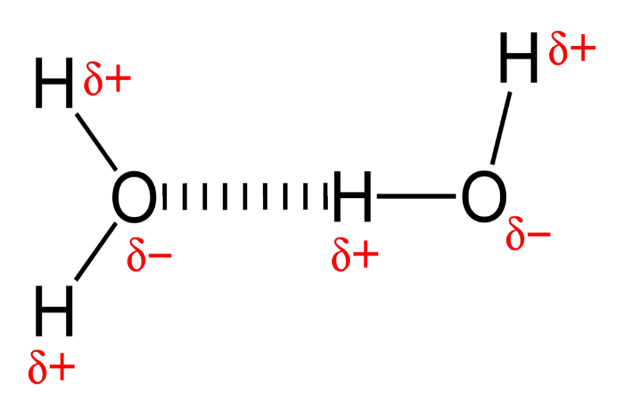

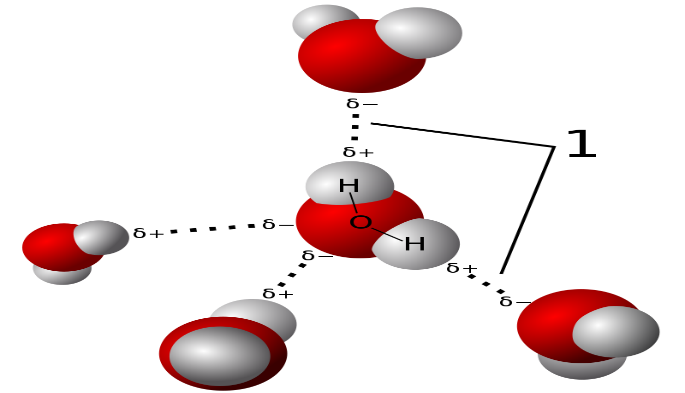

A substance composed of two moles of Hydrogen and one mole of Oxygen exists in solid, liquid, and gaseous states defined as water. The water is called another life which is transparent, odorless, colorless, tasteless chemical substances. Many H2O molecules come together and connect by Hydrogen bond (A bond generated by electronegative properties of atoms).water in wet process is describe in this article.

Figure: Hydrogen bond

Water is used everywhere in our day-to-day life such as cooking, Farming, washing and dyeing, drinking etc. Its boiling point of water is 100℃, melting point is 0℃, pH is 7, and density is 1000 kg/m3. Water has an H+ ion and an OH– ion, for having these two ions every solute can be easily soluble in water. that’s why we can say, water is called the best solvent. Now-a-day, we can’t think without water in textile industry. Every day there needs a much water intake, without water it is impossible to process any fabric.

Source of Water:

There are different source of water. But the main source of water is groundwater and others source of water are listed below. They are:

- Rain

- River

- Surface Water

- Ponds

- Deep Well (under 500 meter from the ground)

- Aquifer

- Stream

- Ocean water

- Ice caps and fields

- Lagoons

- Glaciers

- Subsoil water (under 50 feet from the ground)

Water Consumption in the Textile Industry:

Textile processing operations heavily rely on water. Most dyes, specialty chemicals, and finishing chemicals are applied to textile substrates from water baths. Aqueous systems are also used for fabric preparation, such as de-sizing, scouring, bleaching, and mercerizing. Some technical information of water consumption in the textile industry is given below:

- About 2.4 trillion of water is used per year for dyeing, it means 2.6% of water is used in textile mills worldwide.

- To grow one kilogram of raw cotton it takes ten thousand liters of water on average.

- A single T-shirt made of cotton needs water which is equivalent to water intake for a human being for three years

- More than eight thousand gallons of water is needed to cultivate the amount of cotton needed to manufacture a pair of jeans.

| Water Use in Textile Processing | |||

| Processing subcategory | Water use minimum, gal/ibs of production | Water use median, gal/ibs of production | Water use maximum, gal/ibs of production |

| Wool | 13.3 | 34.1 | 78.9 |

| Woven | 0.6 | 13.6 | 60.9 |

| Knit | 2.4 | 10.0 | 45.2 |

| Carpet | 1.0 | 5.6 | 19.5 |

| Stock/yarn | 0.4 | 12.0 | 66.9 |

| Non-woven | 0.3 | 4.8 | 9.9 |

| Felted fabrics | 4.0 | 25.5 | 111.8 |

Require Quality of Water in Textile Industry:

- Water for textile wet processing Should be soft and mild.

- Should be free of bicarbonate, sulfate, and chloride of Ca, Mg, Al, Fe, etc.

- Should be free of dissolved compounds and insoluble or floating matter.

- Should be free of ammonium compounds .

- Should be free of dissolved gasses, CO2, H2SO4, etc.

- At 4°C temperature, concentration should be high.

- Water should be pure, odorless, colorless, and tasteless liquid at an average temperature.

Why Water is Called Universal Solvent?

Most important question is why water is called universal solvent. Everybody should to know this answer. Water dissolves many solvents because it contains highly polar hydrogen bonds. Two sides of the molecule gain different charges, one side is positive H+, and the other side is negative OH-. Charge ends are heavily attracted to the charge ends of other compounds. That’s why all kinds of solutes dissolve in water, and it’s called a universal solvent.

Important of Water in Wet Processing:

- Fabric Pre-treatment: Before dyeing of process, fabric goes some subsequences process such as de-sizing, scouring and bleaching. These process is most important to get even dye shade. Because, these process is remove impurities, natural oils and sizing agents from the fabric. Carried out these process is impossible without water.

- Used as a Solvent for Dyes and Chemicals: Water is a universal solvent. It is used as a solvent for preparing dyes and chemicals for the textile industry. As a universal solvent, all the chemicals and dye easily mix up with water. During dyeing a fabric, water is mainly used to disperse the paint, and water ensures that a fabric has staining properly in the eleventh hour.

- As a Medium for Transferring Dyes: Water is an essential part of wet processing in textile industry. Water acts as a transfer medium in wet processing. it is a medium for dyes, chemicals, and additives to be transported onto the fabric so to penetrate the fibers and achieve the desired effects.

- Chemical Reaction: In many wet processing steps, chemical reactions take place, for example, the fixing of dyes to fibers or the application of special finishes. Water acts as a medium for these chemical reactions. Water helps to chemicals crosslink during the finishing process. By helping of chemical reaction, water can improve fabric properties, such as softness, wrinkle resistance, and water resistance.

- As a Washing and Rinsing medium: A suitable solvent is water. When treated with detergent, which is soluble in water and forms a lather in water, it combines with filth and other particles. So considering its solubility, it serves a purpose in cleaning. With water, this process can be done correctly.

- Dispersion and Dissolving: We know, water has unique properties of solvency and dispersion. Dyes, chemicals and additives in dyeing bath must be dissolved or dispersed in water in order to create stable dyeing solution. Water helps to evenly distribute all these substances and helps to interact effectively with the fibers.

- Temperature Control: Water plays an important role in wet processing. In order to achieve optimal results special dye shade, required specific temperatures. Water acts as a heat carrier, which regulates the temperature evenly in dyeing bath.

What is the Alternative of Water in Wet Processing?

Nothing can be used as an alternative to water because water is a cheaper and more available solvent than all. Only recycled water can replace water. The main source of water is groundwater, nowadays the layer of the water falling in the future we can’t use much water we need to replace it with recycled water. We need to find a way to recycle the wastewater in industries. If we don’t take these kinds of steps fast, one day, our central export sector will vanish, and people will be jobless. It is an economical process, but we need to do it efficiently so that our country can face the upcoming challenge because Necessity is the mother of invention. So we should search alternative of water. Many researcher are searching alternative of water in wet processing. Some methods are invented which is still now under research.