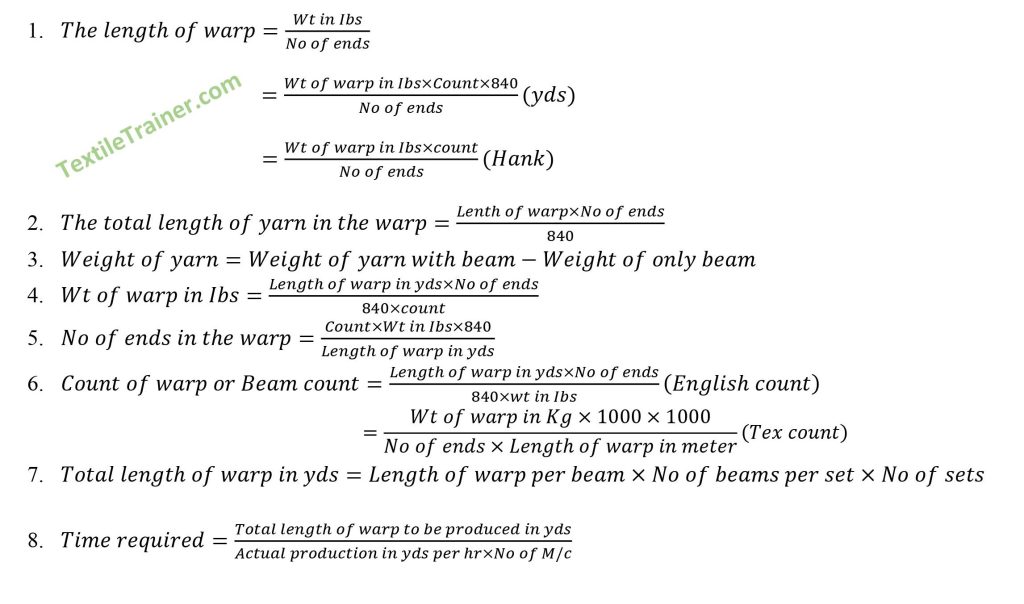

Required Formulas for Warping Calculation:

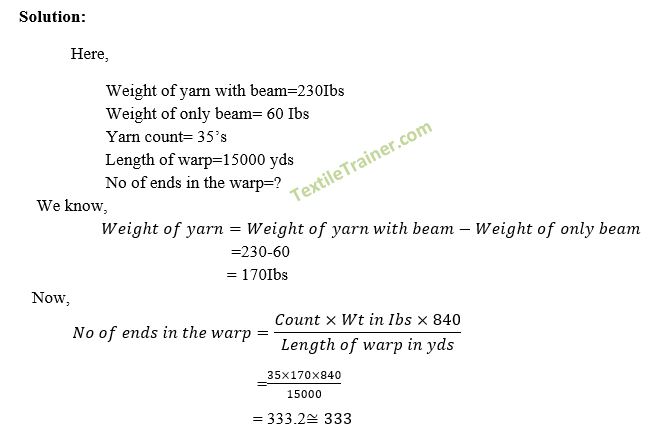

Exercise-1: Calculate the total no of ends on back beam which weights 230 Ibs. The weight of the empty beam as indicated from the marking its flanges is 60 Ibs. The count of the yarn is 35’s cotton and the length of warp on the beam is 15000 yds.

Exercise-2: Calculate the total no of ends on back beam which weights 303 Ibs. The weight of the empty beam as indicated from the marking its flanges is 63 Ibs. The count of the yarn is 25’s cotton and the length of warp on the beam is 12000 yds.(Self study, Answer-420)

Exercise-3: You are required to prepare a warp of 12000 yds from 1000 Ibs of 30’s twist. Calculate the no of ends yarn can have in the warp allowing 5% for waste and off on the bobbin. (self study, Answer-1995).

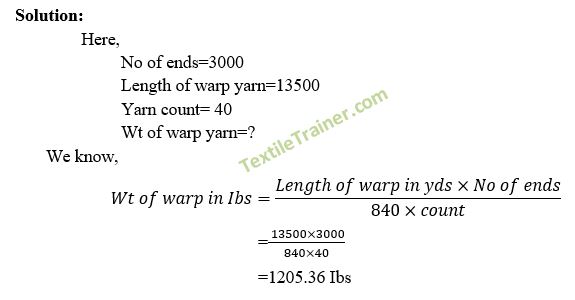

Exercise-4: calculate the wt of warp on a set of back beams which contains 3000 ends. The length of warp on each beam being 13500 yds and yarn count is 40’s.

Exercise-5: calculate the wt of warp on a set of back beams which contains 525 ends. The length of warp on each beam being 354816 yds and yarn count is 30’s.(self study, Answer-7392 Ibs)

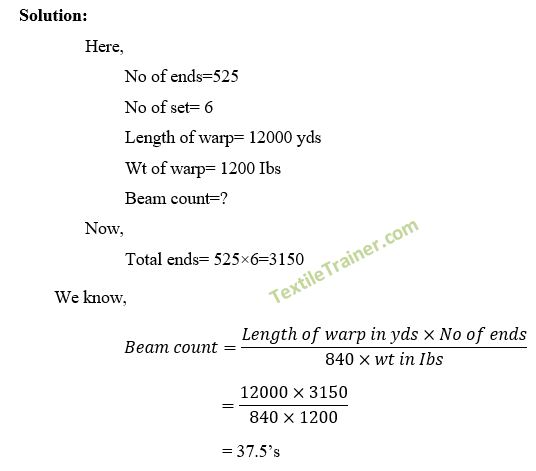

Exercise-6: Calculate the beam count of the yarn on a set of 6 slasher beams, each of which contains 525 ends of 12000 yds, at wt of warp on back beams is 12000 Ibs.

Exercise-7: A super speed warper machine warping 200 kg warp yarn. If length of warp yarn is 20000 m and total no of ends is 400, fine the beam count in tex( Self study, Answer- 25 tex)

Exercise-8: A warper’s beam produced on an improved modern high speed beam warping machine contains 39780 yds of warp with 420 ends. If net wt of the warp on the beam is 663 Ibs. Calculate beam count(Self study, Answer-30’s)

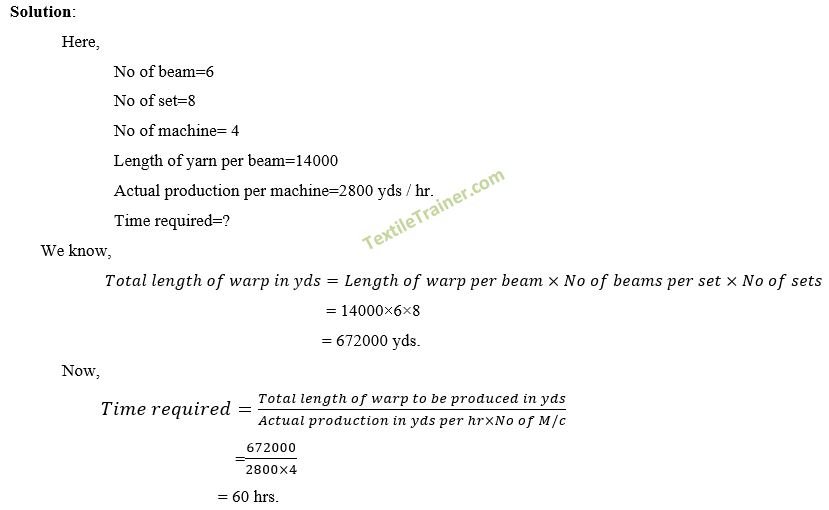

Exercise-9: 8 sets of 6 warper’s beams each is to be produced on 4 warping machines. The length of warp on each beam is required to be 14000 yds. If the actual production of each machine is 2800 yds per hr. how long will it take to complete the sets?

Exercise-10: Calculate the time required to prepare 6 sets of 5 warpers beams on 4 high speed warp machines with a warp length of 12000 yds per beam. The actual production per machine is 2600 yds per hour.( Self study, Answer- 34.62 hour)

Conclusion:

It is important to calculate warping in the textile industry. Warping refers to the process of preparing a set of parallel yarns that are used in weaving. An accurate and efficient warping calculation optimizes resource utilization, minimizes waste, and improves production. As a result of warping calculation, textile manufacturers can produce high-quality fabrics efficiently while minimizing waste and costs. Textile companies can improve their competitiveness and meet the market’s ever-changing demands by adopting technological advancements and employing precise calculation methods.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- Belal, P. D. (2016). Understanding Textiles for a Merchandiser. Dhaka: LB Graphics & Printing.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Rahman, M. M. (2008). Fabric Manufacturing Technology. Dhaka: Books Fair Publications.

- V. Gordeev, P. V. (1982). Cotton Weaving. Russia: Mir Publishers Moscow.