Name of the Experiment:

Study on passage of yarn through pirn winding machine

Introduction:

In weaving, yarn is the basic building block, so after yarn manufacture, the next step would be weaving the yarn into fabric. The condition of the yarn produced on the spinning machine is not always good enough to be used directly for fabric production in practice. For fabric formation to be efficient, both weft yarns and warp yarns need to be further processed based on package size, yarn surface characteristics, and other factors. During weaving, warp and weft yarns are subjected to different conditions and requirements. Therefore, preparation of warp and weft yarns is different. Because warp yarns are subject to a higher level of stress, they require additional preparation. Weft yarns, however, do not undergo the same level of stress as warp yarns, so they are much easier to prepare for weaving. The main preparation process for weaving is winding. The purpose of this experiment is to learn about the passage of yarn through a pirn winding machine.

Objectives:

- To know about winding process.

- To know passage of yarn through pirn winding machine.

- Come to learn different winding zone of pirn winding machine.

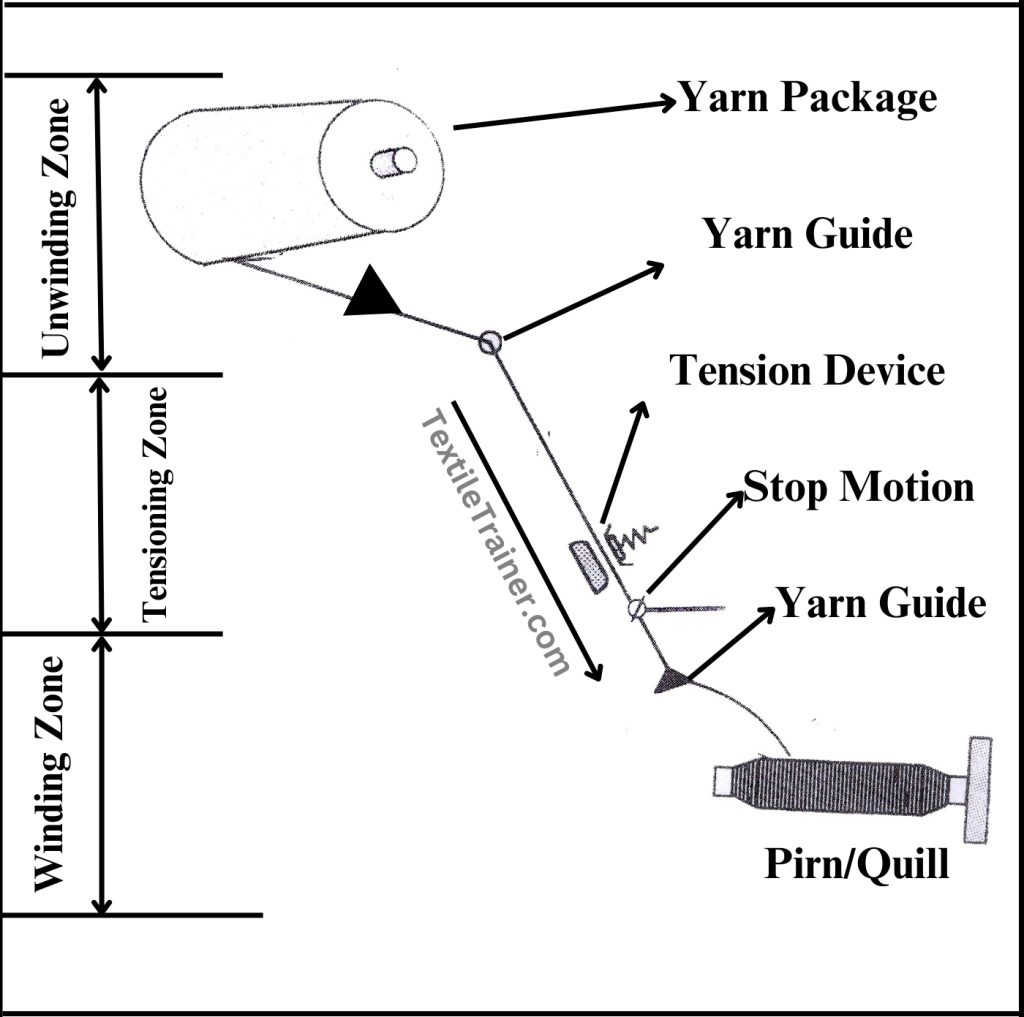

In the pirn winding machine, there are three major zones. They are:

- Unwinding zone.

- Tensioning zone.

- Winding zone.

Schematic Diagram of Pirn Winding Machine

Winding Principle of Pirn Winding Machine:

- At the unwinding zone, a large package of yarn is feed in pirn winding machine. During the production process of pirn bobbins, large packages are held in an optimal position in the creel. In the yarn guide, the yarn is aligned and positioned correctly so that it winds onto the quill accurately and smoothly.

- Now the yarn is passing through the tension device. As the yarn is wound on a quill or other packaging, it is kept under constant tension. Maintaining proper tension is crucial for achieving uniform winding and preventing yarn breakage, snarls, or uneven package formation.

- The yarn is then passed through a stop motion. The stop motion is used to stop winding if the yarn breaks or runs out. Stop motions may vary from machine to machine. In the presence of yarn, a counter-weighted or spring-loaded sensing device holds inactive, causing the sensing device to activate. As the yarn breaks or runs out, the sensing device becomes active, detecting yarn without mechanical contact.

- As soon as the yarn passes through the guide, it goes to the traversing mechanism.

- A quill winding machine is equipped with a traverse mechanism that moves the quill horizontally while winding yarns. By creating a uniform distribution of yarn across the quill, the traverse mechanism prevents excessive yarn build-up in one area.

- The machine is ready to use when quill holders or spindles are set up.

- After the desired amount of yarn has been wound onto the quill, or when the quill has reached its maximum capacity, the machine automatically stops, the yarn is cut, and the quill is removed.

- Upon removing the full quill, an empty quill is placed in the quill holder, and the process is repeated.

Conclusion:

There are many benefits to using a pirn yarn winding machine in weaving to improve yarn winding efficiency. Nevertheless, we learned a lot from this experiment about pirn winding machines and their schematic diagrams, as well as their working principle. In the future, this will be useful for our industrial life.

Reference:

- Belal, P. D. (2016). Understanding Textiles for a Merchandiser. Dhaka: L.B Graphics and Pringing.

- Gandhi, K. (2012). Woven Textiles. New Delhi: Wood Publication Limited.

- Gokarneshan, D. N. (2009). Weaving Preparation Technology. Delhi: Abhishek Publicaions.

- Kadolph, S. J. (2006). Textiles. New Delhi: Pearson Education.

Muchos Gracias for your article. Fantastic.