Introduction:

The blow room is a critical stage in the textile manufacturing process, where raw cotton fibers undergo essential preparatory steps before being further processed. In a blow room, the opening process involves the separation, cleaning, and blending of fibers to ensure uniformity and consistency. In order to maximize efficiency and achieve desired results, it is crucial to understand the types of opening, the factors influencing the opening process, and the degree of opening.

This article aims to provide a simplified overview of the types of opening, factors influencing the opening process, and the degree of opening in the blow room. We will explore the fundamental principles behind these aspects and their importance in the process of fiber processing by breaking down complex concepts into easy-to-understand terms. Initially, we will examine the various types of opening mechanisms used in the blow room, including the principles that underpin individual types, such as beater openers and blade openers. Understanding their specific functionalities will allow readers to gain a better understanding of the advantages and limitations of each opening method and how they contribute to blow room efficiency as a whole. The next step will be to discuss the factors influencing the opening process. Cotton fiber characteristics, such as staple length, fineness, and trash content, as well as equipment parameters, such as beater speed, grid bar spacing, or opening elements, all contribute to these factors. Understanding these factors will enable readers to optimize the blow room process based on their specific needs. Finally, we will discuss the degree of opening and its importance in achieving desired fiber characteristics. The degree of opening refers to the degree to which fibers are separated and blended during the opening process. During this course, we will examine how the degree of opening impacts the subsequent processing stages, including carding and combing, as well as the end product’s quality and uniformity. Readers will be able to make informed decisions to achieve the desired fiber properties for their textile products once they understand the concept of degree of opening.

understanding the types of openings, factors influencing the process, and the degree of opening in the blow room is crucial for optimizing the efficiency and quality of textile manufacturing. By providing a simplified approach to these complex concepts, this article aims to empower readers with the knowledge needed to make informed decisions and achieve desired results in the blow room.

Types of Opening:

Depending on the size of the fiber package that is produced, the opening is classified into two groups.

- Opening to flock: In this system, fiber packages are opened in the blow room and the flock or tuft packages are placed inside.

- Opening to individual fiber: This system opens the fiber package in order to expose individual fibers in cards, OEs, and Combers

The opening can also be classified based on the technological viewpoint, i.e. changes in the dimension of the fiber packages occur after the process has been carried out as follows:

- Opening out: The term “this type of opening” refers to situations in which the volume of flock increases while the number of fibers remains the same, i.e. the density decreases. As a result of measured values, it has been found that a typical open out value for a bale of cotton at the beginning of an opening and cleaning line is approximately 51 cm3/g, while the OV at the end of the line can be more than 140 cm3/g.

- Breaking apart: A flocking opening of this type is one where the volume of the flock, the number of fibers, but not the density of the flock, change over time.

Degree of Opening:

In order to assess the opening action value of a beater, we use a measure of the degree of opening. The degree of opening is the intensity of opening that is measured in order to estimate the opening action value of the beater. It is important to remember that the degree to which cotton fibers are opened affects the degree to which they blend. A blow room is a process where individual fibers are separated thoroughly and then reassembled uniformly in order to create a consistent blend of fibers with desired properties, such as staple length, fineness, and color, as well as a consistent blend of fibers. This blending process is crucial for achieving uniformity in the final textile product and maintaining the desired characteristics throughout the manufacturing process.

Factors for Degree of Opening:

There are a number of factors that influence the degree of opening, including:

Raw Materials:

- Thickness of feed: The degree of opening will be reduced if the thickness increases.

- Density of the feed: A reduction in density will result in a reduction in the degree of opening.

- Fiber coherence: The degree of opening will be reduced if the degree of cohesiveness in the fiber assembly is increased.

- Fiber alignment: There will be a greater degree of opening if the degree of alignment is higher.

- Size of the flock: It is important to keep in mind that the degree of opening will vary based on the size of the flock. Larger flock sizes result in more surface areas of action which means there will be more points per flock and greater inter-fiber coherence.

Machine or Device:

- Type of feed: In contrast, clamped feeds indicate a lower degree of opening, while loose feeds indicate a higher degree of opening.

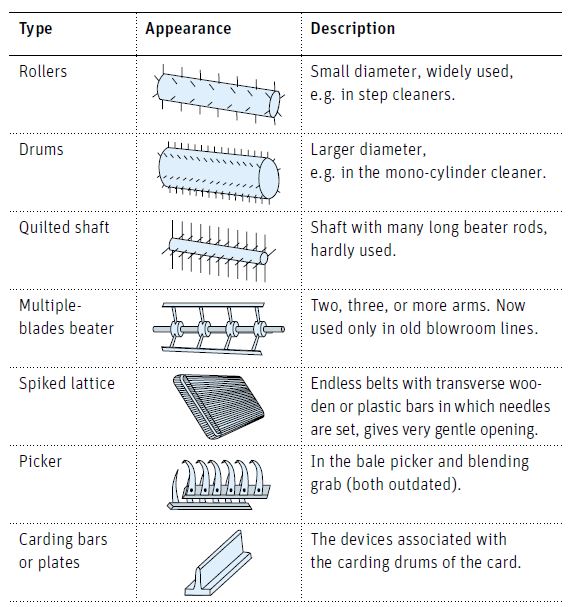

- Type of opening device: There are several different types of opening devices. Depending on which kind of opening device you are using, the degree of opening will vary.

Profile of Opening Device:

There are a number of factors that affect the profile of the opening device, for example, clothing type, point density, point angle, point height, as well as the arrangement of clothing.

- Type of clothing: The degree of opening for clothing that is flexible will be less, while for clothing that is metallic, the degree of opening will be greater.

- Point density of clothing: When the point density is higher, then the degree of opening will be higher, and when the point density is lower, then the degree of opening will be lower.

- Point angle: Depending on the arrangement of clothing, it may fall into the category of a regular or irregular pattern. It is more likely that the irregular pattern will prevail.

- Arrangement of clothing on surface: The arrangement of cloth can be divided into two types: regular and irregular. The irregular pattern has a higher degree of opening than the regular pattern. Clothes arrangement may also be arranged as a carding arrangement or a doffing arrangement. Generally, carding arrangements have a greater degree of opening than doffing arrangements.

Speed:

- Speed of the opening device: In general, the higher the speed of the opener, the greater the degree of opening.

- Production speed of the material: A faster rate of production translates into a lower degree of opening due to the higher speed of production.

Conclusion:

In order to maintain a productive and efficient textile production process, it is very important to understand the various types of openings, factors, and degrees of openings in the blow room. We have explored the fundamentals of blow room operations through an overview of these concepts in an easy-to-understand manner by providing an overview of these concepts. Please leave a comment if you have any questions or comments about this article.

References

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L. B Graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Corbman, D. P. (1983). Textiles Fiber to Fabric. NewYork: Mary McGarry.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.

1 thought on “An Overview of Types of Opening, Degree of Opening and Factor in Blow Room is Described Easy Way”