Introduction:

During the preparation of raw materials for further processing, the operating zone within the blow room plays a crucial role. The fiber material is carefully handled in this zone to ensure its cleanliness, uniformity, and suitability for subsequent steps. The zone comprises a range of machinery and equipment that work in tandem to achieve these objectives. You will find bale openers, pre-cleaners, and fine cleaners in this zone, each with a specific purpose. Bale openers meticulously separate fibers from bales, ensuring smooth transition into production lines. Pre-cleaners are used to enhance fiber quality by removing impurities such as dust, dirt, and other unwanted particles. As a result, the fiber material is cleaned and refined further by fine cleaners, which eliminate remaining impurities.

Operating Zone in Blow Room:

There are various operation zones in the blow room and these can be classified as following:

According to sequence of operation:

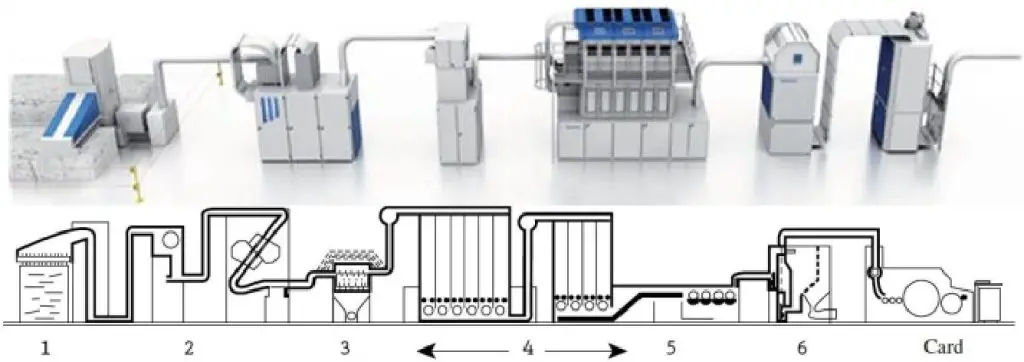

Today the less number of beating points are used and blow room consist of following zone. According to sequence of operation blow room operative zone can be divided as follows:

- Opening zone

- Protective cleaning zone

- Coarse cleaning and opening zone

- Blending zone

- Intensive fine cleaning zone

- Foreign part separator

- Dust cleaning zone

- Card feed zone.

According to Type of Operation:

The operating zone in the blow room basis on type of operation carried out can be grouped as follows:

- Opening zone-without beater: spinning mill receive the fiber in the form of bale, in which fiber be with very high compression and to process this material to the next process it should be open out. In this zone, only opening operation is performed Automatic Bale Opener.

- Opening and cleaning zone-with beater: the incoming bales contain natural impurities along with foreign material and therefore, the fiber tuft should be cleaned. Opening and cleaning operation both are performed simultaneously in this zone by the combination of action of beater and grid bars, i.e. coarse and fine cleaning and opening zone.

- Cleaning zone-without beater: cleaning action is performed only in this zone without any beater. Though they are optional selection zone but they are essential part in modern blow room line for quality product and trouble free operation. There are three types of point installations in this zone:

- Protective cleaning zone-sensitive (Fire and metal) parts separator: in this zone metallic part, big size trash etc is separated from the fiber tufts using imbalance centrifugal and aerodynamic force. If these material flows with tufts to the beating points then damage of beater wire and fire-in occurrence takes place.

- Dust cleaning zone-fine part separator: the impurities are removed in the opening and cleaning zone sequentially. But the dust which is trapped within the ffifber tufts cannot be removed. The impact of dust is significantly justified in the report of winding cuts. Ater opening to very small tufts, employing suction pressure the dust particle are removed through the perforated drum. The process by which dust particles are removed is called de-dusting. De-dusting should be after intensive opening and cleaning.

- Color material cleaning zone-foreign part separator: the color material except raw material is known as the foreign material. The color materials do not produce any mass variation but color variation in the product and causes financial loss to the end product producer. This type of foreign impurities cannot be removed by the traditional cleaning device but the optical sensors to be employed to detect such type of faults and sudden blow of compressed air remove this impurities-vision shield, magic eye.

4. Mixing zone: we know natural fiber belongs to variation in fiber properties. To produces the yarn with regularity, the variability in fiber properties to be minimized by mixing. Therefore, for homogenization in fiber properties mixing zone is used.

5. Card feed zone: card frame should receive an even and compact feed material. If this condition is not fulfilled then carding performance both in terms of quality and production will be deteriorated. In this zone output of blow room is prepared suitable for card frame.

Conclusion:

During textile manufacturing, the operating zone of the blow room plays a vital role in ensuring that raw fibers are clean, uniform, and suitable for subsequent processing stages. It plays a crucial role in preparing raw fibers for further processing. Impurities are effectively removed from fibers through the use of specialized machinery and equipment, leading to cleaner and more refined fibers. In addition, the operating zone regulates and controls the flow of fibers, ensuring smooth production.

References:

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Corbman, D. P. (1983). Textiles Fiber to Fabric. NewYork: Mary McGarry.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.

- Rieter Manual for Spinning, Volume-II

Very good blog article.Really looking forward to read more. Cool.

thanks for comments.

Really appreciate you sharing this article.Thanks Again. Will read on…

please support us.

I really liked your blog.Thanks Again. Really Cool.

please support us.

Really appreciate you sharing this post.Really thank you! Awesome.

thanks too…..

Thank you for your blog.Thanks Again.

keep visit our site… .

This is one awesome post. Cool.

please share our article…

Hey, thanks for the article post. Awesome.

please support us….

I appreciate you sharing this post.Really thank you! Will read on…

thanks too. please support us.

Thanks for sharing, this is a fantastic post.Really looking forward to read more. Cool.

thank too…..please support us…

I used to be recommended this blog via my cousin. I am no longer sure whether or not this post is written via him as nobody else know such distinct about my problem. You are amazing! Thank you!

thanks too. please support us.

Thanks for the blog post.Really looking forward to read more. Cool.

Definitely, what a magnificent blog and instructive posts, I surely will bookmark your blog.Have an awsome day!

Thanks a lot.stay with us.

Im thankful for the post.Really thank you! Great.

Thanks again for the article post.Really thank you! Keep writing.

Great blog article.Really looking forward to read more. Really Great.

keep visiting our site…..

Thanks a lot for the article. Awesome.

Thanks so much for the blog.

thanks too

Thanks so much for the article.Really looking forward to read more. Great.

keep visit our site…

Im obliged for the blog.Much thanks again. Keep writing.

Thanks for sharing, this is a fantastic post.Thanks Again. Awesome.

Hello, yes this article is actually pleasant and I have learned lot of things from it about blogging. thanks.

Itís hard to come by well-informed people in this particular subject, but you sound like you know what youíre talking about! Thanks

I am so grateful for your post.Thanks Again. Much obliged.

Very neat blog post.Thanks Again. Will read on…

Thanks again for the post.Much thanks again.

Some really interesting information, well written and loosely user friendly.

Im grateful for the post.Really thank you! Want more.

I am so grateful for your blog article.Thanks Again. Will read on…

Hey, thanks for the post.Much thanks again. Fantastic.

Im obliged for the article. Will read on…

Im grateful for the blog post.Really thank you! Cool.

Really appreciate you sharing this blog article.Much thanks again. Keep writing.

Appreciate you sharing, great blog post.Really looking forward to read more. Really Great.

I really enjoy the article post. Great.

Very good article.Much thanks again. Cool.

A big thank you for your post.Much thanks again. Really Cool.

A big thank you for your article. Fantastic.

Looking forward to reading more. Great blog.Really thank you! Much obliged.

Im grateful for the post.Thanks Again. Really Great.

I am so grateful for your blog post.Really thank you! Will read on…

Looking forward to reading more. Great blog article.Really thank you! Really Great.

Really informative blog article.Thanks Again. Awesome.

Great, thanks for sharing this blog. Fantastic.

A round of applause for your article.Much thanks again. Want more.

Major thanks for the article.Really looking forward to read more. Want more.

Really enjoyed this blog. Really Great.

Major thankies for the blog.Much thanks again. Fantastic.

Very good blog post. Really Great.

Say, you got a nice blog article.Thanks Again. Really Cool.

wow, awesome post. Keep writing.

Enjoyed every bit of your blog post.Really looking forward to read more. Really Cool.

Enjoyed every bit of your blog article.Much thanks again. Great.

Thankfulness to my father who stated to me regarding this blog, this blog is in fact amazing.

Thank you for your post.Really looking forward to read more. Much obliged.

Thank you

Really enjoyed this post.Really thank you! Really Great.

Very neat blog article.Much thanks again. Cool.

Very good blog article.Really looking forward to read more. Awesome.

A big thank you for your article post.Really thank you! Really Cool.

I truly appreciate this blog.Really thank you! Fantastic.

Thanks so much for the article. Really Great.

Appreciate you sharing, great blog article.Thanks Again. Fantastic.

I appreciate you sharing this post. Great.

A big thank you for your blog post.Really thank you! Really Great.

Very informative article post.Really looking forward to read more. Much obliged.

Looking forward to reading more. Great blog.Really looking forward to read more. Fantastic.

You need to know when the ball is going towards you.

Great, thanks for sharing this blog article.Much thanks again. Really Cool.

Really appreciate you sharing this blog article.Much thanks again. Will read on…

Say, you got a nice blog article.Really looking forward to read more.

wow, awesome post.Much thanks again. Great.

Very neat article post.Really thank you! Cool.

wow, awesome blog post. Great.

I think this is a real great article post.Really looking forward to read more.

I truly appreciate this blog article.Thanks Again. Great.

Great, thanks for sharing this post.Really thank you! Fantastic.

This is one awesome blog post.

wow, awesome article post.Really thank you! Awesome.

Awesome article.Thanks Again. Cool.

Appreciate you sharing, great blog post.Really looking forward to read more. Keep writing.

Im grateful for the article. Want more.

Hey, thanks for the article.Much thanks again. Keep writing.

I really enjoy the blog post.

Looking forward to reading more. Great article.Much thanks again. Great.

I really liked your article post.Really looking forward to read more. Really Cool.

Hey, thanks for the blog.Really thank you! Much obliged.

This is one awesome article.Really looking forward to read more. Want more.

I really enjoy the blog post.Much thanks again. Really Great.

Thanks for the article.Thanks Again.

Thanks a lot for the article.Thanks Again. Great.

I loved your blog post.Really thank you! Really Cool.

I really like and appreciate your article post.Much thanks again. Will read on…

Really appreciate you sharing this article post.Really looking forward to read more. Keep writing.

wow, awesome post.Thanks Again.

I appreciate you sharing this blog post.Thanks Again. Much obliged.

I truly appreciate this blog article.Much thanks again. Really Great.

I really liked your blog article.Really looking forward to read more. Really Great.

Very neat post.Really thank you! Cool.

Hey, thanks for the article.Really thank you! Really Great.

Awesome article.Really thank you! Cool.

Really informative blog.Thanks Again. Fantastic.

Im thankful for the article post. Want more.

Thanks for the blog post. Want more.

Great post.Really looking forward to read more.

A round of applause for your article. Awesome.

That is a really good tip especially to those new to the blogosphere. Brief but very precise informationÖ Thanks for sharing this one. A must read post!

Welcome

I really liked your article post.Thanks Again. Want more.

Very neat blog article.Really thank you! Really Great.

wow, awesome article. Really Cool.

Thanks

Very good article post.Thanks Again. Keep writing.

Very neat blog article.Really looking forward to read more. Great.

Thank you ever so for you blog.Really looking forward to read more. Fantastic.

Hey, thanks for the blog.Thanks Again. Really Great.

Hey, thanks for the post. Awesome.

I am so grateful for your article post.Really looking forward to read more. Keep writing.

Thanks for sharing, this is a fantastic article. Want more.

A big thank you for your article.Really thank you! Keep writing.

Really appreciate you sharing this article.Much thanks again. Awesome.

Looking forward to reading more. Great blog post.Really thank you! Want more.

I truly appreciate this post.Much thanks again. Fantastic.

Looking forward to reading more. Great article.Thanks Again. Want more.

I think this is a real great article.Really thank you! Really Cool.

Looking forward to reading more. Great post.Much thanks again. Fantastic.

Say, you got a nice post.Really thank you! Will read on…

I really enjoy the blog article.Much thanks again. Want more.

Fantastic article post.Really thank you! Keep writing.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis. Kerassentials is a convenient, easy-to-use formula. https://kerassentialsbuynow.us/

I really liked your blog.Really thank you! Want more.

A big thank you for your blog article. Keep writing.

Thank you for your post.Thanks Again. Want more.

Thanks a lot for the article post. Want more.

I think this is a real great blog post. Fantastic.

Major thankies for the post. Want more.

I value the blog post.Really thank you! Really Great.