Introduction:

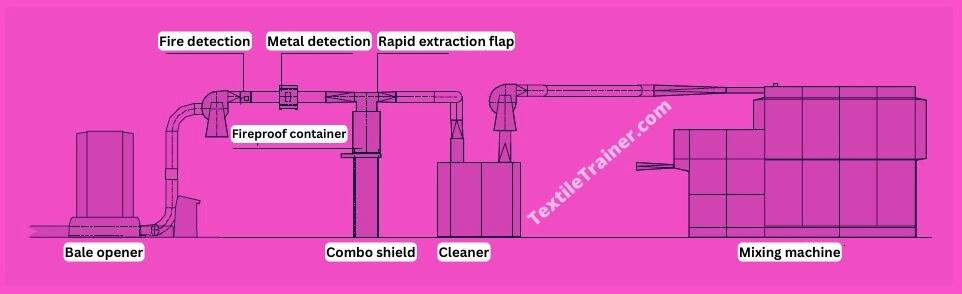

In this article, the Rieter Combo Shield will be introduced to you. Rieter combo shield used in rieter blow room line. This machine is Designed to enhance safety in textile manufacturing. This machine efficiently detects and removes metals, sparks, and embers from fiber tufts through its metal and spark detection systems. A Combo Shield is a versatile safety solution that can be tailored to meet the needs of any company. In situations where additional precautions are required, the system can be equipped with the metal detector Metal Shield and/or the spark detector Fire Shield. This ensures comprehensive protection throughout the production line. The Rieter Combo Shield provides peace of mind by addressing potential fire hazards and safeguarding machinery. With this innovative solution, blow room will be safer and more efficient than ever before.

Function of Rieter Combo Shield:

- spark detector: Combination shields comprise spark detectors. Spark detectors turn on a rapidly operating flap as soon as they detect sparks or burning material. Material passes into a receiving container, which is usually outside the room. In parallel, an alarm is generated, and the blow room line and filter installation are turned off.

- metal detection: A Rieter combo shield also includes a metal detector. With the use of metal detectors, metallic particles can be removed from the transport duct along with cotton tufts. A metal particle is a significant threat to machinery in the future, as it can cause damage or cause fire hazards. To detect and remove material parts from cotton tufts, metal detectors are used.

- Eliminating device: Metal particle eliminating devices remove the extracted metal particles from a system. These devices ensure that the particles are safely removed, preventing damage to subsequent equipment.

Overall, the Rieter Combo Shield is a comprehensive protective installation that aims to enhance safety in the blow room of textile manufacturing. It minimizes the risk of fire and machinery damage by combining spark detection, metal extraction, and elimination.

Working Principle of Rieter Combo Shield:

After the cotton bale is opened by an automatic bale opener, cotton tufts are fed into the Rieter Combo Shield via a transport duct. First, cotton fibers pass through fire detection or spark detection. As soon as a fire detection system detects sparks or burning materials, the rapidly operated flap pivots. In addition, an alarm is given, as well as the blow room line and filter installation are turned off. The material passes into a receiving container preferably outside the room. During the next step, cotton passes through a metal detector. Metal detector detects metal parts. Metal particles pose a risk to the machinery in the future, as they can cause damage or ignite fires. Metal detector separates metal parts from the cotton tufts. If such a piece of material is detected, the rapidly operating flap pivots and the material is ejected into a container. After an adjustable period, the flap returns to its original position.

Conclusion:

The Rieter Combo Shield is a powerful, reliable system for textile manufacturing that prioritizes safety. A metal and spark detection system enables it to identify and eliminate potential hazards like metal parts, sparks, and embers effectively. By combining advanced technology with optional additional components, it offers comprehensive protection. Utilize the Rieter Combo Shield to enhance safety, optimize efficiency, and gain a new level of confidence in your blow room operations.

References:

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Corbman, D. P. (1983). Textiles Fiber to Fabric. NewYork: Mary McGarry.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.

- Rieter manual for spinning, Volume-II

Awesome post.Really looking forward to read more.