Introduction:

Silk is a natural protein fiber. It is similar to wool. Bothe these fiber is composed of amino acids arranged in a polypetide chain, although it does not have cross links. Silk is the only natural filament fiber made by larvae of moths. We will describe the silk manufacturing process in this article. Silk is a solid fiber with an irregular diameter along its shaft. It has triangular filaments with a smooth surface.

Silk Manufacturing Process:

There are six steps in the silk manufacturing process:

- Sericulture.

- Sorting of cocoons.

- Softening the sericin.

- Reeling.

- Bailing.

- Throwing.

1. Sericulture:

Sericulture is the process of breeding, nurturing and caring for silkworms. Commercial silk is made from the filaments produced by the mulberry silk moth, Bombyx mori,and a few other species belonging to the same genus. Insects such as moth caterpillars and other insects are the main sources of silk production. The silk production process is highly complex and labor intensive. Here are the basic details about the manufacturing of silk. Sericulture is a four-step process:

- a) Eggs

- b) Hatching the Eggs

- c) Moulting

- d) Spinning the Cocoon

a) Eggs:

Most females moth lay eggs between 150 and 300 over the course of two to three days. Some moths lay as many as 1,000 eggs. If the eggs do not change color, they are probably infertile.

b) Hatching the Eggs:

The first stage of silk production is the laying of silkworm eggs. This process is done in a controlled environment such as an aluminum box, that are then examined to ensure they are free from disease. A silkworm moth’s tiny eggs are incubated (about 1 day) for about a quarter of an inch until they hatch into larvae (caterpillars).

c) Moulting:

A silkworm larva consumes mulberry leaves continuously, molts four times, and produces silk that is of the highest quality. During the course of about six weeks, the silkworm eats virtually continuously, and they never stop eating. The silkworm stops eating, changes color, and weighs about 10,000 times more than when it hatches. Once it reaches its maximum size of about three inches, it stops eating, changes color, and is ready to spin silk cocoons.

d) Spinning the cocoon:

The silk fluid is extruded from a spinneret located under the lower lip of a tow. The spinneret is fed by the tow glads, and the emerging filaments are coated with silk gum, called sericin. The diameter of the spinneret determines the thickness of the silk yarn, which is produced as a long continuous yarn. In the presence of air, the secretions harden into twin filaments containing protein material called fibroin. A second pair of glads secretes sericin, a gummy glue that binds the filaments together. The silkworm continuously rotates its body in movement some 3,00,000 times over the next four days, building a cocoon of silk filament around the body of the insect. In a cocoon, the pupa changes into a moth after 3 days. Within 3 days, a twin filament of about 2000 m is created. Spinning usually takes about two or three days. It takes approximately 14 days for a pupa to become a moth. Moths cut the cocoon to fly out and damage the silk, so pupas must be killed by steam or hot water immediately after making their cocoons.

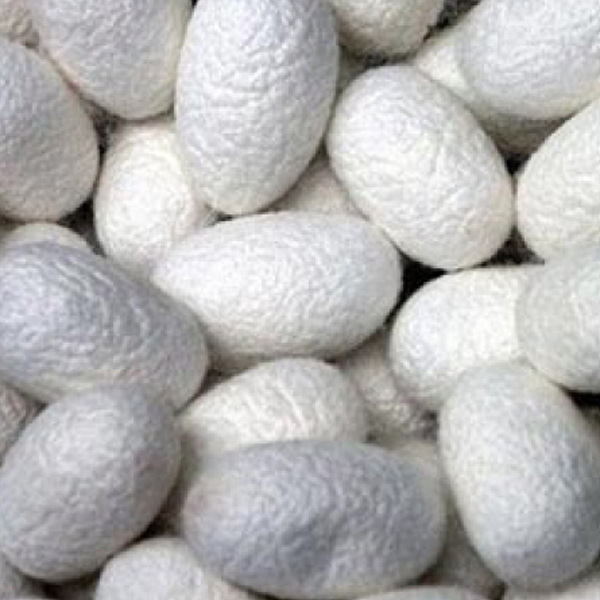

2. Sorting cocoons:

The final quality of the silk is determined by the color, size, shape, and texture of the cocoons. Silk cocoons can range in color from white to yellow to gray. Sericin is extremely weather resistant, as demonstrated by the ability of silk cocoons to withstand prolonged exposure to the elements.

3. Softening the sericin:

A silk filament consists of two strands of fibroin that are held together by sericin, a gummy substance. Sericin must be softened in order to allow the filament to be unwound as one continuous thread, so after the cocoons have been sorted they undergo a series of hot and cold immersions.

4. Reeling the filament:

The process of reeling involves unwinding silk filaments from cocoons and combining them into raw silk threads. In order to make raw silk of the desired diameter, three to ten strands of cocoon filament are reeled at a time, which is known as reeled silk, because the filaments are too fine for commercial use. At this stage, hot air, steam, or boiling water are used to treat the cocoon. In order to unbind the silk from the cocoon, the sericin has to be softened and the filaments carefully unrolled from 4 – 8 cocoons at once, sometimes twisting the thread, to form one strand of silk. A reeled filament is capable of being used for 300 to 1200 meters. Raw silk contains sericin, which protects the silk fibers during processing. When it is cleaned out (in soap and boiling water), the fabric becomes soft, lustrous, and lighter by 30%. To produce one pound of raw silk are required about 2500 silkworms. Each cocoon contains a small amount of usable silk. Reeled silk is a bundle of continuous filaments about 1000 metres long, coming from the middle part of the cocoon. They are still cemented together by gum. Later, several of these bundles will be twisted together to form silk.

5. Bailing:

In this form, raw silk is shipped to silk mills all around the world in bundles, called books, weighing 2 to 4.5 kg each. These books are then packaged into bales weighing about 60 kg each.

6. Throwing of silk:

To create silk yarn, raw silk is twisted into a strong stand suitable for weaving or knitting. The process of winding and doubling of silk is known as “throwing”. This prevents the thread from splitting.

It is quite easy to manufacture silk yarn by following these steps. I tried to describe these as simply as possible. If you have any questions, please leave a comment on the comments section.

Reference:

- Cook, J. G. (2005). Handbook of Textile Fibers. Delhi: WoodHead Publishing Limited.

- Corbman, B. P. (1987). Textile Fiber to Fabric. Singapore: McGraw Hill Book Co.

- Dr. Hosne Ara Begum, P. D. (n.d.). Natural fibers. Dhaka: Hafiz book center.

- Kadolph, S. J. (2006). Textiles. New Delhi: Pearson Education.

4 thoughts on “6 Easy Step of Silk Manufacturing Process”