How to Measure Relative Humidity Using Hygrometer Easy Way

Experiment Name

Determination of relative humidity by using wet and dry bulb hygrometer. / Study on how to measure relative humidity using a hygrometer.

Introduction

Various atmospheric conditions closely impact fiber properties. Mainly, most of the fibers are hygroscopic in nature. Hence, they can absorb water vapor from a moist atmosphere as well as lose water in a dry atmosphere. The amount of moisture in the atmosphere is continuously changing under natural conditions. This results in a change in the amount of moisture in the fiber. The result of this change will be a change in the physical properties of the material such as tensile strength, elastic resistance, dimension, elastic recovery, rigidity, etc.

However, this experiment is about relative humidity (RH) and how relative humidity is measured using wet and dry bulb hygrometers. The relative humidity is the ratio of the actual vapour pressure to the saturated vapour pressure at the same temperature. It is expressed as a percentage. However, following the formula for measuring relative humidity.

- Relative humidity (RH)= {( Actual vapour pressure × 100)÷ saturated vapour pressure}

Objectives:

- To know about relative humidity.

- To know about wet and dry bulb hygrometer.

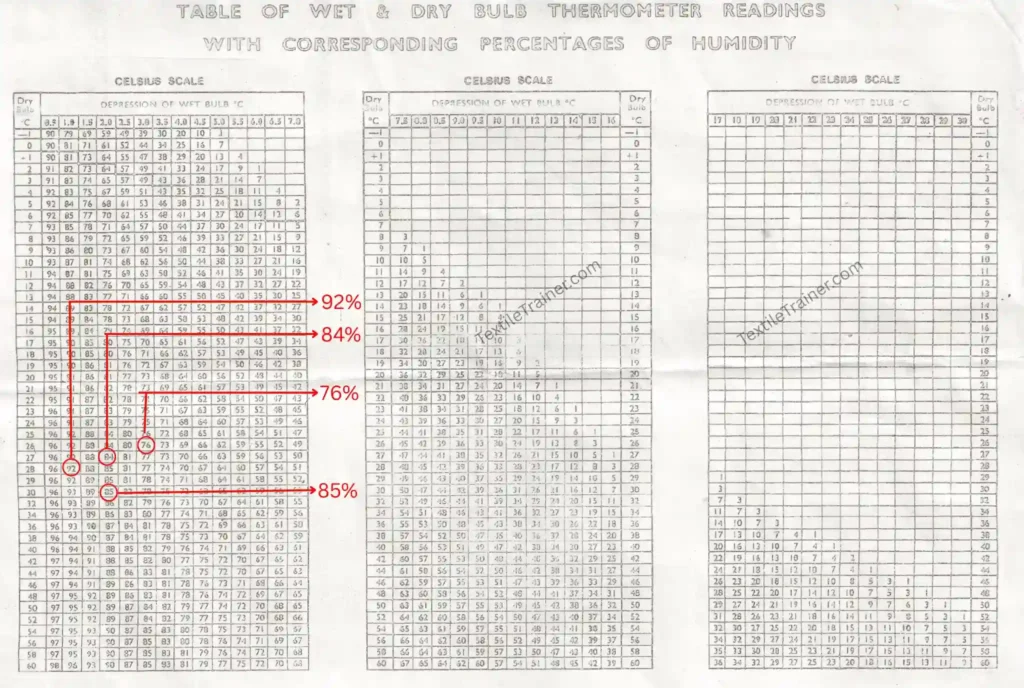

- Come to learn how relative humidity is measured using a standard chart.

- To learn the impact of relative humidity on fiber properties.

Apparatus:

- Wet and dry bulb hygrometer.

- Standard chart.

- Pencil

- Watch for time

Description

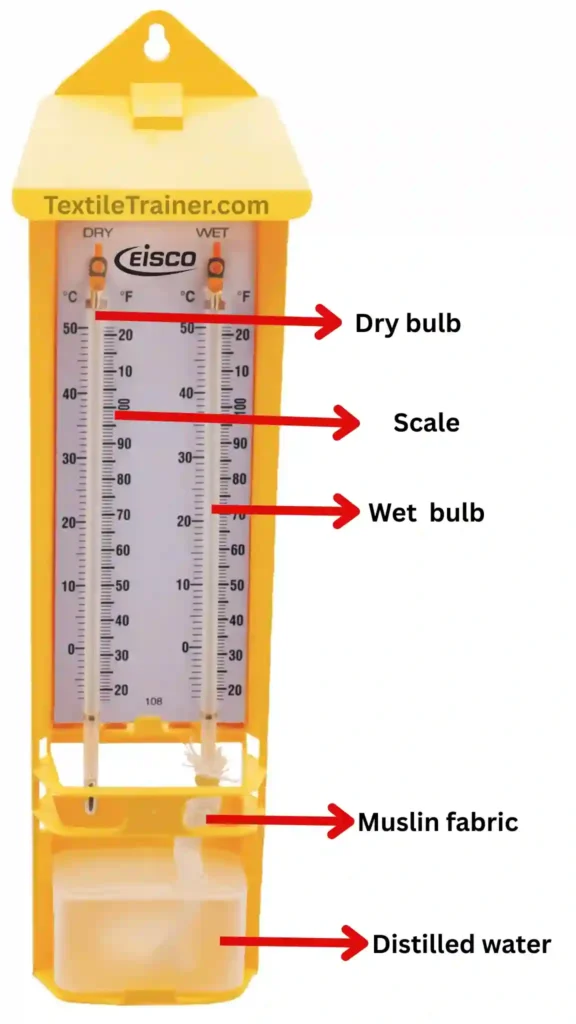

The wet and dry bulb hygrometer is shown in the figure. It consists of a frame on which two identical thermometers are mounted. One thermometer is called dry bulb and another thermometer is called a wet bulb. The wet bulb thermometer is covered by a muslin sleeve (fabric). Muslin fabric is dipped into a reservoir of distilled water. Hence, this bulb is called a wet bulb. The wet bulb thermometer always shows less temperature than the dry bulb thermometer. Besides, there are two scales that give Celsius and Fahrenheit temperature reading.

Working procedure Measure Relative Humidity

- Temperature doesn’t remain the same for the whole day. It is up and down according to the time. This experiment took five readings at five different times. (9.00 am, 10.00 am, 12.00 am, 2.00 pm, 4.00 pm)

- Then, the Dry bulb and wet bulb readings are noted down.

- Next, calculate the difference between the wet bulb and dry bulb temperature which is called the depression of the wet bulb.

- Subsequently, check the dry bulb column and depression reading column and find out the mutual point. A mutual point reading is the rating of relative humidity.

Measure Relative humidity

| Observation time | Dry bulb (T1) | Wet bulb (T2) | Depression (T1-T2) | Relative humidity (RH) | Average RH |

| 9.00 am | 260 C | 230 C | 30 C | 76% | 84.4% |

| 10.00 am | 270 C | 250 C | 20 C | 84% | |

| 12.00 am | 300 C | 280 C | 20 C | 85% | |

| 2.00 pm | 300 C | 280 C | 20 C | 85% | |

| 4.00 pm | 280 C | 270 C | 10 C | 92% |

Result:

Today’s relative humidity is 84.4%

Impact of RH

- Natural fiber especially cotton and wool fiber becomes more flexible and less brittle at high RH. Therefore, hand feel is increased.

- Besides, Elasticity of wool and silk fiber increases in high RH.

- But, Synthetic fiber does not show remarkable change at high RH.

- Static electricity of synthetic fibers increases at low Relative humidity.

- Additionally, Another problem with synthetic fiber is that synthetic fabric may feel sticky owing to poor moisture absorption.

Precaution

- Ensure the muslin fabric of the wet bulb is always dipped with distilled water.

- Besides, Keep the hygrometer far from windows, sunlight as well as a fan.

- Finally, keep stabilizing the instruments before taking the reading.

Conclusion

From this experiment learned how to measure relative humidity by using wet and dry bulb hygrometer. It is crucial to understand RH for climate control, research environment as well as industrial processing. However, thanked teacher to help which will be helpful in my career life.

References

- Booth, J. (2008). Principles of Textile Testing. New Delhi: BS Publishers & Distributors.

- Corbman, B. P. (1987). Textile Fiber to Fabric. Singapore: McGraw Hill Book Co.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- P. Angappan, R. G. (2009). Textile Testing. Tamil Nadu: S.S.M. Institute of Textile Technology.

You May Read

- Fiber Percentage Calculation for PC and CVC Fabrics: Easy 5 Step

- Single Yarn Strength Tester Working Principle with Easy Calculation

- Single Yarn Twist Testing Using The Straightened Fiber Method: Easy Explained

- Fiber Fineness Using the Gravimetric Method for Cotton

- Fiber Maturity on Direct Method: Caustic Soda Swelling Method