Recipe of Denim Enzyme Washing Process : Easy 7 Step

Introduction

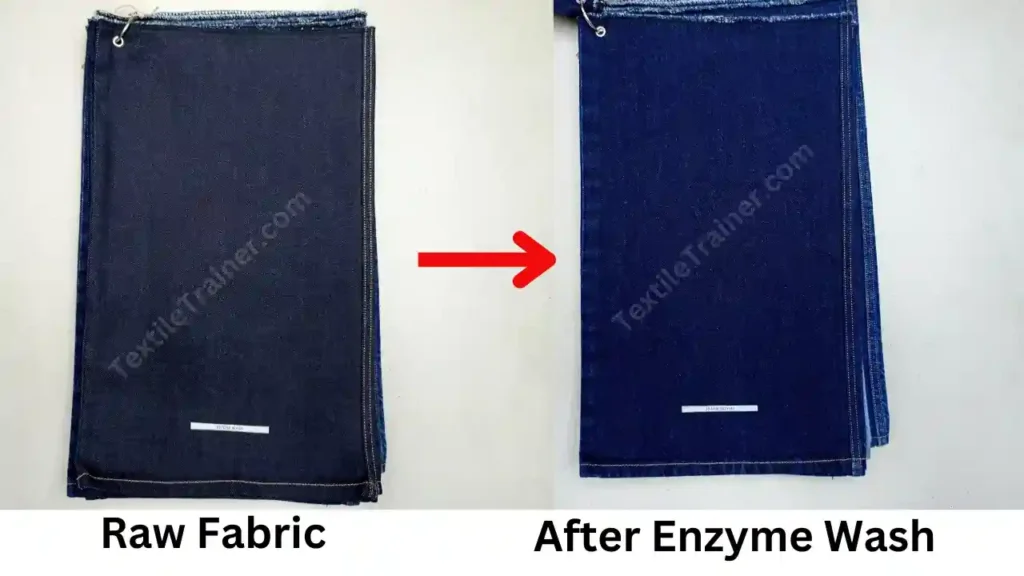

Are you searching recipe of denim enzyme washing process? if yes, you clicked in right article which is about denim enzyme washing process with recipe which is collected from garments washing factory. Enzyme is one kinds of protein which is found from fermentations process from bacteria and fungi. These bacteria and fungi is exist in natural. Enzyme attach the cellulose portion of cotton. Consequently, indigo color comes out from denim fabric and fading effect is created on denim fabric.

What is Enzyme Wash?

The wash in which enzyme is used called enzyme wash. Enzyme wash is used in garments washing factory to create fading effect on jeans pant. Enzyme also work as de-sizing agent and cleaning agent.

Objects of Enzyme wash

Objectives of enzyme washing process in garments washing factory is given listed below:

- To remove size materials presents on jeans pant.

- To achieve high-low abrasion effect on garments.

- To make more soft of garments.

- To increase color fastness properties of garments.

- To improve the anti-pilling properties of garments and gives a very smooth surface of jeans pant.

Types of Enzyme

Generally, cellulosic enzyme is used in garments washing factory for jeans wash. There are 3 kind of cellulosic enzyme is used in garments washing factory. They are:

- Acid enzyme: The color of acid enzyme is slightly brown and it pH range is between 4.5 to 5.5. For acid enzyme, temperature should be between 400 to 550 C. Acid enzyme work within short time. Hence, production is high.

- Neutral enzyme: The color of neutral enzyme is white power form and it pH range is between 6.0 to 7.0. When you used neutral enzyme for jeans wash, you should keep temperature between 400 to 600 C. But, natural enzyme work very slowly. So, it is good for dark shade enzyme affect.

- Bio-polishing enzyme: Bio-polishing enzyme is being used to have protruded fiber removal from jeans pant surface. It also work in temperature between 400 to 600 C. Bio-polishing enzyme also widely known as anti pilling enzyme.

N.B.: Neutral enzyme gives better result with very less back staining but more time. On the other hand, acid work within short time but with too heavy back staining. Now-a-days garments washing factory needs faster results with less time and less back staining. Hence, chemical specialist combined neutral enzyme and acid enzyme in such way which is work faster with better results and cost effective. These types of enzyme know as Hybrid Enzyme.

Flow chart of Denim Enzyme Washing Process

Flow chart of denim enzyme washing process is given blow.

Recipe of Denim Washing Process

Recipe of denim washing process is given below which collected from a famous garments washing factory. These recipe is for 100 pcs garments ( weight about 70 kg).

| Process | Water (L) | Time(min) | Temperature (C) | Chemical Name | Chemical Quantity |

| De-sizing | 500 | 10-15 | 60 | L.P-30 | 250 gm |

| Anti-creasing agent | 350 gm | ||||

| Mesoft-CCS flakes (Cataionic) | 2 kg | ||||

| Rinse | 1000 | 3 min 2 times | Cold | ||

| Enzyme | 500 | 15-20 min ( but time is depend on desire effect. Machine will be running until desire effect found) | 45 | Enzyme | 250 gm |

| Acetic acid | 350 gm | ||||

| L.P-30 | 250 gm | ||||

| Rinse | 1000 | 3 min 2 times | Cold | ||

| Clean up | 500 | 5 | 60 | Hydrogen per-oxide | 600 gm |

| Detergent | 250 gm | ||||

| Rinse | 1000 | 3 min 2 times | Cold | ||

| Softening | 500 | 5 | Cold | Mesoft-CCS flakes (Cataionic) | 4 kg |

| Hot Dryer | 30 | 80 | |||

| Cool Dryer | 10 | Cold |

Denim Enzyme Washing Process

Denim enzyme washing process is described step by step below.

Step1 : De-sizing

Size materials is applied on warp thread to increase the strength of warp thread. Hence, weaving efficiency is increase as reduce warp thread broken due to the frication of warp thread and heald eye. However, these size material creates unavoidable problem in denim washing. Hence, de-sizing process is done to remove the size material from denim pant. Working procedure of de-sizing process is given below.

- Initially, Selected lot is weighted.( weighted 100 pcs garments and weight is about 70 kg)

- Then, loaded the garments into the washing machine.

- Takes 500 L water

- Now, running the washing machine and set the parameter ( temperature 600 C for 10 min)

- Next, add the chemical according to the mentioned above recipe.

- After 10 min, drop the liquor and rinse the garments 3 min 2 times by cold water and drop the liquor.

Step 2: Enzyme Washing Process

Working procedure of enzyme washing is given below

- At first, take 500 L water in the washing machine.

- Added the chemical which is mentioned above recipe.

- Now, set the parameter of the washing machine and run the machine. ( Temperature 450 C for 20 min. Enzyme time is not fixed. After 10 min, check the enzyme effect under water bath. Running the machine until get desired enzyme effect)

- After getting desired enzyme effect, rise the temperature 900 C for enzyme killing.

- Next, drop the liquor and rinse 2 times for 3 min.

Step 3: Clean up

- Initially, takes 500 L water in the washing machine.

- Added above recipe mentioned chemical.

- Run the machine at temperature 600 C for 5 min.

- Next, drop the liquor and rinse 2 times for 3 min.

Step 4: Softening

- Takes 500 L water in the washing bath.

- Added softener.

- Run the machine for 5 min at room temperature.

- After 5 min, drain the bath.

Step 5: Hydro-extractor

After softening process, unloaded the garments from the washing machine and send to the hydro-extractor section. Hydro-extractor remove the excess water from the garments.

Step 6: Dryer

- Load the garments in the dryer.

- Set the temperature 800 C for 30 min.

- After 30 min, run the machine for 10 min in cold dryer.

- Check and unloaded the garments.

Step 7: Inspection

Finally, garments is send to the quality control section. After checking the garments then good quality garments is ready for delivery.

Enzyme wash on denim pant

Problem of Enzyme Wash and Solution

Problem of enzyme wash and solution is given below.

- Sometimes pocket is bleeding due to enzyme wash. Antiback stainer should be use properly.

- Garments hem and seam area damaged. To solve this problem, proper timing should be maintain properly for abrasion and damages protect.

- Garments color bleeding and sometime more or less abrasion come. Enzyme percentage should be maintain according to samples recipe which is developed in R&D department.

Watch the video about enzyme washing process

FQA

1. Are enzymes Safe for health?

Since thousands of years ago, enzymes have been safely used in the production of wine. Aside from beauty and oral products, enzymes have also been used in textile factories, garment washing factories and automatic dishwashing detergents over the years. In the end, however, all jeans pants are commercialized once their safety has been confirmed. So, we can say, enzyme wash is safe.

2. Are enzymes harmful to the environment?

Enzymes are biodegradable, and their waste streams are relatively harmless to the environment. Enzyme use has a positive impact on the environment in several ways, including saving energy and water, replacing hazardous chemicals, and maximizing raw material efficiency. To conclude, enzymes are less harmful to environment.

Conclusion

The enzyme washing process involves using enzymes to clean clothing or finish fabrics, especially in the case of jeans and other worn-in garments. In this article is discussed about denim enzyme washing process step by step in garments washing factory. You can follow the above flow chart for enzyme wash in your factory. However, If you have any question about denim enzyme wash on jeans pant, feel free to ask me below comments box.

You May Read

- Latest Flow chart of Garments Washing Plant with Easy Short Description

- Most Common 10 Dry Process of Garments Washing with Easy working procedure and Proper Figure

- Easy 10 Differences Between Hand Sanding and Sand Blasting in Garments washing

- Top 25 Chemicals Used in Garment Washing Plants and Their Functions: Easy Guide

- Top 15 Best Jeans Brands for Women in the World

- 20 Most Important Machine Used in Denim Washing Plant is Describe Easy way

- Best 10 Jeans Brands for Men in the world

- What is Garments Dyeing? Types of Garments Dyeing Machine Used in Garments Washing Plant

- 10 Most Important Difference between Denim and Jeans

- What is Denim? A Brief History of Denim is Described in Easy way-2023